| Date: 09-29-2015 | |

| Number of Hours: 10 | |

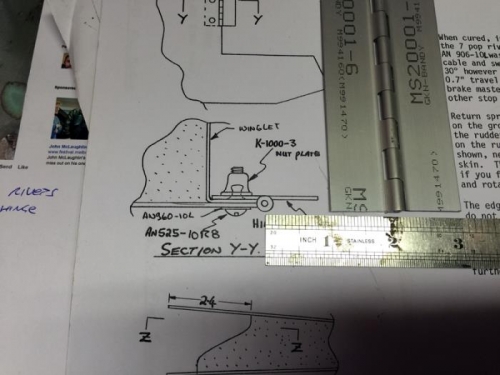

| Manual Reference: HP Rudder R1 |

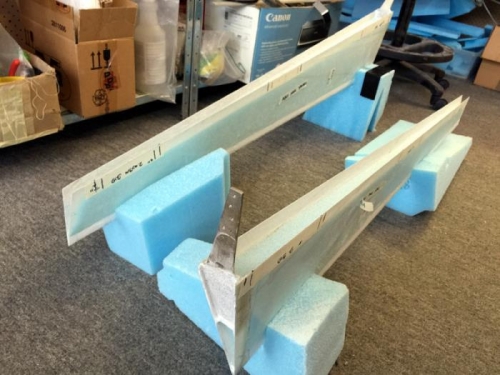

Yes I though today would be a short one. Wrong again. I just had a feeling about the hinge alignment and tried a different straight edge. Hmmmm not so in line as I though. In fact I tried lots of pieces of aluminium angle and they didn’t match my old heavy metal straight edge… which is not long enough for this job. I eventually went with some box section aluminium as you see in pic 1. Even this was straight one side and a little out the other.

I have this idea that a straight hinge line will mean less wear from rudder movement. Good thing I hadn’t drilled my holes out to the final rivet size yet. I was still two drill increments under. Having done this setup a few times I had it really straight with a really straight straight edge and secured in place with lots of hot glue and pegs.

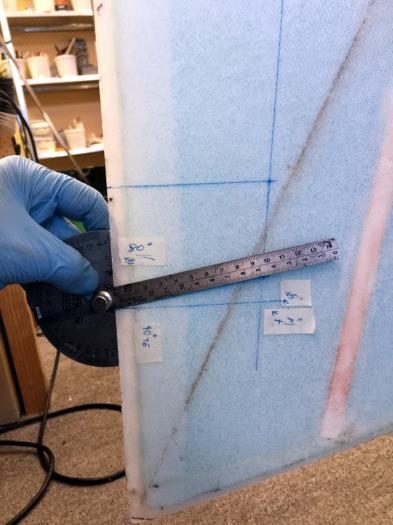

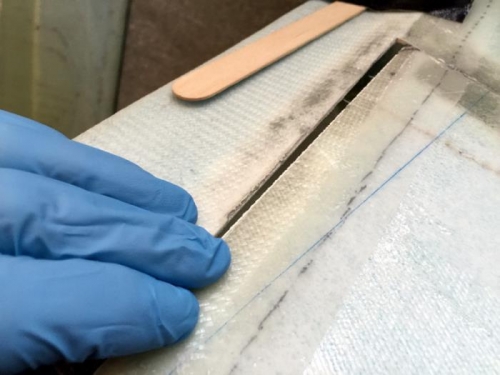

Next up was setting up the countersink tool and practicing with a few rivets until I was happy. On to drilling out the holes to #30 or 1/8″. I then cleaned up and alodined the hinges. I think they were already coated but this covered where the cuts were made and the light sanding I did. Perhaps unnecessary but no harm done. While the metal was drying I countersunk all the holes and prepped the glass.

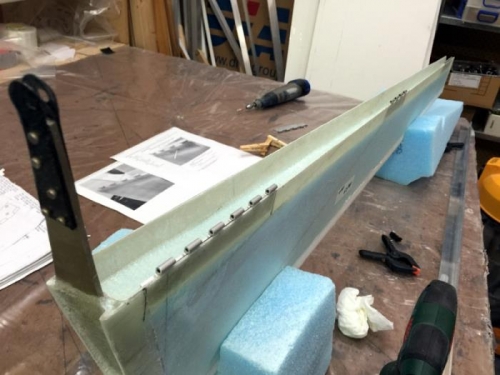

Finally I got to mix some epoxy and made some flox. Pic 2 shows how I went from clecos to rivets I checked the alignment a couple of times too and all is good. Pic 3 shows some of the rivets but all are done. I have no idea why all this has taken so long, but this tiny little step is completed. Of course we still have the other side of the hinges to install.

Really straight hinges

Flox and clicos

Hinges on the rudder side

\

\