| Date: 03-06-2019 | |

| Number of Hours: 5 | |

| Manual Reference: no ref |

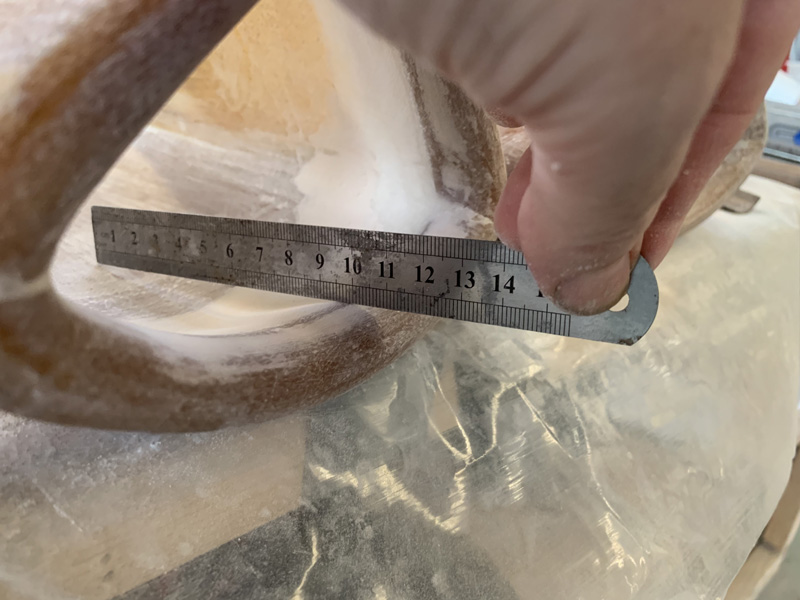

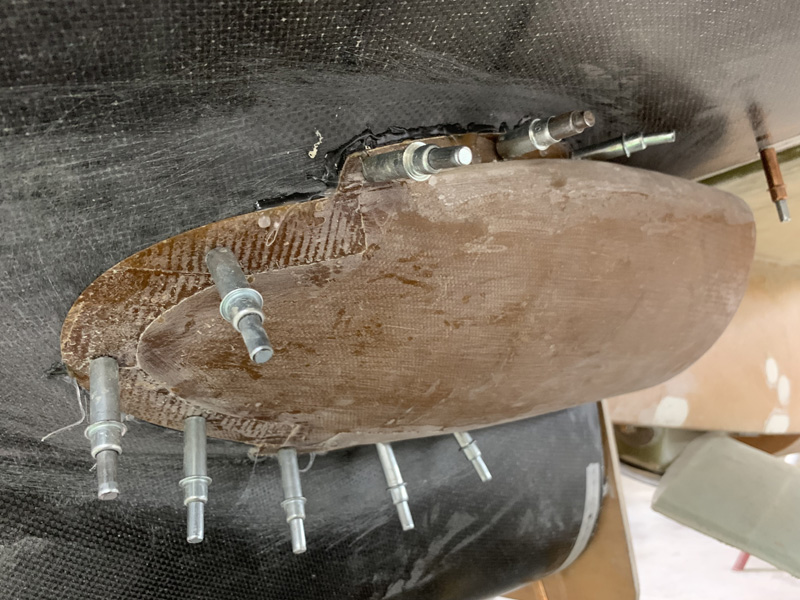

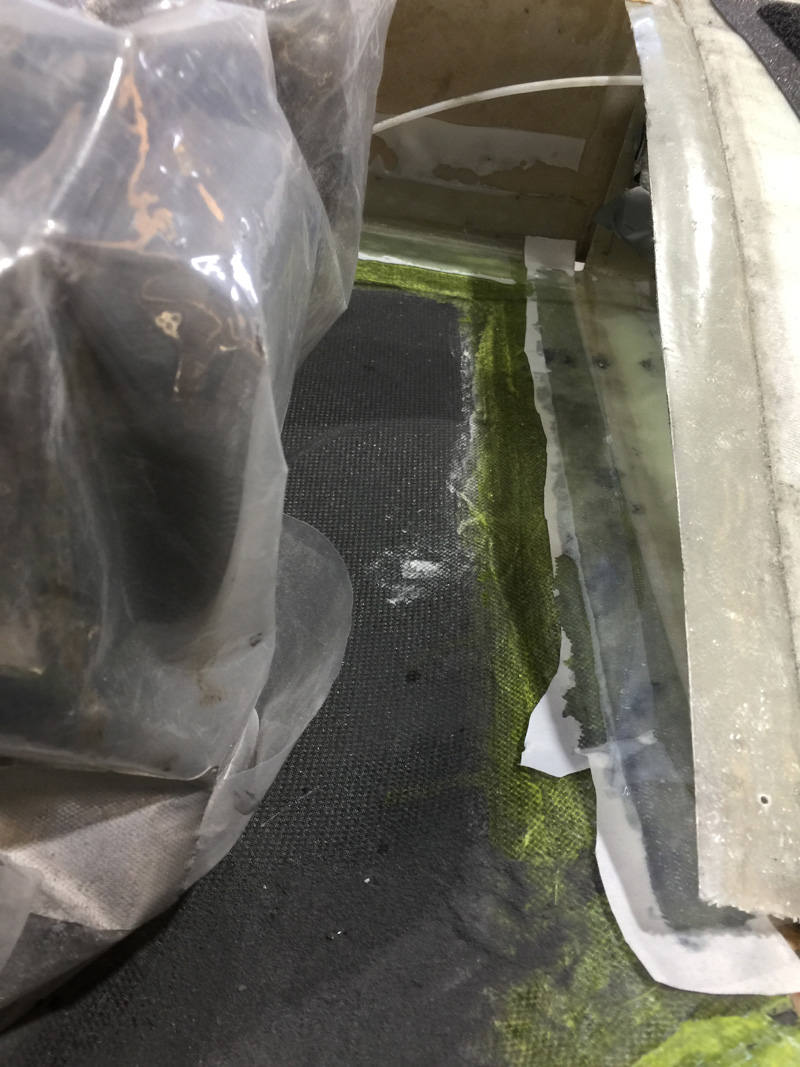

