| Date: 09-29-2021 | |

| Number of Hours: 25 | |

| Manual Reference: 21 |

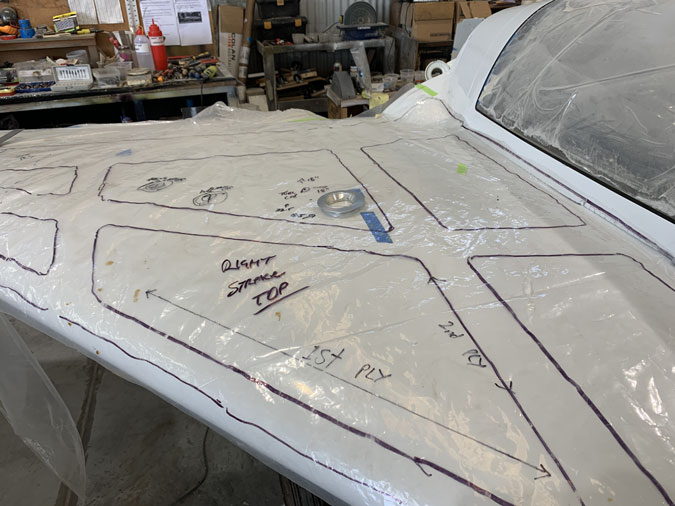

Now the strakes are beautifully painted I need to cut two big holes in them for the fuel caps.

The exact position for the fuel caps just took too long. When I built the strakes I made plastic templates so I would know where the flanges were to allow the caps to go close but not on top.This is for strength.

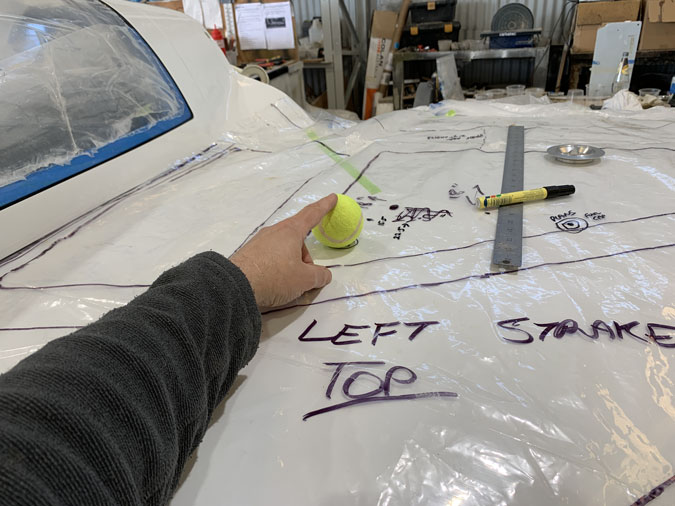

I used the tennis ball to help visualise what would happen if I spilled fuel. I wanted to gauge the runoff and its direction relative to the caps.

I didn’t want to be too near the passenger and right in the middle of the highest point would give me maximum fuel if I ever wanted every drop possible. The downside of this was it put the caps too far from the leading edge to be comfortable when juggling a heavy fuel nozzle. It also had me or a refueler leaning well over my nice pretty paint with rivets in jeans scratching my while plane. Hey!!

I ended up going on the ‘down slope’ after calculating how much less fuel I would carry if the caps were in a sensible position. The answer was less than a liter fewer a side.

Marking this out after measuring and remeasuring and second guessing myself over a few days was a big deal.

Once I had a tiny hole marked it was on! This first hole took ages, the second one happened in about 20 minutes.

I used lots of toys including the improvised sanding drum aka red tape with sandpaper glued to it.

