| Date: 10-25-2018 | |

| Number of Hours: 14 | |

| Manual Reference: 23-2 |

Yesterday and today I made more progress. Finishing up quite late tonight in the hangar.

It took a while to trim the cowl to a reasonable fit at the turtleback.

I clecoed this in place and spent a while getting the sides trimmed to fit.

The very helpful hanger owner gave me a propeller back plate to use as a former to keep the cowl straight. A good thing too as it always looked a bit off due to a slight angle in the carbon pattern. This ensures I’m reasonably centered.

I tried cutting the glass out for the initial lip layups on my improvised bench but ended up on the floor after a good clean up as a better place to lay it all out.

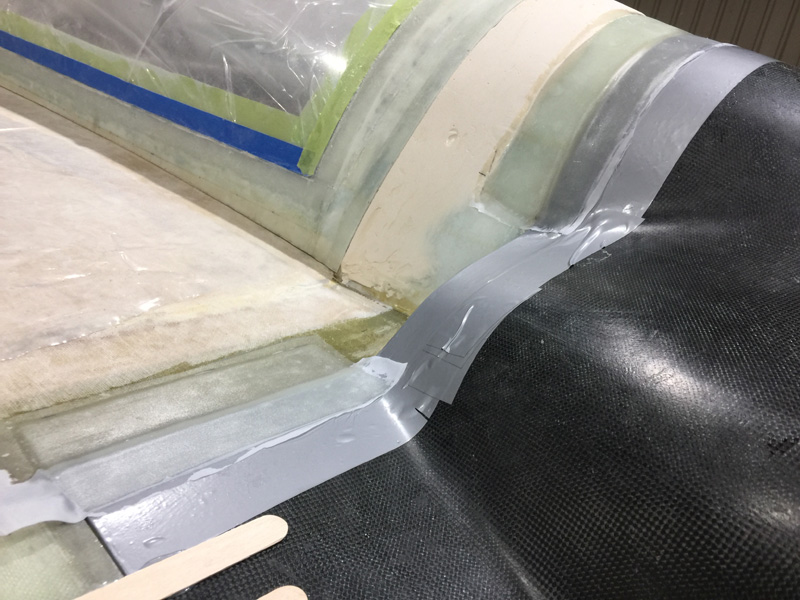

With lots of release tape I started securing the cowl.

That back plate got a clamp and later some hot glue.

Plenty of hot glues sticks positioned the sides pretty well flush with the tops of the wings.

Underneath more hot glue and then the clecos could be removed.

I’ve done 5 plies of BID for the lip per plans in thickness.

The cowl angle is pretty good now.

Here we are laid up and peel plied.

I’m not sure yet how I’ll deal with that gaping hole. Yes it will get a fairing. Maybe just a lip for the cowl to fit into.

At the wings I’ve also laid out a lip upside down. It stuck there pretty well.

Here again is the cowl line. It will need quite a bit of filler just at the top. The sides may be easier to blend. The very top forward edge of the cowl seems to go a bit flat for a few inches. This is just how it came and I may fix it to be a perfect line.