| Date: 11-29-2015 | |

| Number of Hours: 20 | |

| Manual Reference: 19-8 |

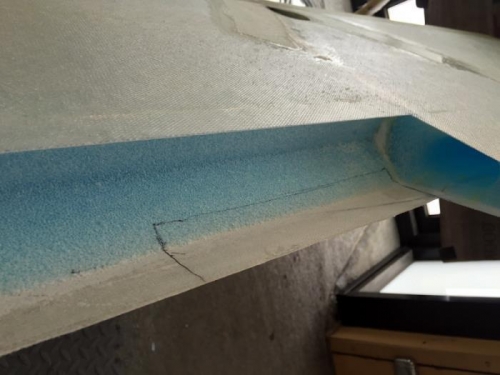

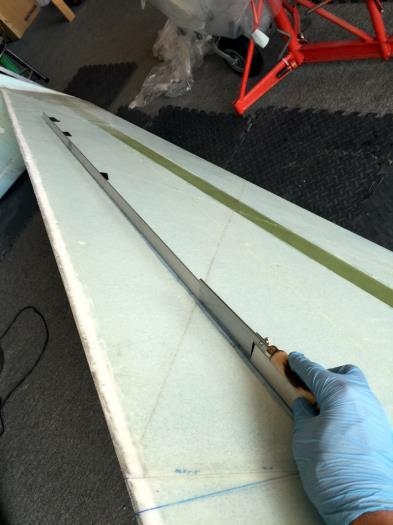

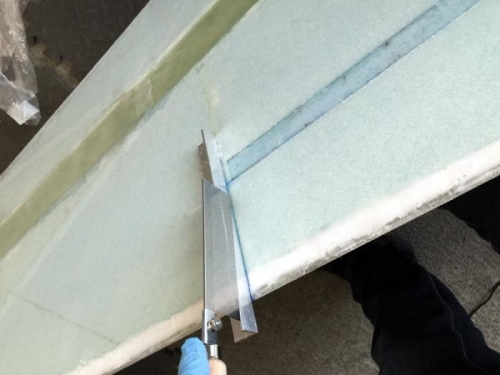

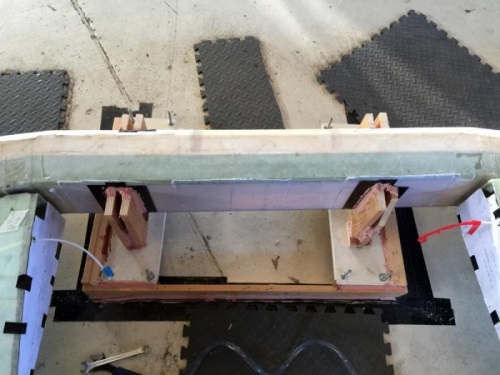

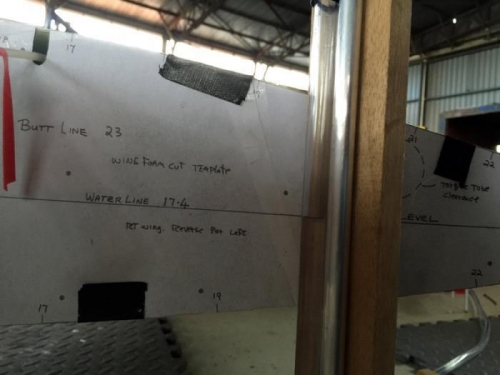

This is a simple step, just cleaning off the glass areas and smoothing out the foam as required. I made sticks with the distances marked as you see in pic 1 and spent a crazy amount of time getting the glass areas clean. This is meant to be easy because we have previously layed peel ply between the foam and skin layups so it should just come away clean.

Turns out that I needed to spend hours with a sharp chisel on the areas that didn’t come under the peel ply and that stuff didn’t want to come off cleanly in some other places. Given the importance of this area I just spent the time to get it right. I was also careful to remove an extra .01″ at the hinges so I don’t have to trim them as I did the rudder hinges.

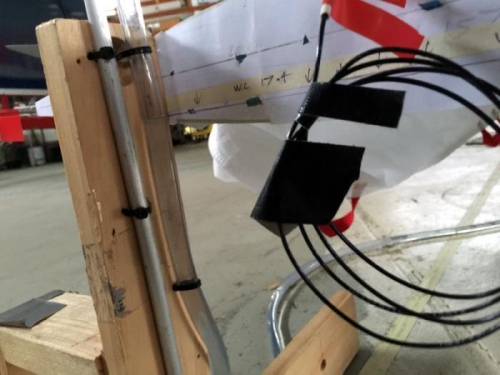

Quite some thought has gone into how to do this trough layup. I’m going to add one extra ply of carbon at the hinges and the layup itself will be on foil and in stages. I’m leaving out the inboard section at the push rod entry until after I have the hardware in place.

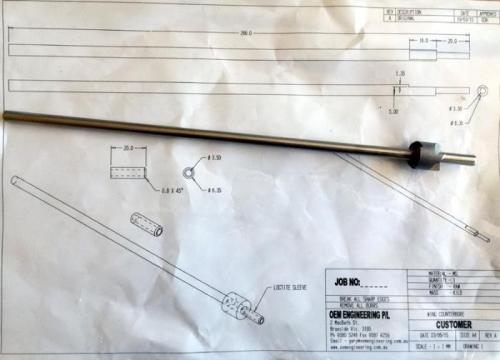

Probably another day of prep at least still to come. Meanwhile I’ve been gathering materials for the ailerons and doing a lot of weight calculations. I’ll add the results to this log later. I’ve also chased up taper pins and a matching reamer to replace some of the AN3 control bolts. No slop is the goal!

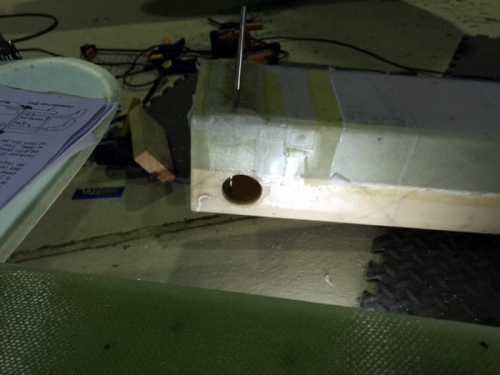

Depth check for hinges

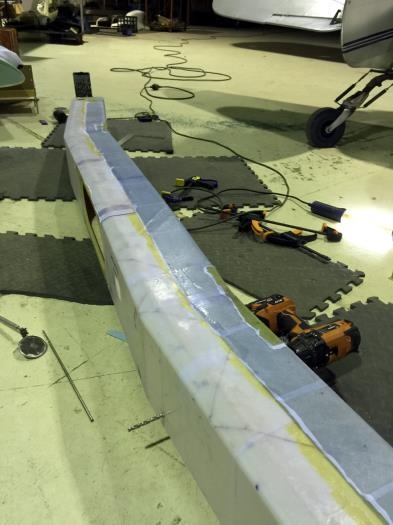

Sanded clean and marked out

Both wings now ready