| Date: 11-20-2017 | |

| Number of Hours: 15 | |

| Manual Reference: no ref |

It looks like it’s easier to post many days work at once. My old logging system didn’t allow for that but now I have my own website. Well….. guess who’s the boss now.

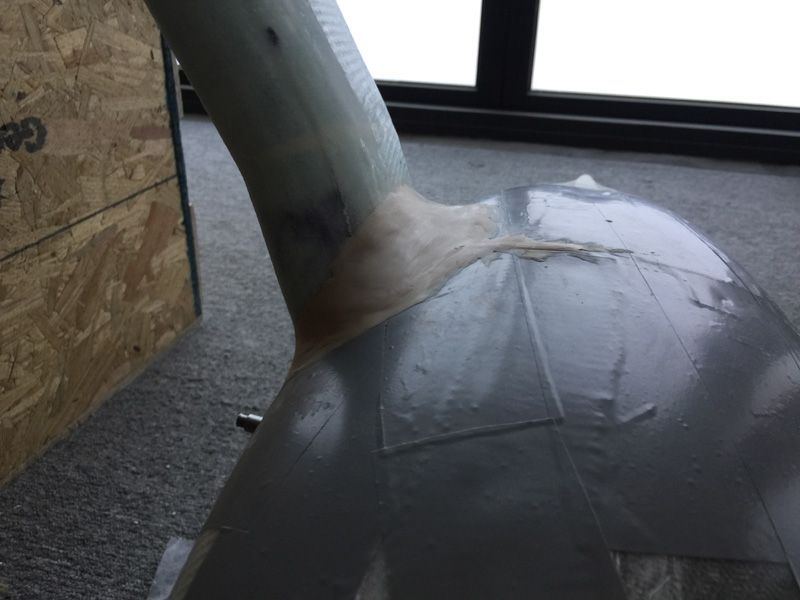

Here’s how the fairings look with the layups done and the pants back on. From here I needed to make some decisions. The intersections at the fairings and pants were not ‘favorable’ or less than 90 degrees so I definitely needed a fairing for the fairings at the wheel pants.

The next decision was will I go with the mounting system I have with the existing screws and hard points or will I go for a bonnet per Gary Herzler’s pant instructions? I’m going for a bonnet as I’m worried about the tire clearances and a bonnet with fittings on top will allow me to ensure I get those lightweight floppy sided pants sitting away from the tires.

So a bonnet means I need a bit more meat on the pants where fasteners will go bear the gear leg cut outs. I went for a 4 ply BID layup and you can see the pre-preg items in the pic below.I added some tape and cardboard so I could just glass across the openings to cut out later.

Here are my cutouts all glassed up again. I’ve gone for just under 1.5″ around the cutouts to ensure plenty of support.

All that time spent making the cutouts nice can be redone now as I have filled in all the gaps. A smarter person would have done that first and saved half a days work…

Another issue has cropped up that I was worried about. I need access to put the brake fittings on and I need maintenance access in case they leak or something one day. I can’t just put the fittings on and glass over. I spent a couple of hours re checking where the pants sit and then cutting out gear leg fairing material below those lines. A smarter person would have already had those lines drawn some time ago.

I checked with spanners to ensure that I have good access. I may cut off that bit at the leading edge but it may be a good place to secure the relief tubes so I’ll leave them for now. You can see the stainless steel brake lines next to the plastic tubes. There is plenty of room for fittings. I think I’ll blow out the lines later in the build before putting the fittings on ‘permanently’.

A few more hours again on my knees refitting the pant cutouts. I also enlarged a couple of screw holes to make the pants fit in a more ‘relaxed way’ Its a lot of fiddling I know.

The cutouts are a better fit now, of course I’m the only person who will know as the bonnet will cover this join anyway. Maybe I can remove the pants some time and then get a big mirror underneath to show people. Of course even if you are reading this even YOU may not care!

From this point I’ve added release tape and started making clay intersection fairings which will become the bonnet.

I have more to do on this. Its another skill I am to learn, sculpture… who would have guessed this would be needed to build an airplane? Ok, be nice, I haven’t finished yet. The fairings or the plane.