| Date: 08-26-2024 | |

| Number of Hours: 10 | |

| Manual Reference: 11 |

My elevators just seem too stiff at the stick. It’s has been bothering me for a couple of years. I had a former senior Boeing aeronautical engineer look at it and he said it was safe and being so stiff might reduce the onset of flutter.

While I of course accept this, I’m still the ‘manufacturer’ and it just wasn’t something that felt right and correct. Now I’m about to test fly I wanted to get to the bottom of the problem.

With the usual difficulty I got the canard off. The autopilot servo makes this hard. After several goes I did get a more acceptable method worked out. I had to find the source of the friction. These witness marks of the offset were my first clue.

Here it looks like the marks are mainly on the underside.

It is quite a job getting the elevators out. Two very long stainless steel pins hold them in via three ‘hangers’ per side. I needed to check all the connections to see if there was any galling or if the bushings the pins were going through were too tight.

I checked all the hinges and they were fine. I greased everything while it was out. Getting the pins back in is a job that has driven grown men to tears. It only took me an hour or so this time which is pretty good.

As you can see in the video the elevators are nice and free now. Frankly not all that different to before once it was out of the plane. OK, slightly better. Obviously now, and confirmed with my experimental data, the main problem is when I put the canard back on.

It turned out that there was a little bit of paint at the offset hinge where those witness marks were. That thickness of paint top and bottom, once the canard was back in place and bolted on, created enough friction to be the big issue. I think it was the squeezing that made a clamping pressure.

When the elevators were off I very VERY carefully removed paint under the offset and on the fuselage side as well. I ensured I was down to the bare phenolic which is what I made the ‘seats’ or touch points of the elevator shafts. Any gap here causes a huge chill factor in the cockpit so it needs to be a very close tolerance fit, but not too close as it clearly was after painting.

Here is the elevator reinstalled AND connected back to the stick. As you can now see it is free, it looks and feels right now. I will be happy to fly without concern.

I also revised the springs in the elevator linear actuator which is how the trim is set. I had heavier ones that I tried when the elevator was stiff. Then I changed to lighter to see if that was the problem. Nope. Now I’ve gone back to heavier springs. I can overpower these easily which is important in the event of a trim failure. Maybe they are still too light? I won’t know until I test fly. I should at least get an idea if I can do a fast taxi up to 60 knots or so to see how it feels as the canard flies.

I’ve just done the work on the annual for JZE. I need to be current in this before I begin the test flight program on XEZ. When I say I’ve done this, my work must be supervised by a LAME (licenced) and I can’t sign it out. If I was keeping the plane I could be authorised as I have built one of the same type but it will be going to a new home soon enough.

Interesting to see them side by side for perhaps the last time.

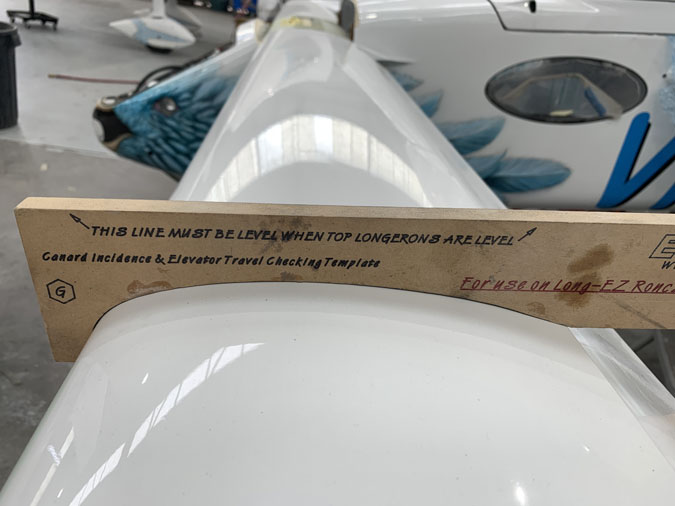

While I had the opportunity, I check the profile of both canards. Here’s the new build, pretty much as it should be.

Here’s JZE, slightly different at the LE. The canard flies at 65 knots on this plane. I wonder if XEZ will fly closer to the 60 knots mark which is more usual for the Roncz canard? Then again in might be the lower AofA that JZE has being slightly nose down with the gear fully down. XEZ is set slightly nose up on the ground so this should make a difference on take off.