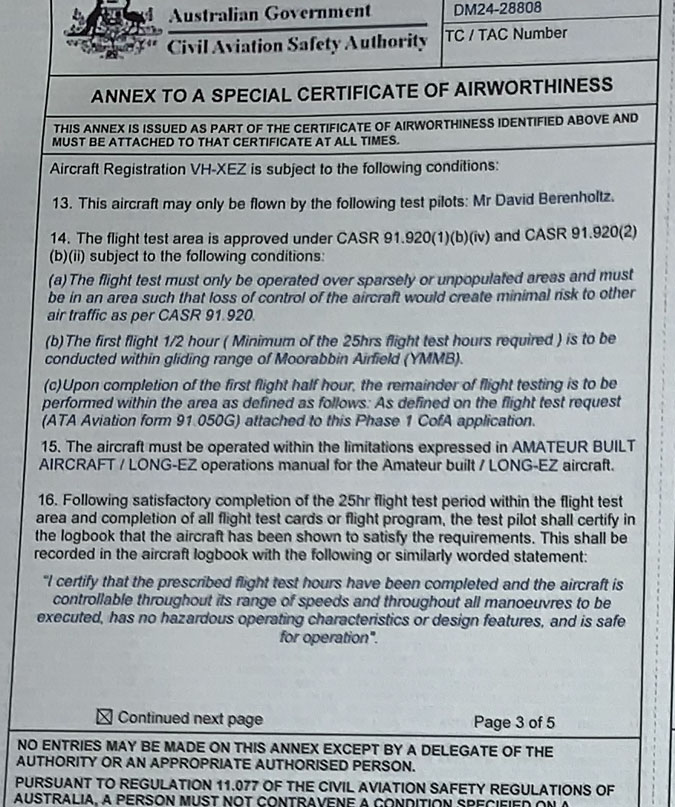

| Date: 04-16-2025 | |

| Number of Hours: 35 | |

| Manual Reference: 25 |

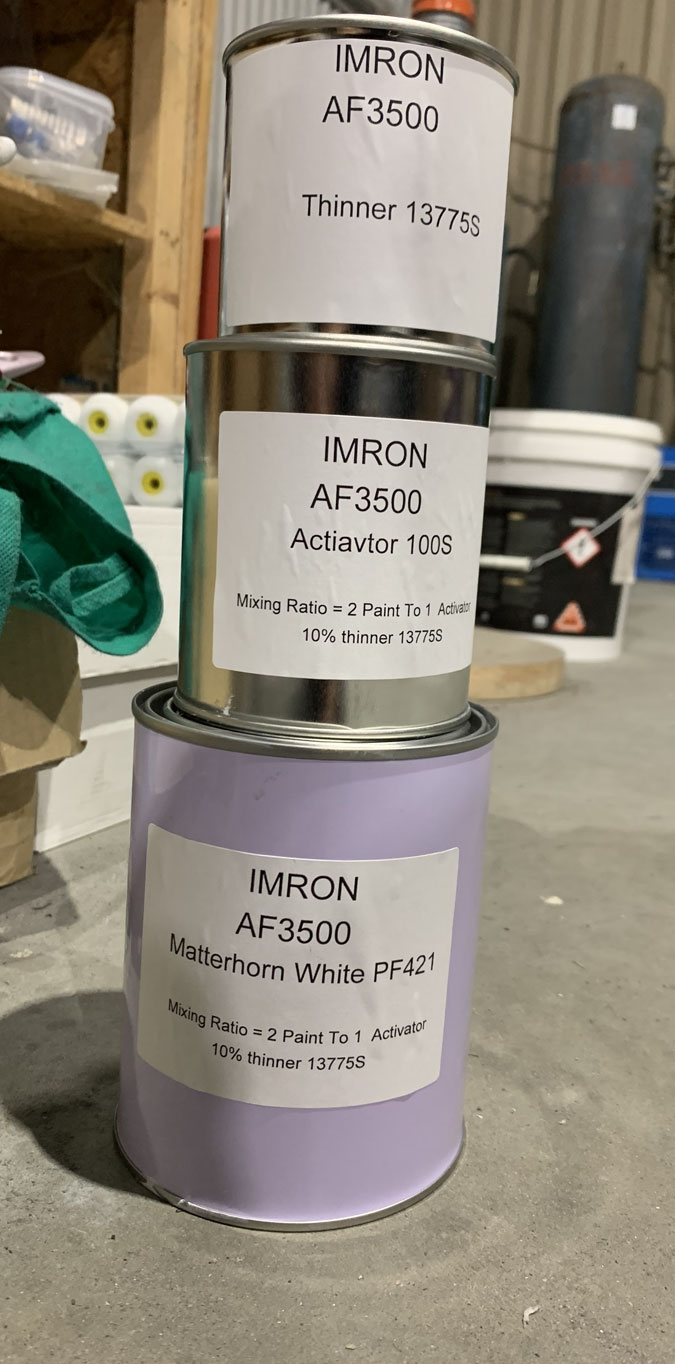

Time to repaint the cowls…again. They were done beautifully the first time. Then I had to lose a welsh plug and they were heat damaged during taxi testing. Next up I decided I had to add four huge flaps for ground cooling. That make a bit of a mess. Then I did a taxi test with insufficient heat shielding, that further cooked a few more bits.

