| Date: 10-01-2023 | |

| Number of Hours: 28 | |

| Manual Reference: 23 |

These are the little jobs that just take forever.

I finally had the little side pieces fitting OK.

The gaps weren’t too bad.

I progressed to drilling out holes ready for the nutplates.

Now was as good a time as any to square off the rear of the cowls

It took a while and I mainly eyeballed it. You know “to a pleasing shape”.

Not too bad.

OK, enough gratuitous spinner to cowl pics.

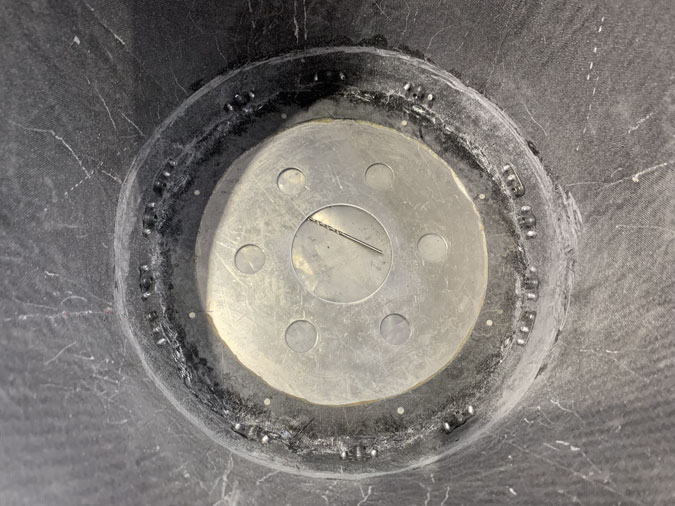

I added two plies of carbon to the inside thickness of the nutplate area because I had to countersink the rivets. I also had to use pull rivets given its a difficult place to get my squeezer into.

It worked out pretty flush so the spinner can go back on.

The screws are pretty tight in new nutplates but it seems to be working out. Maybe a coat of black paint on the final screws if I decide to clear coat the spinner.

When I put the screws in the side pieces, they moved just a little and looked pretty ordinary with large side gaps. So I decided to make new ones.

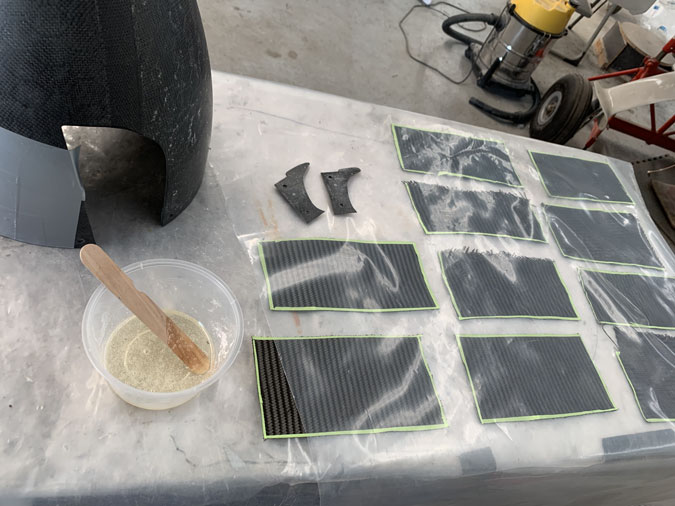

This is 10ply of carbon to get the required thickness and laid up on the spinner for the correct curve.

Here’s what I’m replacing. It probably doesn’t matter. I am trying hard not to drop my standards.

OK, this is a better fit now. Not perfect and it took SEVERAL days! …but better.

Lets call the spinner installed for now. It still needs a minor tweak. That all said, ENOUGH!! …for now. I need to keep moving.