| Date: 05-19-2019 | |

| Number of Hours: 6 | |

| Manual Reference: no ref |

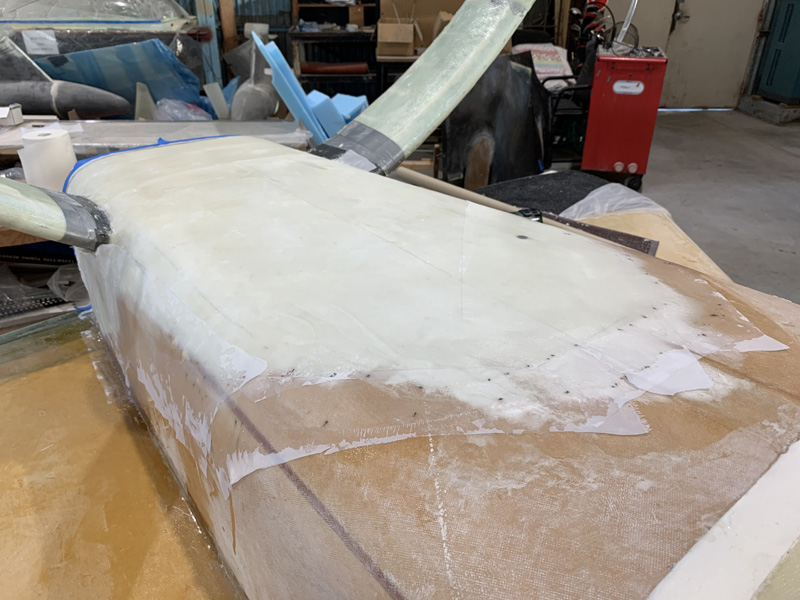

I opted for 2 ply of BID at the usual 45 degree bias with the first ply overlapping the second. While it is non structural in that it is only covering the hellhole area I hope that it gives additional rigidity to the landing gear area and boxes in the area leading to the cowls.

There is quite a lot of glass in this layup and I had to work out a way to cut it so the gear legs would be wrapped but the layup not compromised. I used a piece of plastic and got the size and where to make the cuts by playing around with that. Easy.

Having cut two pieces on the floor using this plastic template I did a little more micro fill and then wet out the target area with pure epoxy for the usual prime. Again the plastic was handy for positioning the first ply on the fuselage bottom.

Here’s where I made the first of two cuts around the gear legs.

The second cut was along the gear at the bottom. If you understand what I mean you can see the result here that gives me the one inch or so overlap I wanted.

The two ply layup is now done and that part took a bit over four hours by the time the peel ply was on.

I’m happy how it worked out around the gear. I trimmed the glass at the edges and had a little glass to glass bonding on the bottom of the strake at the rear to tie it all together.

While not that pretty it has worked out very well on the bottom too. Once cured I can do a tidy up around the gear and mark out where the hatch is going.