| Date: 03-16-2016 | |

| Number of Hours: 10 | |

| Manual Reference: 16-1 |

To make the front side consoles removable I first needed some hardpoints. I simply marked out where the screws were going, made a void with a drill and filled the area with flox. You can see this in pic 1. I was just after something to have the screw go through that was not going to collapse if the screw was quite tight…like soft foam might.

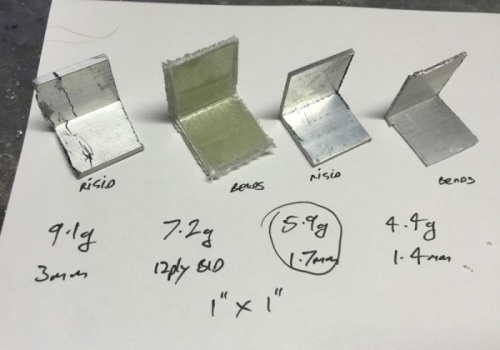

Pic 2 shows the decision on the lightest yet strong enough option for the brackets. These are 1″ by 1″. I found even 12 ply of glass still quite flexible so weight wise no win here either. The 1.4mm angle I could just bend with my finger while the 3mm and 1.7mm were very solid. The arm rests really don’t take any loads so I went with the 1.7 angle. It was labeled at 1.6mm at the store and was unequal being about 1.5″ on one side. So I sorted that out and as usual took my micrometer to this local aerospace store as I don’t trust their numbers.

Pic 3 shows that I’ve cut up a batch and added lots of holes for floxing to the cockpit floor. These will act as ‘fingers’ helping to hold the brackets in place. Aluminum is a good material given I’m going to be riveting nut plates on.

Hard points

Bracket weight check

A gaggle of brackets