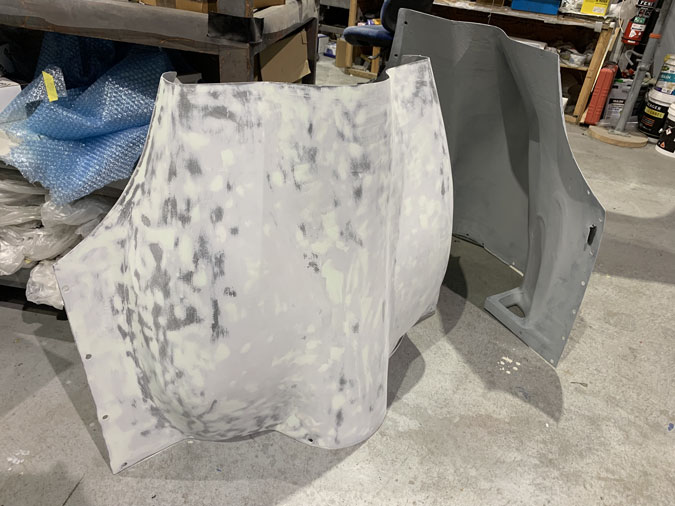

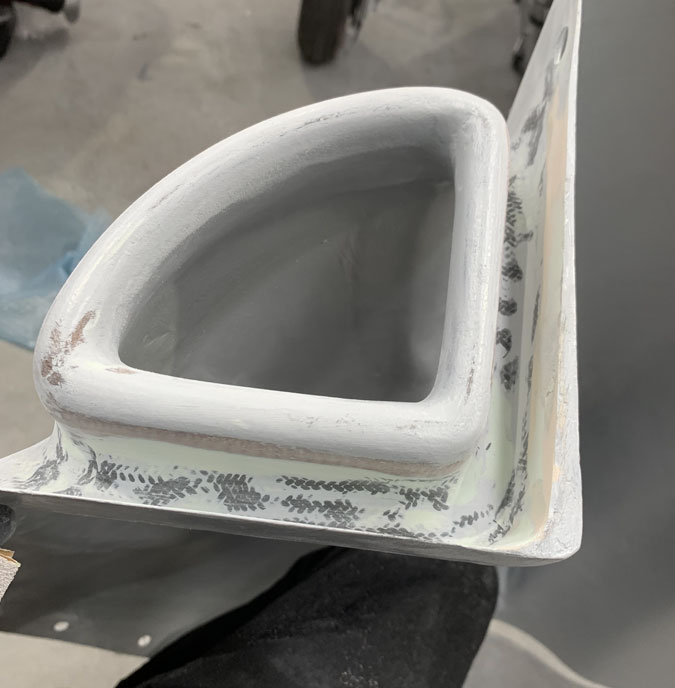

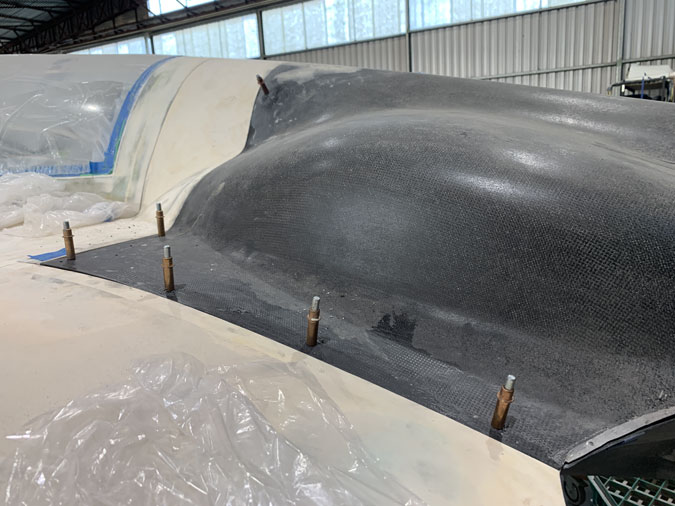

The first job was to address all four flaps and improve the ‘intersections’ where they met the cowl openings.

This was a two step process where I would work on the cowl side with filler