| Date: 11-26-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 11-1 |

It is ridiculous how long this step has taken. Elevators are another part of the build that seems like secret builders business and hard to get my head around. I’m being extra careful too as mistakes here would delay the project. This seems to make me a little dumber than usual in that I want to ensure everything is right. So it took a few days to cut a couple of tubes to length and stick in 4 rivets.

First up I tried the long stainless steel hinge pins in the MKNC-12A’s. Of course they got stuck and an hour or so freeing them without damage suggested a new plan was needed. I ended up sourcing an extra long 3/16 drill bit and cleaning out the hinge holes. Ha! Just needed a tickle. I checked everything else that was going to end up on those hinges too.

Then cutting the tubes to length, measure 50 times cut once…and I did. Just .05″ off one end and then quite a bit off the LHS tube. I spent a few hours checking and rechecking. Then I did the cuts on the bandsaw, squared them off and finished with fine sandpaper to remove any possible stress risers.

I spent more hours to ensure the NC2 lugs were in the right way. They can go in two different ways and I finally confirmed on a website that I’m not the only one who found this tricky. Enough to say they go hinge hole down not up. If you are doing this you’ll know what I mean. I kept checking and rechecking anyway. Hmmm seems I’m beginning to understand this simple step.

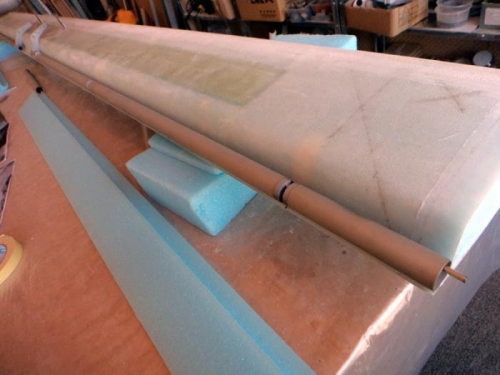

Trial fit

Tubes cut to fit, middle one later..

Hinge trial fit is all OK