| Date: 06-13-2019 | |

| Number of Hours: 14 | |

| Manual Reference: no ref |

I thought the gear leg fairings were pretty much done two years ago. I was wrong.

A very knowledgeable friend noticed my fairings in a photo and asked if I was going to fix them. He said they were at the wrong angle at the fuselage. I first established a line parallel with the longerons but close to the fairings so that I could do some measurements.

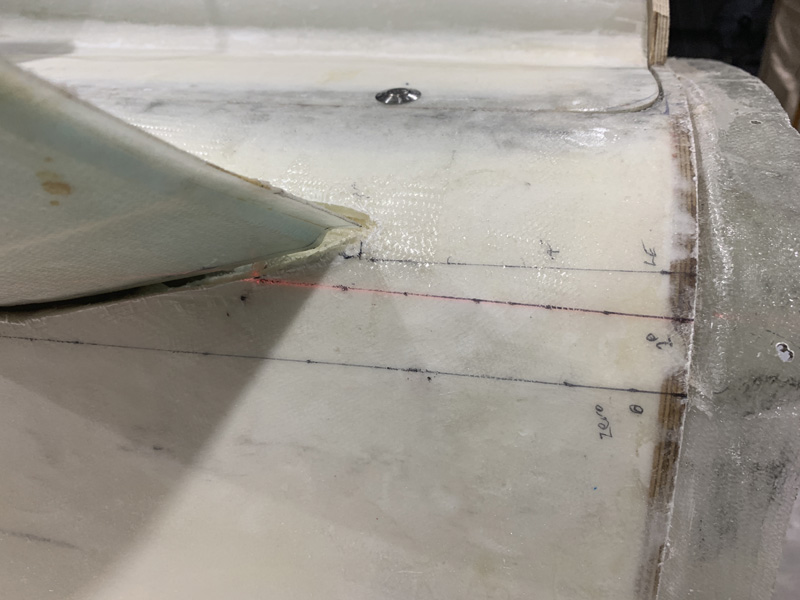

My fuselage is on an adjustable stand. This made it was easy to get the nose into a 2 degree up angle with the self leveling laser and a spirit level to draw in the lines I needed.

The gear at this point should be in line with the air flow with the plane at cruise angle. That would be about 2 degrees nose up at maybe 180 knots. My flying EZ is 2.6 degrees nose up at 140 knots so I’m thinking a little flatter when you are faster. That trialing edge should be where the red laser line is.

My gear is 2 deg trailing edge down. Its should be 2 degrees nose up! Opps. I am 4 degrees out or 0.8″ wrong at this trailing edge against the fuselage. When doing the install ages ago I found my Eureka pre cut fairing pieces fitted in only the one place. At the time I didn’t really understand where it was meant to be. Now I do. WRONG! …so I picked myself up, dusted myself off and went ahead with a fix. Only looking forward, never back. A lot of dusting myself off was to come.

I decided to do one leg at a time so I could use the existing gear for measurements. Out came some sandpaper on an air power tool. In an hour or so I had a pretty sad looking gear leg. Another hour or two got the underside (or top side as we are inverted) in the same distressed state. The angle is pretty good at the tire pant end which meant I could at least leave that alone.

Next up was a lot of pour foam. That stuff is really hard to get upside down. I had a few goes at that until some sort of technique evolved. Not really pretty is it?

I made rough templates from the CNC cut cores that the fairings came in. Fortunately I saved these and given they are a negative of the cut piece I just traced the shape on some cardboard and cut them out. Instant (quick and dirty) template.

After a loit of hand filing I got the profile you see above and with time had this all the way down the leg.

The under side was much harder, only because it was…the underside. I still got there.

This shot gives you the idea that I’m close to a good profile and ending at the correct place now 0.8″ (up) from where the airfoil was. It looks better in real life and quite accurate. After fiberglass and a light fill it will be excellent. That’s my plan anyway.

Before glassing the gear here I felt the need for a coat of micro to stabilise the foam and fill in the ‘porous pour foam’. It will probably need another coat after cure that I will then sand for a good bonding surface. Given the cold weather here I may be two days in between coats.

Meanwhile before I went home I spent another couple of hours getting the left gear leg in a distressed state ready for battle tomorrow.