and get the intersections right and then the flap side with the same thing.

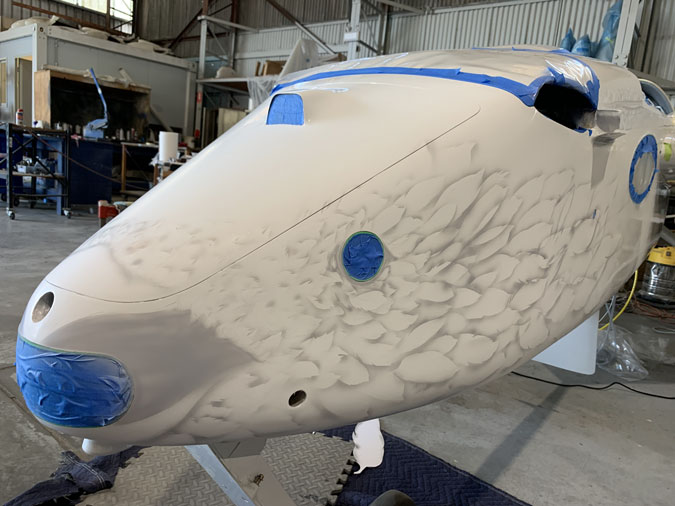

Of course this meant a lot of sanding. I little with the air driven tool but plenty by hand too.

I did a lot more sanding than you can see here. I spent days getting them ready for paint.