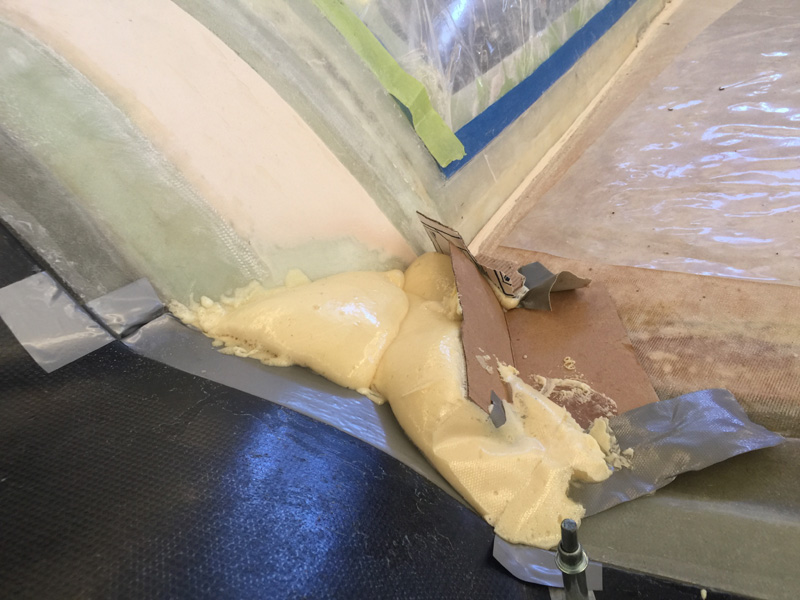

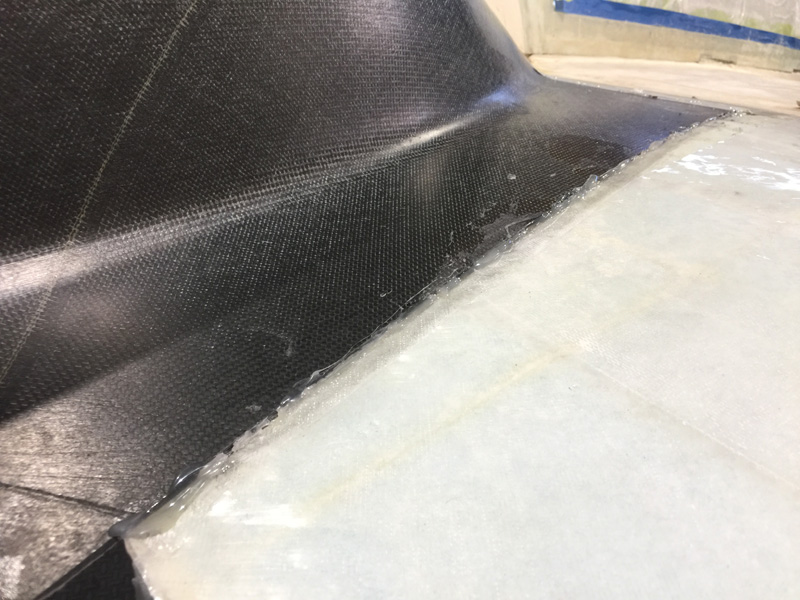

While the armpits were floxed in place they needed reinforcement to strengthen the edges at the joins.

