| Date: 07-21-2024 | |

| Number of Hours: 0 | |

| Manual Reference: 23 |

The engine has been started, installed in my airframe. July 21st 2024. Yes it was previously run in a test cell in the USA for 25.2hours. This milestone is my first run in VH-XEZ. It was quite a journey sorting out the many engine problems, with a few still to be resolved.

Here’s the ‘money shot’ or rather video.

There were a LOT of tries this day as well as the week before. Lets roll back some time to when I thought we were going to get a start. I was planning by June 30th but that line in the sand came and went. We had coolant leaks to deal with. We got all that sorted out, although after the above start a new leak started up that I will deal with later.

We tried for a first start July 13th, but couldn’t get the engine firing. The best we had were a few backfires. We also had quite an issue turning the thing over with anything like a usual cranking speed. Something was wrong, maybe with the timing or the batteries.

At least I was still near the hangar door.

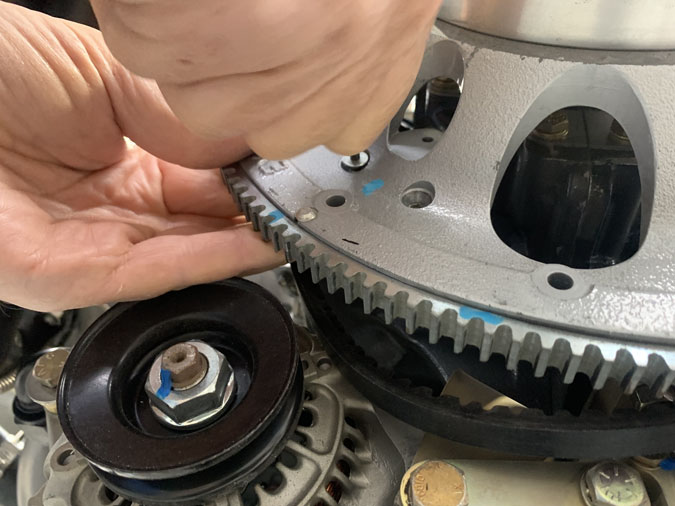

After emails back and forth with Robert Paisley, from EFII, we received instructions on how to confirm the timing. As you may know, the flywheel is located with dowels so it can only go on one way. TDC (top dead center) was where it should be although we checked anyway.

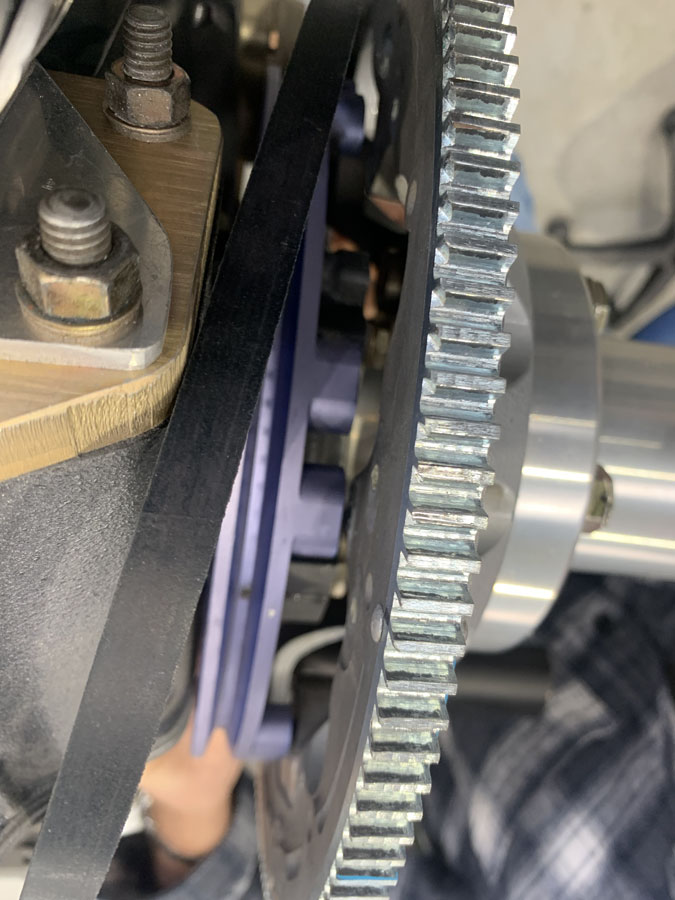

Notice the purple ring that holds the alternator belt? This has a series of magnets in it in three positions. These are what triggers the ignition system.

Yes it is possible to have the purple pulley, the ignition trigger, in the wrong position despite the flywheel being correct. Now you’d rightly say… “but you said the engine has already been run in the USA. So how is it possible to have the timing ring wrong? The engine was delivered with the flywheel attached!”.

Ahhh, one thing we noticed when the engine came was that the flywheel teeth were like new, like the engine hadn’t been run. Our deductive powers went into high gear and we concluded that another flywheel MUST have been used on the engine.

Maybe this lightweight one was misplaced or not on hand when they built the engine? Then they swapped it over at the last minute before sending it over the Pacific to me.

After a lot of head scratching and two tries, we confirmed the flywheel AND the re-positioned timing ring were both now in the correct place.

That’s me on the right. My unnamed avionics and all round expert on so many other things used the battery cart and we connected direct to the starter motor. Yes with the timing in place and enough power to the starter we got ‘the beast’ fired up.

I have #4 AWG cable running from the batteries in the nose to the starter and back again. That’s around 30 feet and the voltage drop with that size over that distance turned out to be a deal breaker. 450 amps was measured momentarily during cranking! A combination of wire too thin and a tight high compression engine.

I have ordered #2AWG CCA wire from the USA to replace what is now in the plane. It is less than a pound heavier and I should have gone with it in the first place.The copper clad aluminium wire is lighter than straight copper and more importantly it has less voltage drop over distance than pure copper 2AWG cable.

This is a pretty big job as the main wire looms have to come out and bigger P-clamps put in. I have to remove the coolant pumps, radiators and a lot of other things to get access. I am also looking at the same footprint batteries but there are some in another brand than the Odyssey PC380’s that have more cold cranking amps. I’ll get one, and if its better, replace the second battery as well. I hope that these two factors will fix the starting issue.

On the plus side, the engine started and its just more money, work and time to fix. I’ll keep pushing.