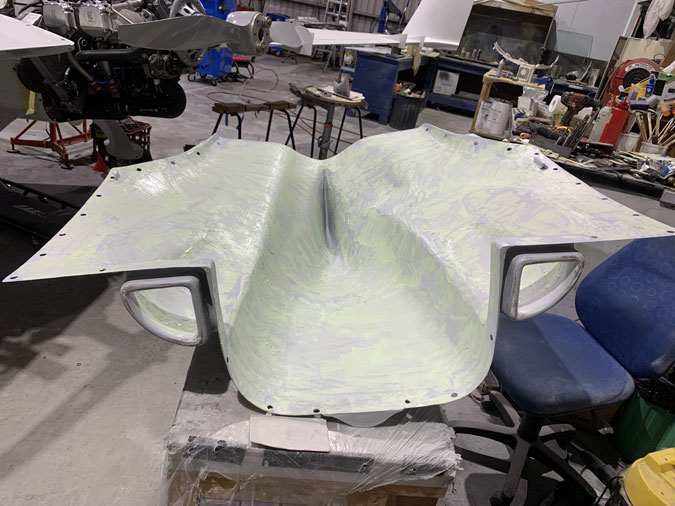

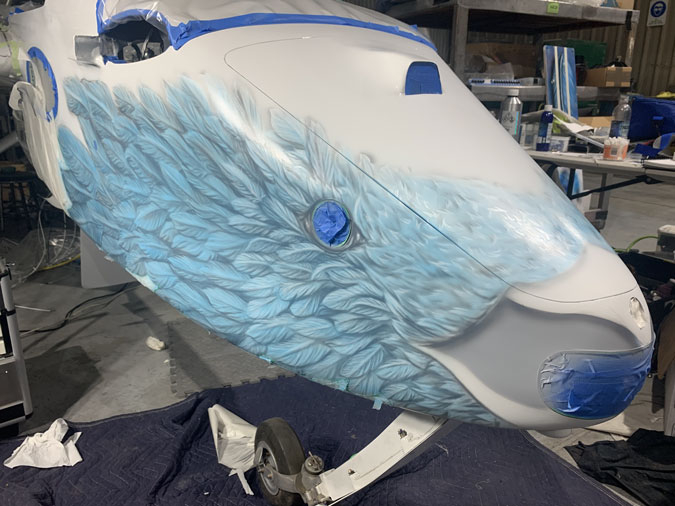

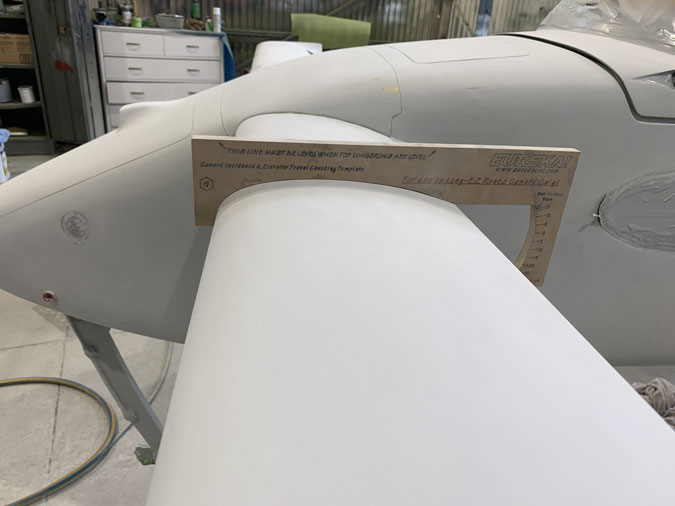

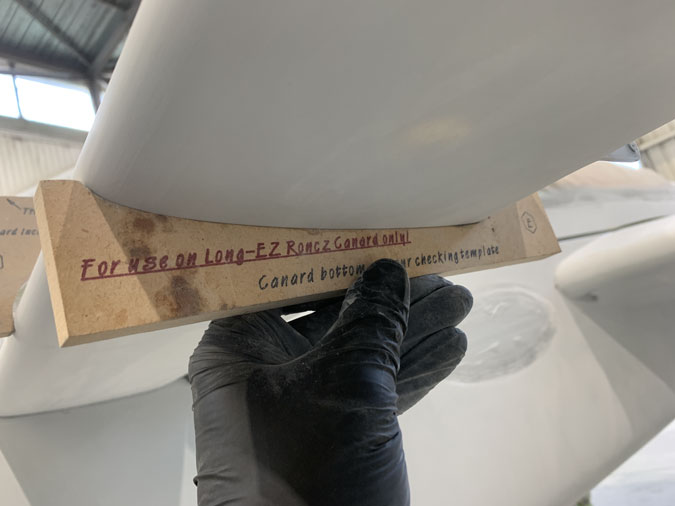

Of course my efforts were not enough. Once the first lot of primer went on, the paint started to bubble. The heat damage must have really upset the lower layers. So my expert, Jamie, pictured here, spent 51 hours getting it right. That was with a lot of sanding and filling before the primer was again introduced. Then more sanding. She is even fussier than me. I can put that work in but I don’t get the same results. Some people only have one standard.

