| Date: 11-20-2024 | |

| Number of Hours: 5 | |

| Manual Reference: no ref |

Such a simple thing. I had a padded headrest done to fit the rollover. It wasn’t as I’d hoped but I thought I’d work something out to make it more secure. The velcro wasn’t enough and it kept sliding backwards.

I found a bit of hard foam with glass on one side. The idea is to secure it to the bottom with hose clamps and that would stop the lower part of the headrest falling backwards.

I glassed the other side, then made holes in the side so where the hose clamps were bolted on that part would be reinforced with flox. I cleaned it all up, painted it, installed it. Nice job.

Epic fail. There it is on the bottom right. Looks really nice but it tended to rotate on the hose clamps backwards, not what I expected.

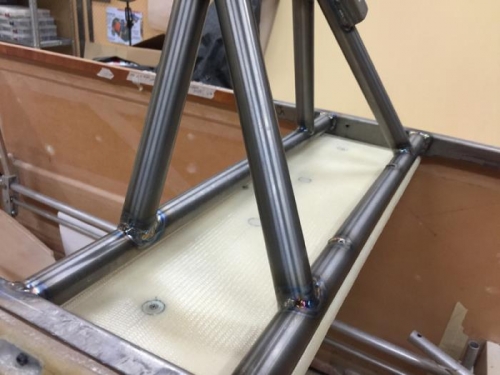

Version 2. That’s the big piece above. Yes now hose or P-Clamps top and bottom. Four of the things! At least I had found an old bit of foam with glass both sides. That’s why I keep scraps.

Looks pretty nice eh? Rock solid and weights a lot more than it should for just a headrest support BUT… As I was thinking how to do this I realised that if I store things on that tray for cockpit use I need to make sure they are secure and that they don’t fall forwards in turbulence. I needed a back board that I could velcro a nice big bag onto.

Perfect, I get a two of one here and I can now self justify the extra weight!

Headrest secured, problem solved.