The taxi testing process

Taxi Tests 4 – Not Good

| Date: 11-26-2024 | |

| Number of Hours: 0 | |

| Manual Reference: |

This is taxi run #11 I think, who’s counting anyway? I wanted to try and sort out the radio problem AND see how the cooling goes with the cowls on. I’ve just added the heat shields, the top cowl stiffening works a treat and I was expecting a good result and even start runway tests the same day. On to first flight in a week.

Not so…

Previously at low RPM, cowls off I could maintain temperatures on the ground. This is my big goal for the plane so I can sit in a queue at airports for as long as I need without shutting down the engine because it got too hot.

Yes I could then use a handheld and do a hot start as required but this is a pretty awful way to operate. Its a lot of extra pilot stress too and I’d be hot on the take-off roll when I finally got there. There may also be problems restarting the engine when it was my turn. I’d have to restart each time the queue moved too.

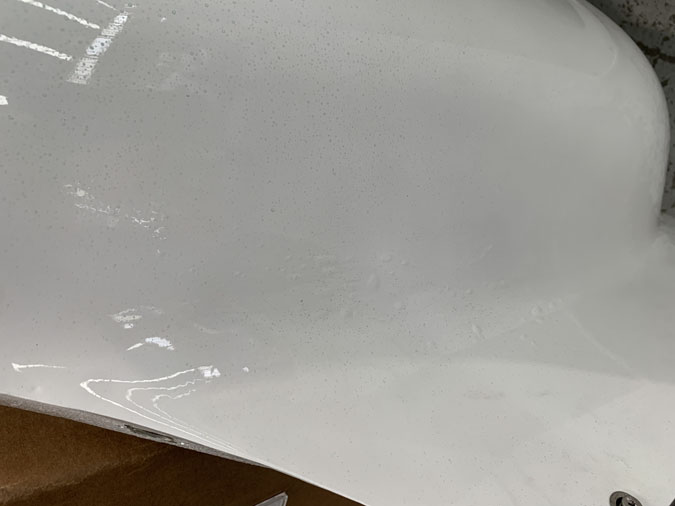

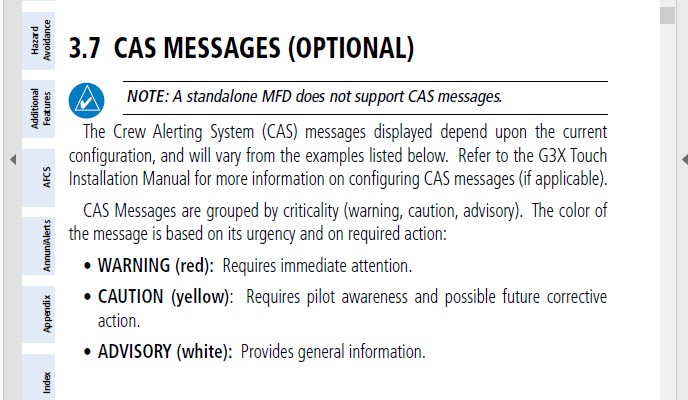

Cowls on and my cooling is an epic FAIL. Even at 860rpm the temperatures kept slowly going up. I got to 212F after the radiators although the temps before the radiators where not much better. I have three sensors for all this. I was also up to 13psi coolant pressure when I pulled the plug and taxied back to the hangar.

The cowls were REALLY hot to the touch when I got out. Oh and no joy on the radio problem either. Anyway that puts a big stopper on my imminent first flight. I could go ahead and fly, but then what? It’s going to be far easier to solve this problem at Moorabbin that relocating to Leongatha where resources are only what I bring in the car and things like wiring would not happen easily. Given it just doesn’t seen to cool down quickly after the engine is stopped that idea of shutting down and restarting in a queue is not really viable either.

What to do? How to fix this ground cooling problem?

Get data. I need to do a lot of testing, timing how long it takes to get hot. First cowls off, then bottom cowl on with top cowl off then bottom on top cowl off. I need the numbers. I am expecting to find it OK bottom on, that would tell me that I need a huge vent in the top cowl. What I expect might not be what the data tells me.

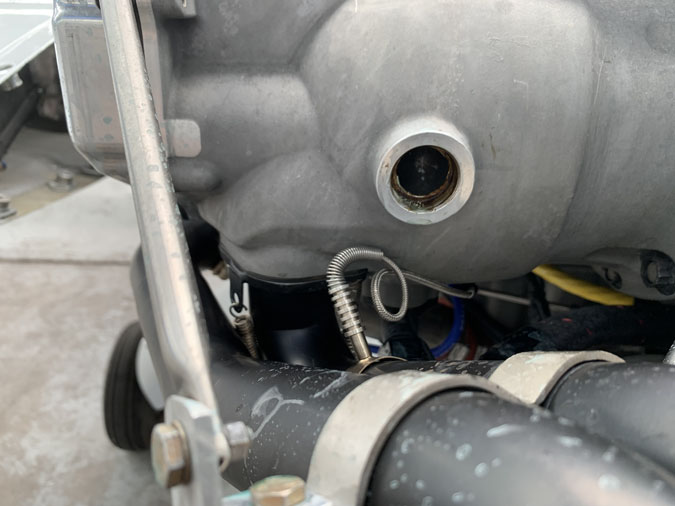

Get data. Fans do not work properly without shrouds. Testing last night with bits of paper revealed that air is getting pulled in from the HOT side into the fan at the sides. As a quick and dirty test I need to block off the areas around the fans at the back of the radiators and see if this improves my test numbers. If it does, I am looking to add a third fan and test this too.

If that works I have an idea for louvers at the back of the fans which are closed on the ground but open in flight. This is a common automotive practice that someone smarter than me pointed out. So if the blocking off thing works I have a plan to make it useable.

If all this fails, what comes next is ugly. The tests should tell me if I need to vent just the top cowl or both top and bottom. How big to make the vents? How to I find out without cutting up the existing ones and cutting too little or too much or in the wrong places??

Yes I’m going to have to make a test cowl or even several cowls. I’d use the existing ones as a positive plug (mould). No small task. It doesn’t have to be flight worthy, just strong enough to sit in place while I taxi around slowly. It will probably have to be three ply of carbon too so I can get it to hold shape as I cut bits out. What comes off could be re-joined as I get the shape and size worked out.

If big vents work I am going to have to have doors that open with linear actuators and they don’t like heat at all. Remotely locating one would be very challenging and if its via cable it may need to be a push pull. A real can of worms, maybe something like the gear doors that spring open and are then held closed. Essentially I’m looking at cowl flaps that some GA planes have as standard. Maybe I can rig up a manual cable and set it so the airflow will tend to keep it closed.

Secondary to this is to get more control over the water pumps and fans. At the moment it is automated so the fans and pump at full power kick in at 170F or whatever I set it at. I do have an aux pump on a manual switch. However at the moment it is only circulating coolant that has not been cooled well at the radiators so it does nothing much at all. That’s the blocking off thing I need to look at. The other thing is to may have the third fan also just an on/off so I can at least get the fan and pumps going early if I need to. It would be on me to get them off once I’m in flight. This might help stop the heat build-up that seems hard to get rid off.

It looks like I’m not flying this year after all. That leaves questions on my pilot currency for first flight as I want to let the old plane go by the end of the year. I have decisions to make in a week or two.