| Date: 05-09-2024 | |

| Number of Hours: 10 | |

| Manual Reference: 23 |

Ceramic coating, done properly, can reduce heat from the exhausts under the cowls by 30%. I want that heat out the pipes not adding to the cooling problems all ‘pusher’ canards seem to have.

This coating is called HP2 Black and was done by HPC (High Performance Coatings) in Leongatha, Victoria, Australia. Turnaround was about two weeks and the coats very reasonable. The job is as good as it looks. I now have to be very careful with the pipes as they will scratch more than bare chrome moly steel.

I got the pipes in and this time with the correct Lycoming steel gaskets and did the nuts up to spec as best I could. I did buy a new offset Snap-on 1/2″ spanner as the pipe nuts are always a wrestling match. I could torque a couple of them to spec and the others had to be by feel. I have no idea how you get a torque wrench on some of them them.

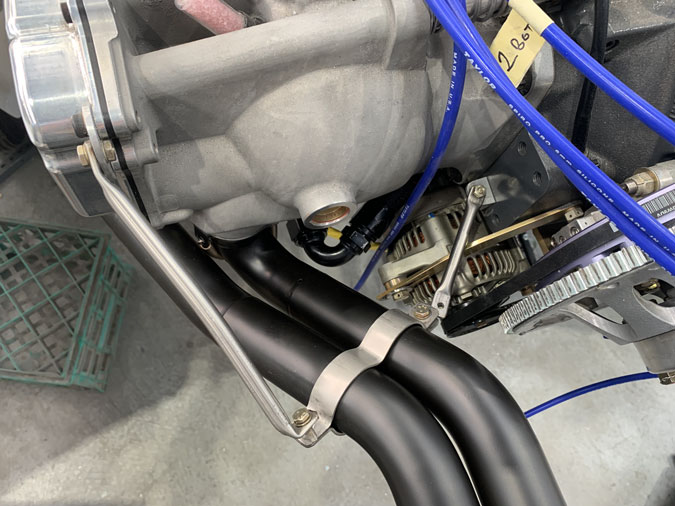

Notice the difference? Yeah, that right angle bend I’d made on the pipe support was going to crack one day. Since making these supports my ideas have evolved a little and using a good 2024-T3 bit of angle as a bracket is likely to last longer. So all those initial supports were replaced. I am much faster doing this work the second time around.

I redid this one too. The way the bracket on the engine is now is can’t rotate easily and it now clears the alternator support arm by a good margin although its hard to see from this angle. It was too close before.

I did improve the clearance here slightly but there is not much I can do about the bend. The support needs to clear the injector. Other methods just introduce alternate problems of a similar magnitude. All my stainless steel supports along with other items will get regular inspections as a part of my maintaining duties.

This one was certainly improved with a bracket instead of a tight bend.

Not exactly elegant but I hope very strong on this outside join. Maybe I will round the corners to make it look nicer. For now, its just keep going.

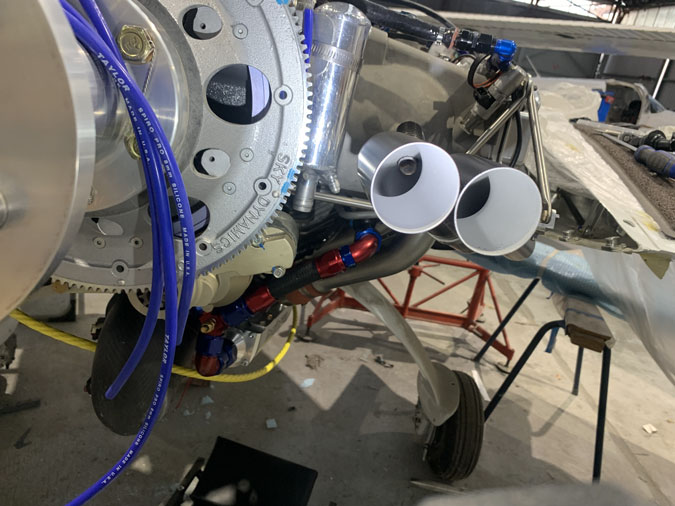

I had pre-drilled holes and had that boss for the air fuel ratio sensor welded on before the coating. Looking back I might have gotten the screw in type EGT’s. Maybe on the next plane HA! They are all in about 2.5″ down from the outlets. While it was just four simple holes I did a while ago, I was very careful to try and ensure the sensors were clear of the pipes, cowls and access to the spark plugs.

The pipes look lean already on the inside. You can see the outlet from the crankcase negative pressure pipe which is a part of the oil separator setup. This should further reduce oil losses in flight and keep things happier in the engine. It also adds another maintaining item as that pipe MUST be clear of buildup. Its a 50 hourly check although initially I will do it more often and see what buildup is occurring, if any.

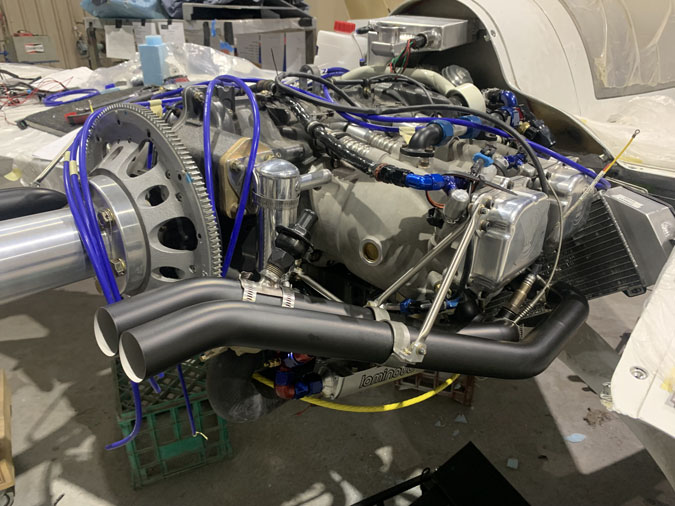

Here’s a bit of an overview. It is going to look messy until I get all the wires back on, connected and secured.

Another overview of my work area.