I used flox with a little micro to fill the edges and then one ply of BID an inch wide on top.

The same thing on the outside and of course peel ply.

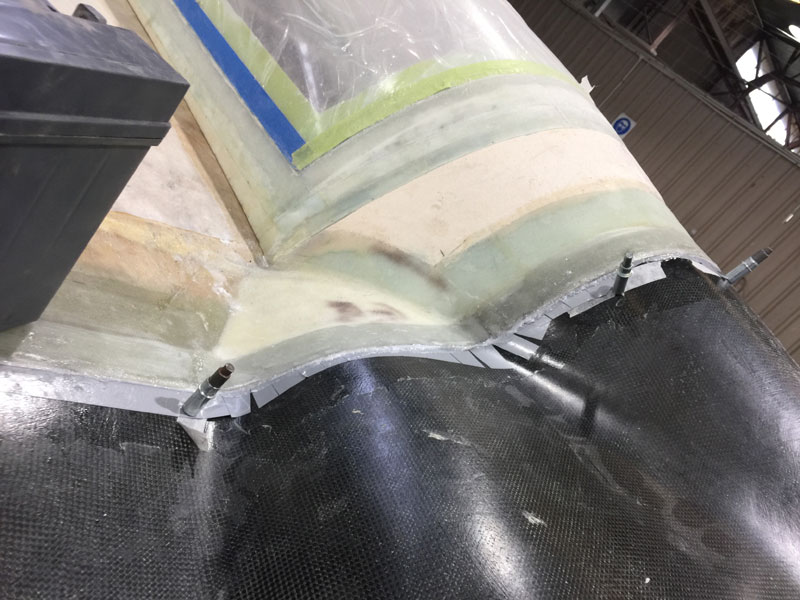

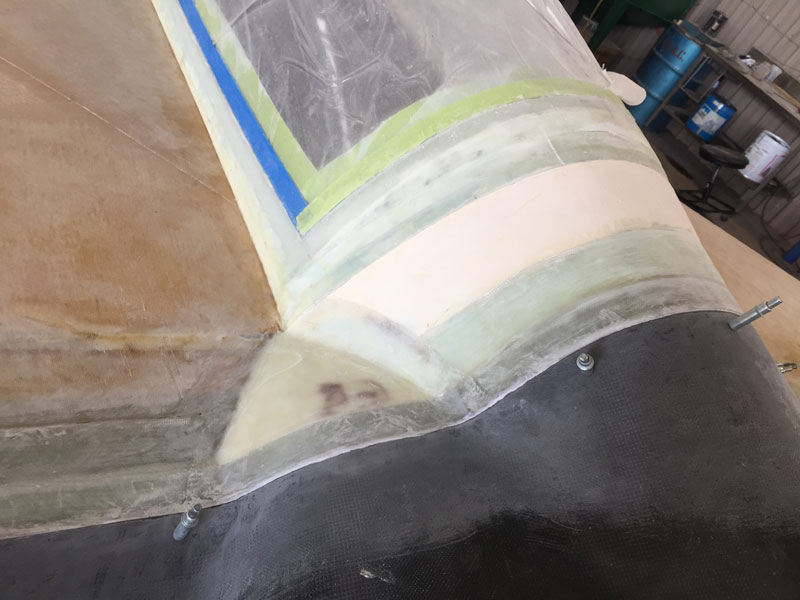

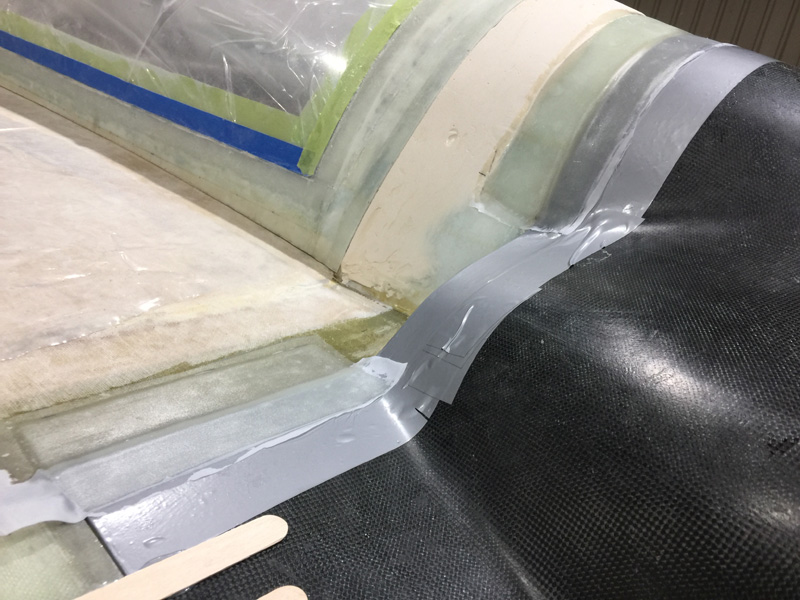

The next day I removed the peel ply and sanded. The corners will need work later but its close.

