| Date: 05-23-2015 | |

| Number of Hours: 10 | |

| Manual Reference: 19-18 |

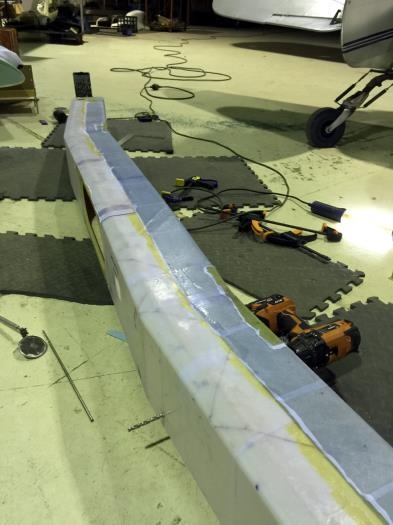

A few more sessions and I had my bolt hole positions marked out. After all this, the variations from the plans were no more than .015″ at any point. I could probably have just drilled these holes when I had the spar at home on the bench. BUT now I understand things a lot better and I’m feeling OK about where the holes are and the way forward.

It is quite satisfying to have these 1/4″ pilot done. I can set the spar and wings up for the real drill out now. Despite my best efforts I still needed to make minor corrections in the drilling. There is no perfect flat surface for the jig although another week and I could have devised something.

That said the holes are in a good place, I drilled up from 1/16″ so the drill part was easy through the metal. Once I got to my long 3/8 bit it was much easier to see if I was parallel to the spar and by the time I did the 1/4″ its pretty close.

I might open up the outside holes which are just guides, make a metal 1/4″ guide and when my metal cutting spotface drills arrive from the USA I’ll use these long shafts to get my drill really square to the job and bondo the guides onto the outside of the spar. With the inside hole pretty good, I think this might give me the square hole (if you pardon the term) that I want.

Next job is to really secure the spar and wing combination for the 5/8″ drill out.

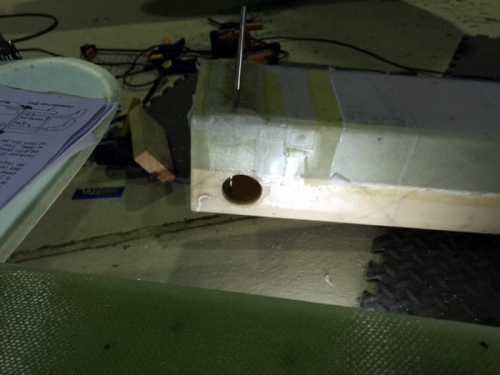

Drilling jig in position

Nice and easy to see

I’m through!