Perfection is the enemy of good enough and no prisoners were taken on this job.

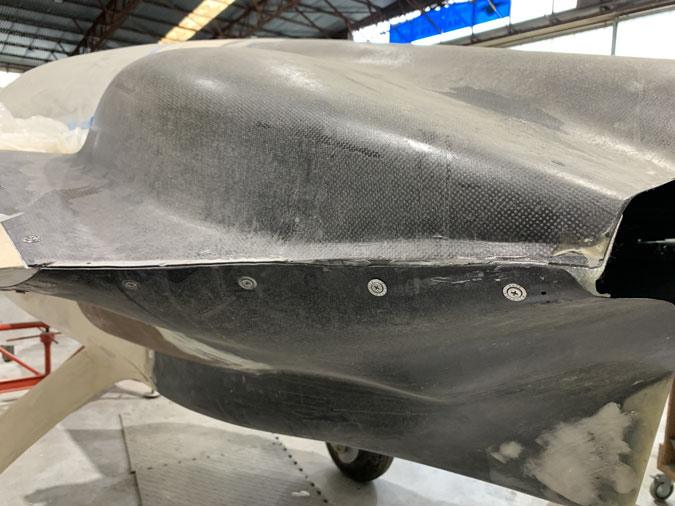

They really are as good as you will see anywhere now.

No polishing, this is straight off the gun.

After the cowls came back I had quite the task to reinstall the hardware. It was three long days. All the edges needed to be addressed where the cowls close as well given a little paint build-up had slightly effected the flap closing.

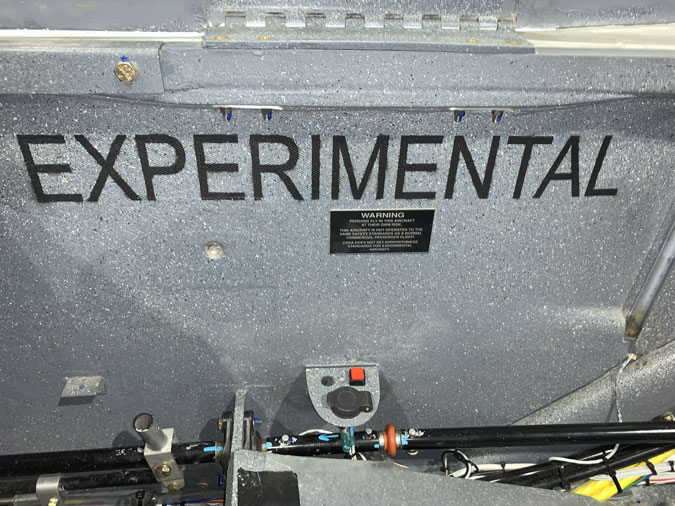

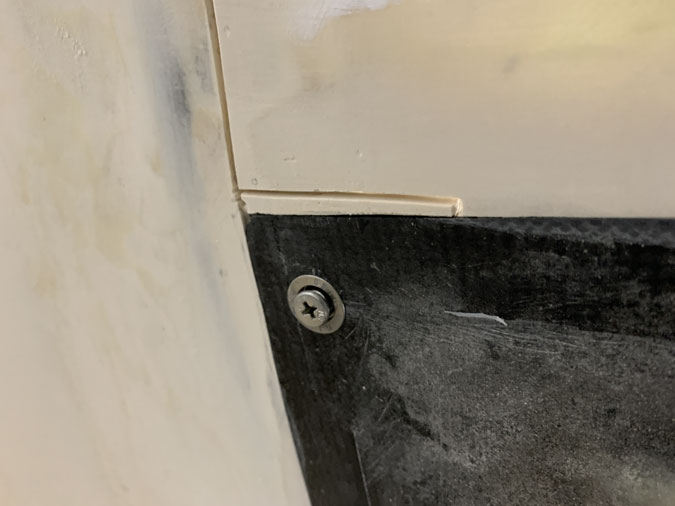

This might give some idea of the quality of the paint work. Yes I know I used a lot of fasteners. There are a few things I would do differently next time. One would be to take the hardpoints all the way to the skin rather than leave a little foam. I was worried about all the extra weight but you can see slight depressions where I have to tighten things up in some places.