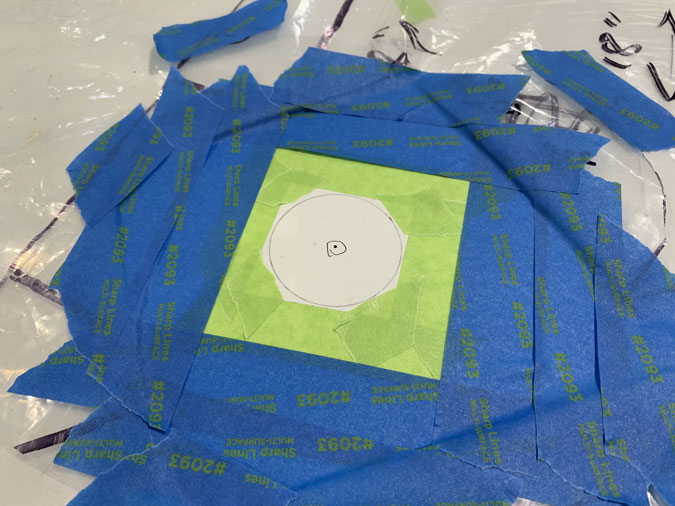

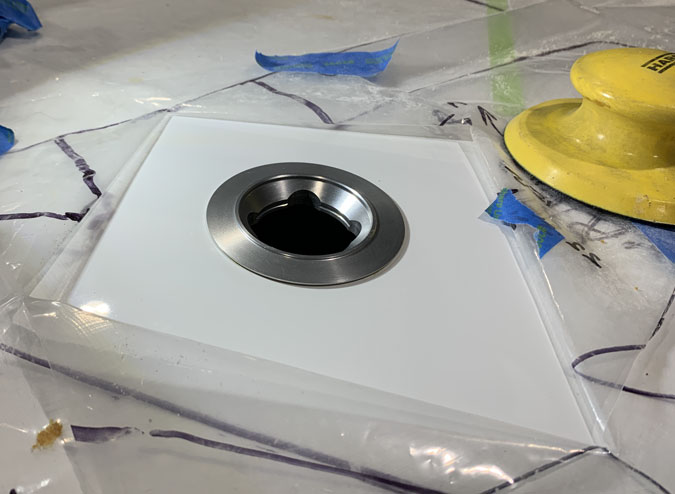

You can see I have just gone down to the inner skin at the bottom. At the sides I have removed material so I can get flox under the top skin. When that bonds to the fuel cap to will give extra strength to hold the cap in place.

I made a bunch of key holes via a round bit to give the flox something to grab onto. I also roughed out the cap bottom with 80 grit after this photo. I took the shine off the key surface paint as well.

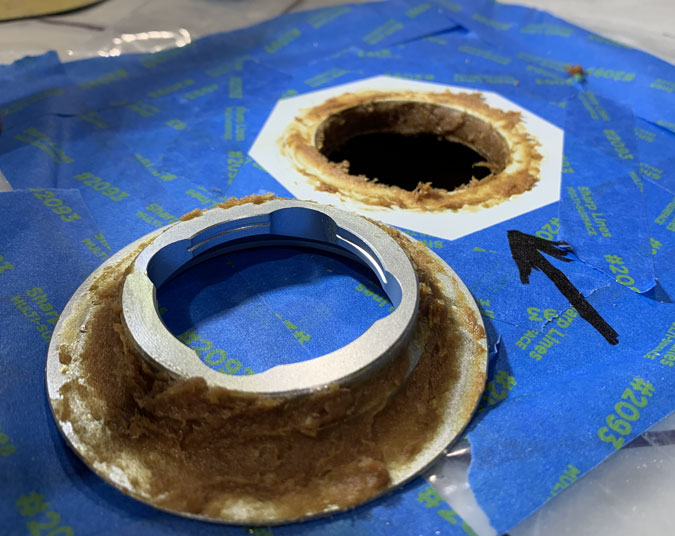

Then I had to cut through the hole to the tank itself. I had my vacuum cleaner on hand and if any debris got in the tank it is too small to see. I will be flushing fuel though them later when I do W&B.

Given I am not exactly to plans on this I want to weigh with different fuel loads when I have the aircraft scales hired. That’s when the fuel calibration will be done.

I used a lot of flox and cleaned up a good squeeze out. I think there are no voids to worry about. I used the same epoxy the tanks were built with. Old school and proven fuel safe over many years.

The fuel caps are now permanently in place.

A very important safety item is to ensure the caps do not depart the airplane if they are not locked in place.

Of course I will never forget this but I’d hate to have even the possibility of a cap go into the prop . I also chose to have the caps inside the prop arc, even when outside of this a lose cap can still make its way into the prop.

