| Date: 11-01-2021 | |

| Number of Hours: 10 | |

| Manual Reference: |

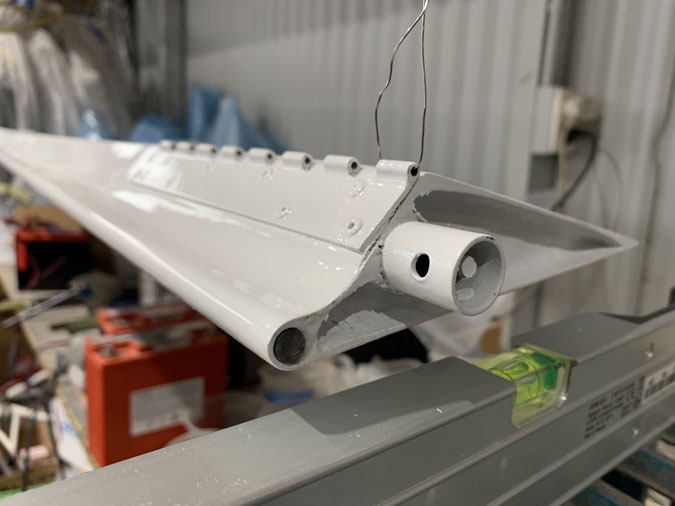

The ailerons are back in the wings. Maybe for the last time.

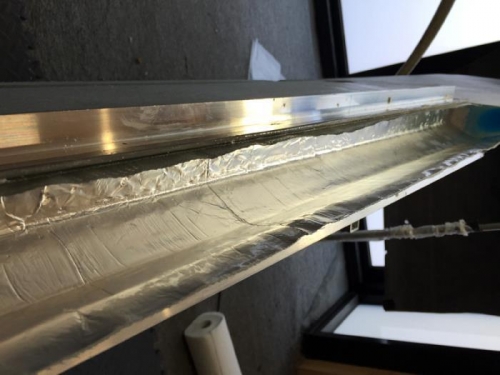

Some time ago I prepped the long pushrods with primer and topcoat. Not my best painting but I have protected the aluminium and those rods are not on show. I do like to do my best when I can noting…

Voltaire said, “The best is the enemy of the good.” Confucius said, “Better a diamond with a flaw than a pebble without.” And, of course, there’s Shakespeare: “Striving to better, oft we mar what’s well.”

Did I mention the over two month wait for special liner for the hinges after I ran out? Then many hours putting them in. Please pretend you can see them.

While the ailerons had been on pre paint, after paint it was a problem. I had to sand carefully for some hours to get it all to fit again.

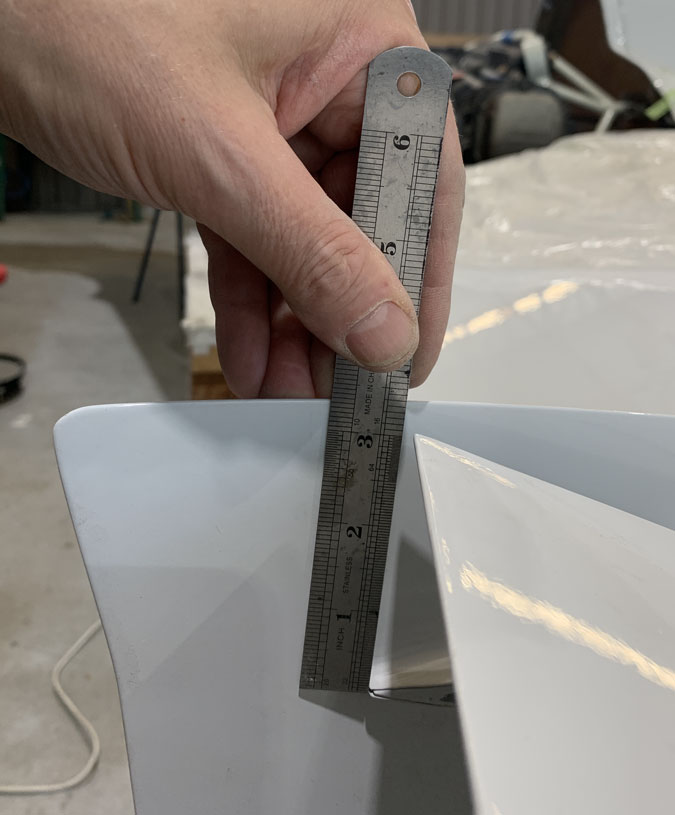

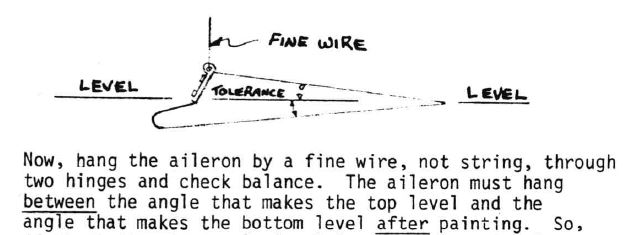

The specs are 2.1″ +-.3″ I think. Deflection in both directions inboard end. Up is easy.

Hard to see here but I made 2.2″ down on both sides. From here its just stick and pushrod adjustments to make it all correct. I needed to ensure I had the possibility of the 2.1″ all over. All is good. Roll rate for a swept wing is slow anyway and I’ve never run out of aileron on my flying LE with the 2.1″ deflection.

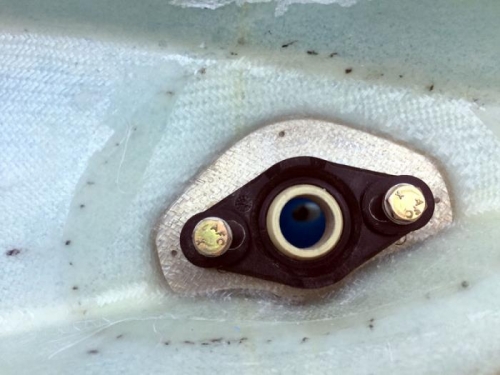

I’ve used these small metal locknuts and a thin washer and have thread showing in spec everywhere. As is my practice, once tightened for the final time I add a little blue torque seal to remind me no need to re tighten here. I just wish the seal came in a better tube, its a mess.