| Date: 10-27-2018 | |

| Number of Hours: 10 | |

| Manual Reference: 23-2 |

The next step is to create a secondary cowl lip on the cowl lip below. This is to make camloc fastening possible. I’ll thank myself for going the extra mile when its finished.

Here’s the first lip with the cowls removed, which of course took a while. Those gaps between the spar lip and the turtleback lip are for later treatment.

Next up was to trim away where the lip will be. In other words, this area needs to butt against the new lips on the fuselage side.

Once trimmed I added release tape.

Now the cowl needs to be hot glued into place from the top.

The sides were relatively easy to get in position but the rest of the cowl truly has a mind of its own like a living thing. I think it will work out OK. The perfect lines I’d like to see and everything matching up…well this is why I work in fiberglass rather than metal. I’m not so perfect myself.

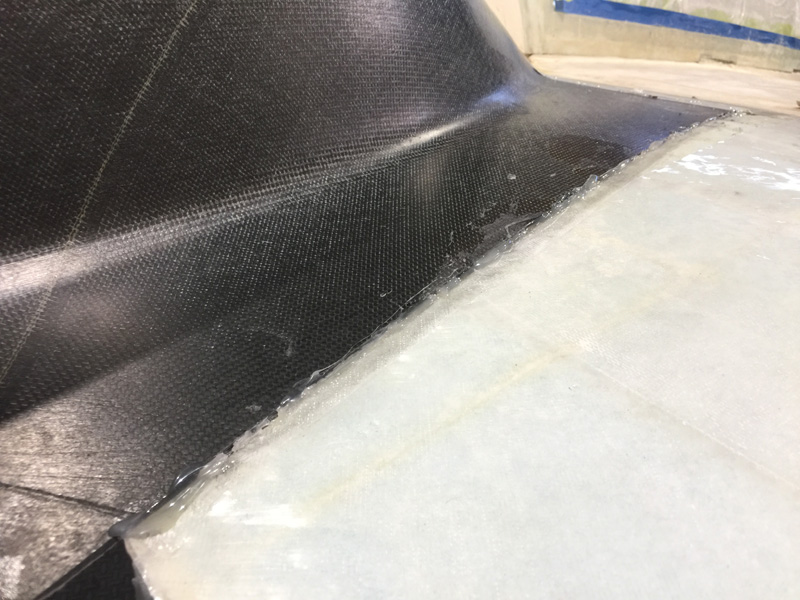

Where you see the bright light is where another 5 ply of glass goes.

These plies overlap the newly created lip and onto the bottom of the cowl. I found taking before and after the layup photos looked exactly the same. So you can guess if these are before or after. It was a huge job to do this from morning until after dark.

These cowls, not to disappoint, have an additional challenge. The area next to the canopy has a huge gap each side where I need to make fairings. I think this whole cowl attach thing need to be repeated there so I can put a fastener on it and get a good seal.