| Date: 08-29-2023 | |

| Number of Hours: 8 | |

| Manual Reference: 23 |

Time for the first fitting over a couple of days.

I bought a crane from one of the LAME’s (Licensed engineer) in the hangar. The one they use is enormous! First up I could see as expected the standby alternator had to come off as it just touched the firewall. Next up the throttle body had to come off as it would hit the lower cross brace on the engine mount, that was expected too.

With the lord mounts in place I wrestled the engine onto them. All the AN7 bolts are in but I only did up the top two nuts. Its not like we are going flying anytime soon. To be honest I was shocked at the size of the induction and sump that was supplied. As you can see this is never going to fit. It also robs room I need for radiators at the front.

The top cowl fits and we are also good at the sides. While this was expected, it is still a relief.

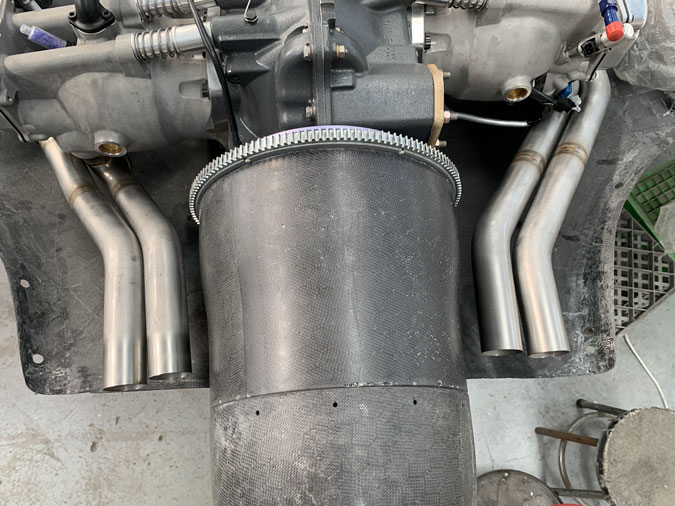

These monsters had to come off next for the bottom cowl fitting. You can see how they go a long way forward at the front which is also not going to work out.

OK! These steel pipes are off and I can get on with seeing what else fits.

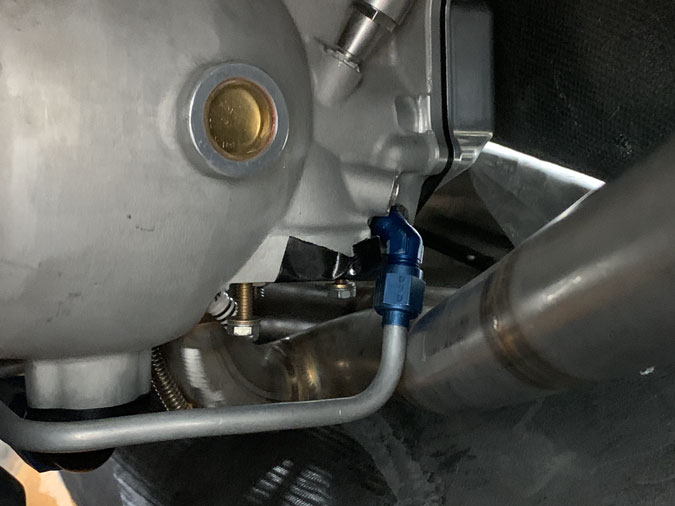

Now the bottom cowl fits (although not done up in the pic). I tried the exhaust pipes but there is an oil drain line on the right side stopping the pipes going to the left nearer the prop hub. That has to come off next…

Here’s the problem. I will go to a straight fitting and make a new pipe. Its 5052-0 I think.

Call me surprised but the pipes fit inside the cowls! There is good clearance at both the top and bottom. The prop extension fits too.

Yeah I can see… the exhaust pipes look a bit high and are nearly touching the top cowl. Well I haven’t tightened up the bottom engine mount bolts yet. I had to make special tools to tighten the top ones and the engine will be coming off soon anyway. Maybe when I do get all the bolts done up it will angle the engine back to where it should be? I think it might. As it is I will be cutting the pipes back an inch or so and that will also improve top cowl clearance.

Next up was trying out the spinner and angling in the pipes as far as they can go. They swivel in the fittings and will need fastening towards the middle or ends. Well I’m pretty pleased with the fit. I had thought these would need remaking. In an ideal world they would point more to the spinner to make it nice and sooty. As it is I’m going to leave them and forgo the small gain that this might bring per CP83 Mike Melvill’s article (for those who care). However I will look into ceramic coating to get that heat away from the engine.

It does look pretty good. Do I really need a propeller?

Clearances are just right although i need to clamp everything down to be 100% sure.

See the previous pic to show the top cowl is not in fact resting on the spinner. Haha!