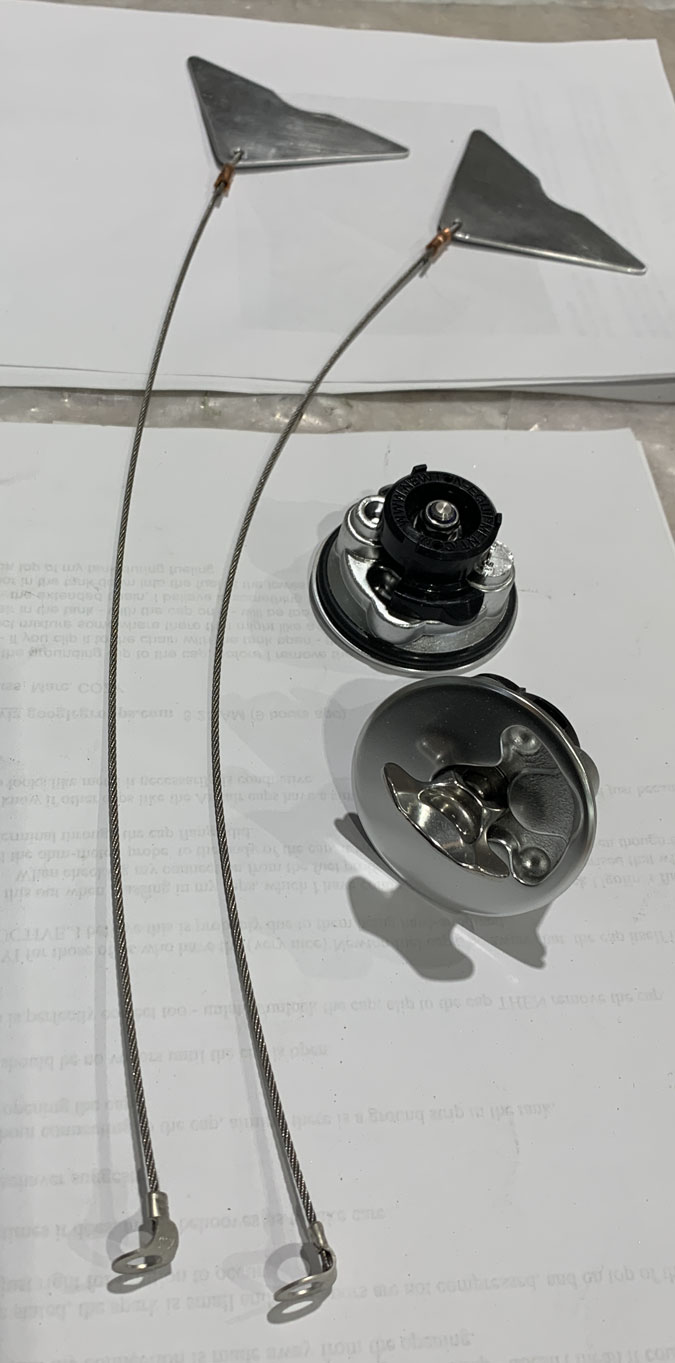

I’m using 2024T3 0.063″ aluminium and shaped so it JUST fits sideways in the fuel cap opening. Once tethered at the apex it will keep the cap from departure.

The length of the cable allows the triangle to sit on the bottom of the tank even when the cap is off and resting nearby.

I used simple attachments and rudder cable, During refueling an earth strap can go on the cap latch. The other end needs to penetrate the surface of the fuel. The body of the cap is ‘coated’ and will not earth, so use the latch!

I have also put some braid inside the tanks so earthing is possible from the external vents assuming I connect them at the vent manifold. There are options. The cap seems the simplest.

Touching the fuel nozzle to the cap latch initially may be good practice. However the fuel running quickly through the metal hose also builds up static.

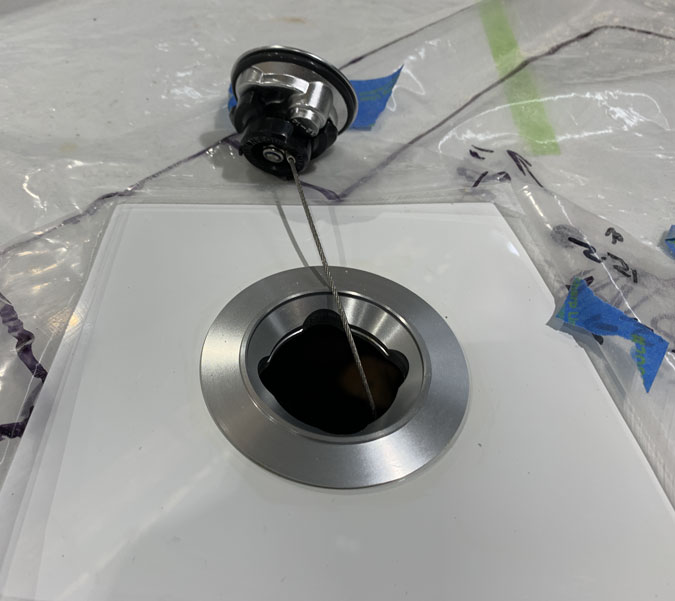

This is how it will go during refueling. If I’m smart I’ll have a rag handy to put on the strake.

Cap in place, job done.