| Date: 12-02-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 11-1 |

As happens so often I got a little nervous wondering if those NC1 lugs were in fact installed the right way around. If I had it wrong.. this would wreck the cores. I was only 90% sure I was right. In the end I drilled out the two rivets and tried the lugs the other way around.. pretty easy really.

I had a scale drawing of the canard and where the hinge pin goes was .4″ different to the way I had it and reversing the lugs might make mine per the Roncz drawing. Well……. what do you know. Reversing them means the rigging jigs cannot be fitted. Great so I had it 100% right despite the drawing. I riveted the lugs back in, this time knowing I’m correct. It was a few hours well spent in the end. Best to be sure.

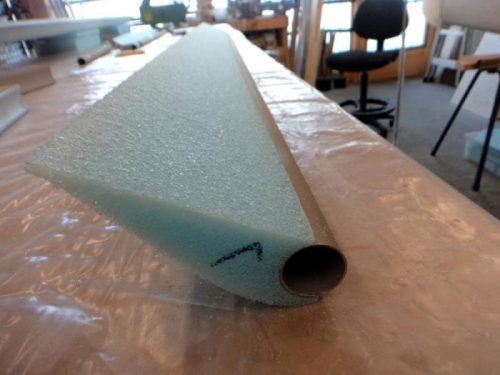

All this was after I had carefully sanded the cores so the tubes could be pressed in place. I cleaned the metal with a wipe or two of acetone and mixed some epoxy for the micro and pure. Of course I’d spent ages doing trial fits and working out how to secure things while it cured.

You can see in pic 2 those little triangles which are the rigging. These need to be flat when the bottom of the elevator is flat. This ensures the foam is in the right place on the tube relative to the lugs. Got it? I only have two jigs so each elevator was done on separate days after the first one cured.

Pic three shows them both done and the nifty profile templates. The gap in the pic is allowing for the thickness of the glass. I had to do a bit of smoothing out too when it joins the tube in prep for the skins.

Make it fit

Rigging jigs and glue

Tubes on the cores