The same treatment on the inside. I’ll have it super smooth after the baffle work. Its pretty good for now.

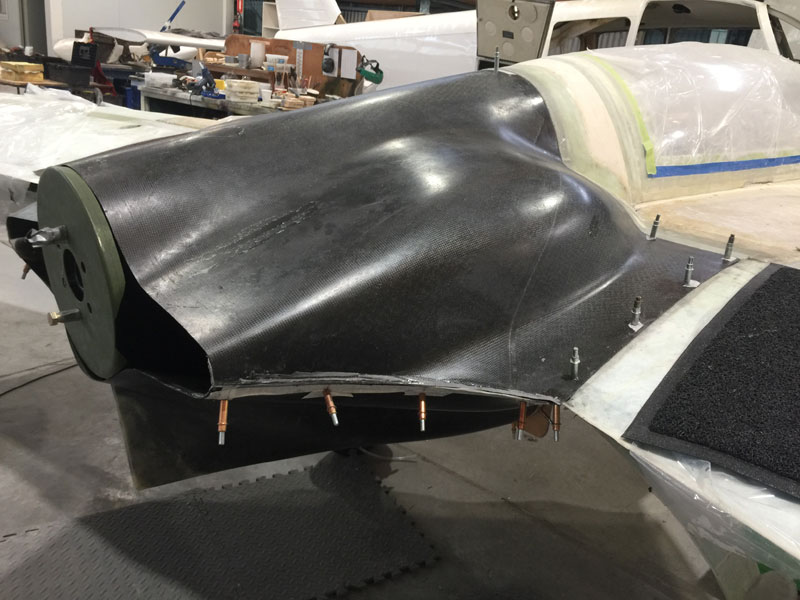

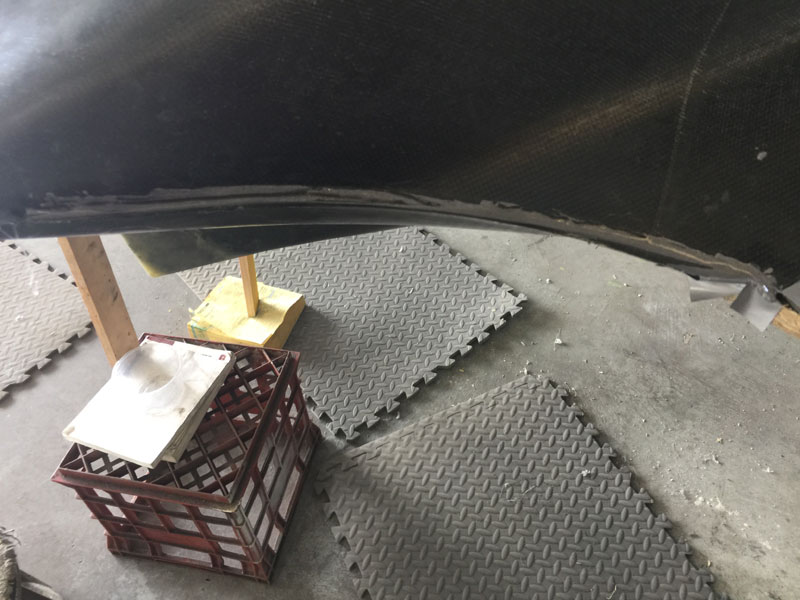

Given the fuselage curves toward the rear I can see the value of the scoops stepping out that 0.75″from the edges. There will be a bit more work later the blend the sides with the cowls. I’ll probably do that when the plane is inverted. For now lets call the scoops good.