| Date: 03-10-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 14-3 |

The plans call out for wooden inserts of spruce. I beg to differ. After seeing what normally torqued AN4 bolts do to spruce I went for a harder timber.

I was thinking mountain ash (hardwood) but found some nice Silky Oak that I had used many years ago to make an electric solid body mandolin. So while heavier than spruce, these pieces are a part of the engine mounting and need to be uncrushable.

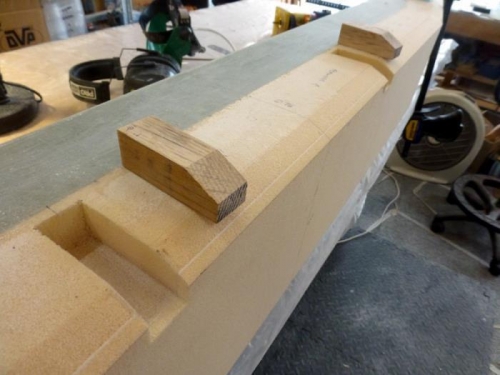

Once the timber was selected I made up four 3″ X 1 X 1 pieces the routed out slots for them as you can see in the first pic. They go to the top and bottom but I did two at a time over two days. They are glued in with micro and I used weights to ensure a solid fit. I should mention that while I used micro on the sides, I used pure epoxy on the base as this is down to the inner glass layup. I could have used wet flox, but it was a nice tight fit.

Bit of a clean up the next day and then the second lot were finished. Now all four are in position and its on to the next job. Quite a contrast to the many hours involved in doing the spar caps.

Inserts ready to go

A little weight for the cure

Flush inserts