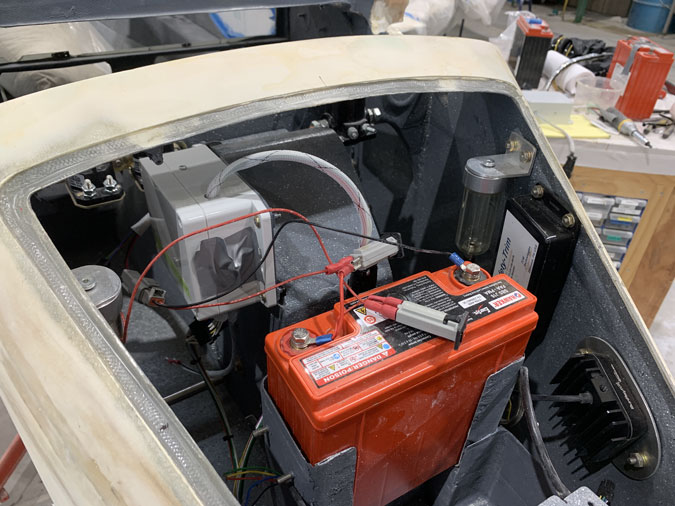

The insides were also painted again, not with the super high quality and insanely expensive paint, but a good two pack white. This is mainly so where oil and grime builds up I can see where leaks might be and do a good clean up. This time I was meticulous about adding heat shielding afterwards where the exhaust pipes are near the cowl surface. The bottom cowls had a similar treatment. Even the actuators have full heat shielding to protect the mechanisms.

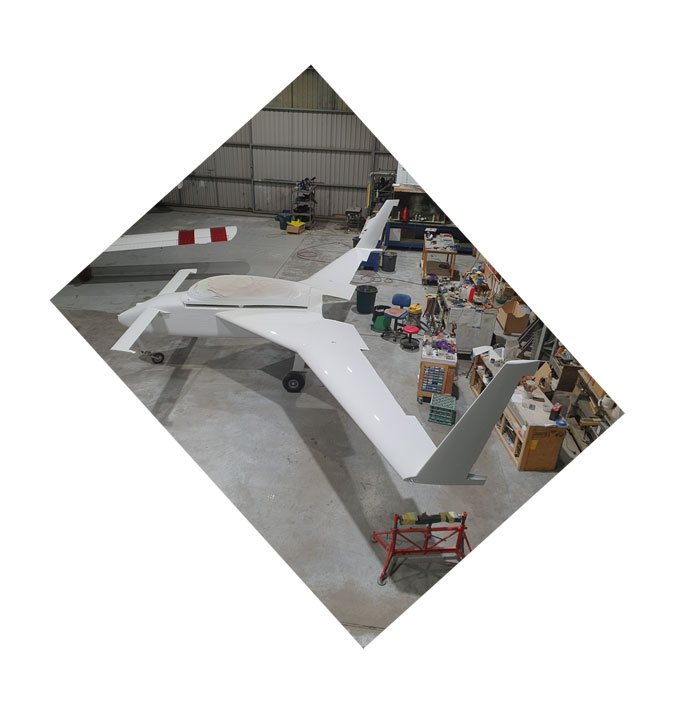

An unrelated shot, but I did want a record of this. People say the Long-EZ is a small airplane. The wing span is 26’2″ while an old Piper Cherokee is 30′. Just under a four foot difference, a relevant fact when you need hangar space.

The top cowl is finally on.

Both cowls and the baggage pods are now installed. This shot was a couple of days after the first flight. The second test flight had the pods on.

Finally an innovation I stole from James Redmon’s Berkut build. There are some great mods on his pages.

Yes, its not related to the cowls, just one of so many little things I’ve been doing lately that don’t get a mention.