| Date: 10-27-2012 | |

| Number of Hours: 10 | |

| Manual Reference: 9-1 |

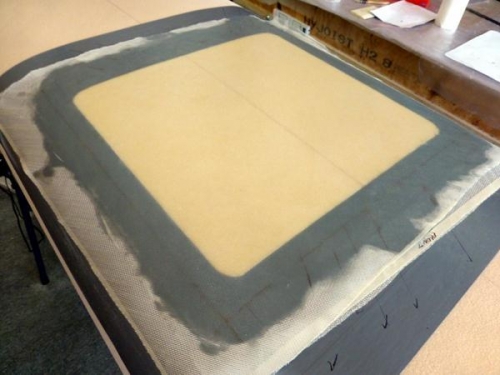

Here we use duct tape to make the outline of the brake. While we are trying to minimize later micro fill there will be a small amount about the thickness of this tape so I was careful to keep it only one layer thick even in the curved edges.

This is where we make our flange that will later be glass to glass so we go well over the .9″ outline and this will be later trimmed back. I used a lot of extra tape as I didn’t want any epoxy on the bare fuselage bottom.

After micro slurry of the brake core I used two plies of UND at 30 degrees to the centerline on the first ply and then 30 degrees opposite on the next ply. It is detailed in the Cozy plans which I’m using in conjunction with a set of the Varieze brake plans (image 3) while still aware of the Long-EZ fuselage bottom layup requirements.

The next step will be to get the brake off the fuselage after cure… should be fun….

Tape the release outline

2 plies on the outside

Planning…..