| Date: 02-06-2016 | |

| Number of Hours: 10 | |

| Manual Reference: 19-9 |

Plans have the builder use a phenolic block with a hole in it to guide the aileron pushrod, CS150. I can tell you these tend to wear and can be sloppy, yep thats what I have in my already flying plane. I’m going to use a ‘plastic’ bearing instead. The part is an IGUS EFOM-16 ( from Treotham P/L in Australia )

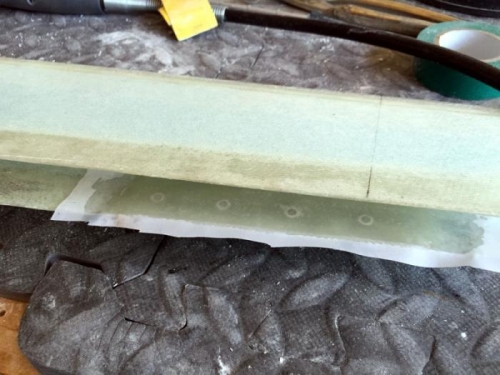

You can see these in Pic 1 where I’ve begun making a housing for them out of 2024T3 .063″ I made a friction fit, partly because I want to index the part so it cannot move and secondly to have zero air leaking into the wing at this point.

Pic 2 shows my plates made up with nutplates, alodined and ready to fit. Just over an ounce for the two. You can see a piece of tube through one of the bearings. I’ve had this machined at one end to fit the pushrod and the other end is a metric size as this size IGUS thing insists on a different measuring system to the rest of the plane.

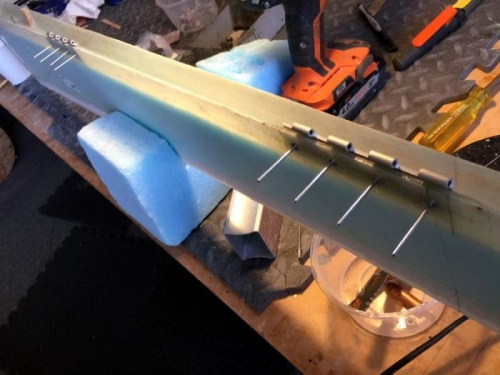

Pic 3 has the bearing holder floxed in place. I drilled 3 tiny holes so I could pin it while the epoxy sets. The bolts and greased up so the nut plates don’t fill with flox. The plates are not perfectly shaped visually but they do fit nicely.

IGUS fitting

Shaped bearing holder

Floxing in place