| Date: 06-30-2019 | |

| Number of Hours: 16 | |

| Manual Reference: no ref |

There needs to be a small gap between the fuselage sides and the main gear. Obviously when the main gear is loaded with the weight of the plane, with different fuel loads and when landing or even with a small bump during taxi, the gear will flex. If the gear fairing is just bonded to the sides, that join will crack.

The other issue is that we need to smooth the flow of air here to reduce ‘intersection drag’.

I spent a while getting a little former made for the aft curve. I tried stiff cardboard first. It tended to droop a little so some scrap metal did the job. Who doesn’t like doing things twice?

I used just a hint of hot glue to get the little extensions sitting right.

I had some modeling clay for making the curves. Yes two types.. this is the wrong type. Its too stiff or maybe it is too cold in the hangar, middle of winter here after all. I pressed on anyway.

I was determined to just get this done and was less interested in the perfect job as I was getting some tape on that ugly clay mess.

Late that night two plies of BID was wrapped around each leg. As I was driving home after a day too long I thought of all the things I could have done better. Particularly at the trailing edge where there were now 4 plies if you include the wrap of the ends. Way too much for a crisp result. I also thought about how I should have used some light clamps at this trailing edge to pull it all together.

Two days later after the cure I managed to get both fairings loose, clean up underneath and begin the trimming process. A much smarter person that I would have done this job before installing the wheel pants. There is a cuff now that prevents removing these fairings from the gear leg for a MUCH easier clean up.

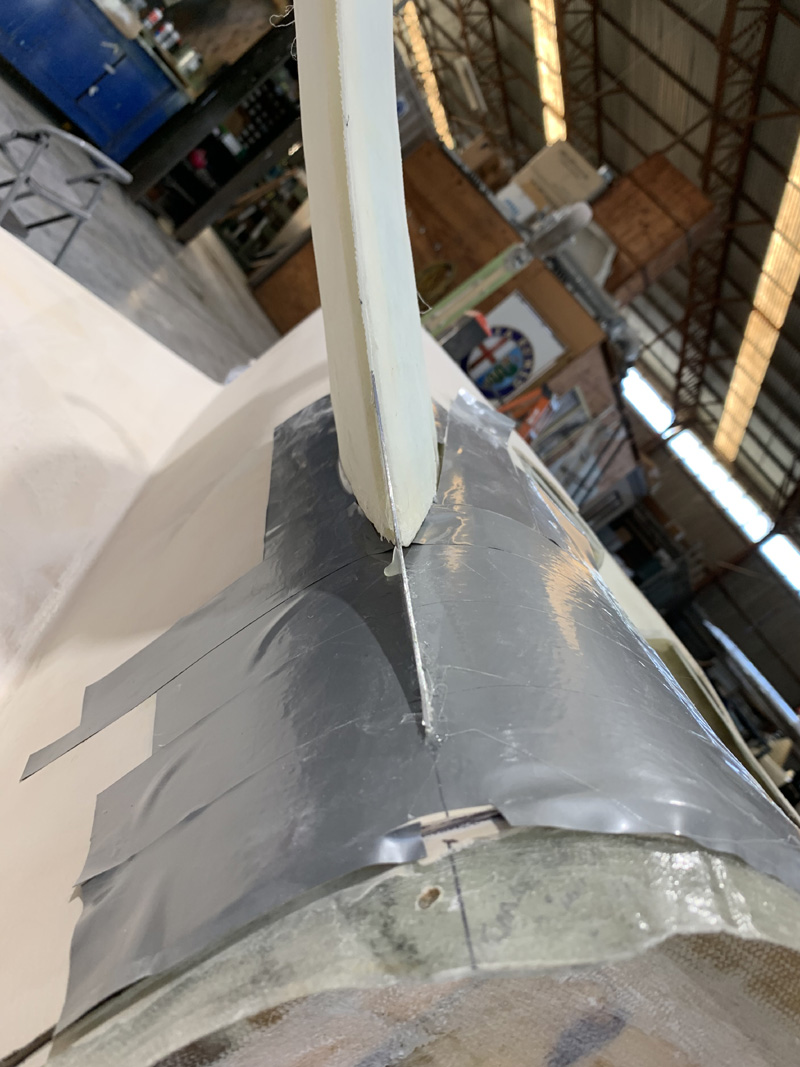

This illustrates the concept. The fairing is bonded to the leg just away from the fuselage with no load as it will be in flight. With a load on the ground the flexing of the leg will move the fairing away from the fuselage.

This is getting closer. I think those trailing edges are too thick. After this shot I filled the fairing with a little flox and micro mixed. After that cured, I removed most of it and then had a bed to thin those trailing edges from the outside with a little meat in them. I’ll get them nice.

Meanwhile I needed to get those fairings on for real. I used cardboard spacers and floxed the top of the fairings in place where they met the gear leg. To be tidy, I added one ply of BID as well. The clamp’s are to ensure nothing moves and that gap at the fuselage remains close.

Don’t even ask me how we are going to paint this so the intersecting gap remains. I’m thinking razor blades and a careful line. Yes I need to do some filling, yes I’m not 100% happy but these did happen quickly and I’m a man on a mission. The clock is ticking. There is all the time in the world for safe. Plenty of time for good. No time left for perfect.