| Date: 12-13-2023 | |

| Number of Hours: 8 | |

| Manual Reference: 21 |

These vents have been an ongoing issue. I guess I could or should have done them in plastic pipes and it would have been soooo much easier. I had to do it in large diameter fuel line aluminum didn’t I?

I wanted the big bore so that the two tanks could equalise quickly via the common sump and I wanted no leaks or smell in the cockpit.

Given I have so little room in this plane these lines have come in and out several times. Of course being pretty solid I now have to ensure they don’t move and are firmly fixed.

After some work these are getting pretty close. I made fixing points but I now find some of them aren’t necessary.

With the coolant motors now in one of the vents wasn’t going to fit. I made another hole in the bottom of the plane forward of the previous one and of course then the bottom piece wouldn’t fit.

Out came one of these strange shapes for a 1.5″ trim to make it work. Its lots of fun getting these things in and out.

Now we have a fit.

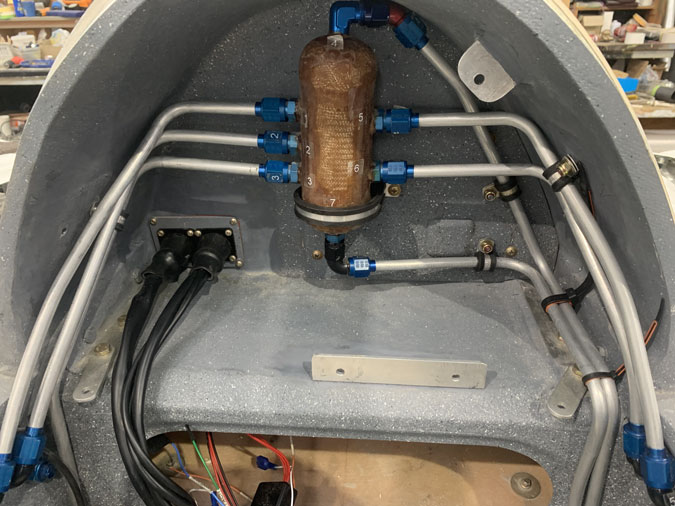

A LOT of thinking went into how to mount the pipes so they are secure. In the end I came up with this strange bracket that gets foxed to the undercarriage bow.

It was a little tricky getting this to work.

Here we are floxed in place and cured. The pipes are now very solid. You can see I’ve trimmed them as well. I have made it low pressure at the back and I think this might be wrong, I might slant the other way for positive pressure into the tanks. I’ve left enough room for the option.

I could argue for both cases. Maybe too much ram pressure would cause fuel to be shunted overboard when the tanks are very full at some angles? Maybe the negative pressure would suck some fuel out? In both cases the fuel would have to climb to the top of the rollover after filling the vent bottle before it traveled downhill to the underside vents. I can’t see it happening, but I’ve been wrong before.

Here we are again, all solid. I’ve used P-clamps and a few quality cable ties. The last bit is the line to the right side of the sump. I will sort that out when the fuel line is done and do them both together.

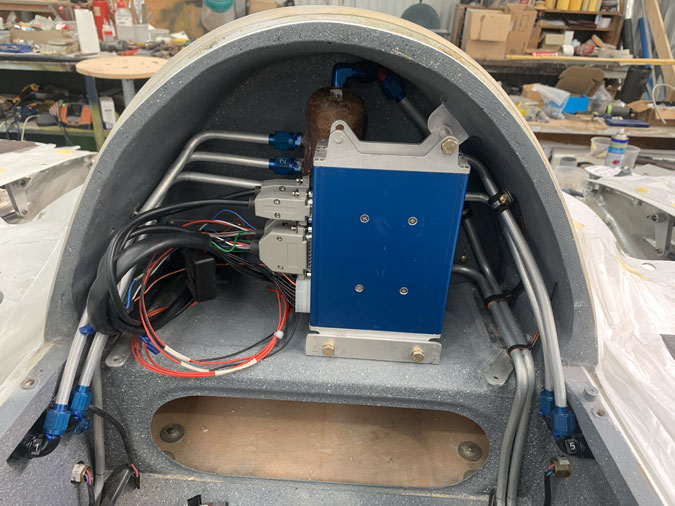

I put the ECU’s back in for now and can see that once wired up, a few hose clamps will neaten up and secure all those wires.