| Date: 09-14-2021 | |

| Number of Hours: 20 | |

| Manual Reference: no ref |

After Paint I found that things didn’t really fit anymore and it was time to sort out some nose wheel issues too.

After some work the hell hole hatch fitted again.

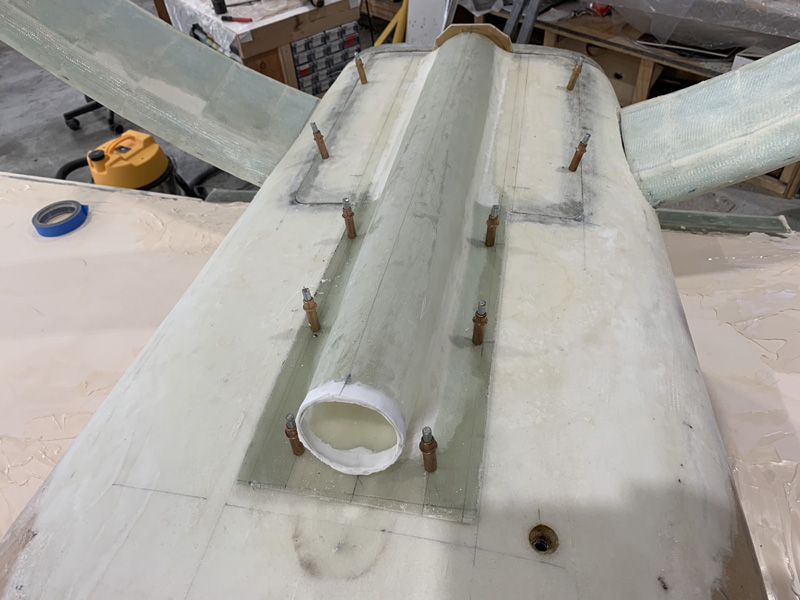

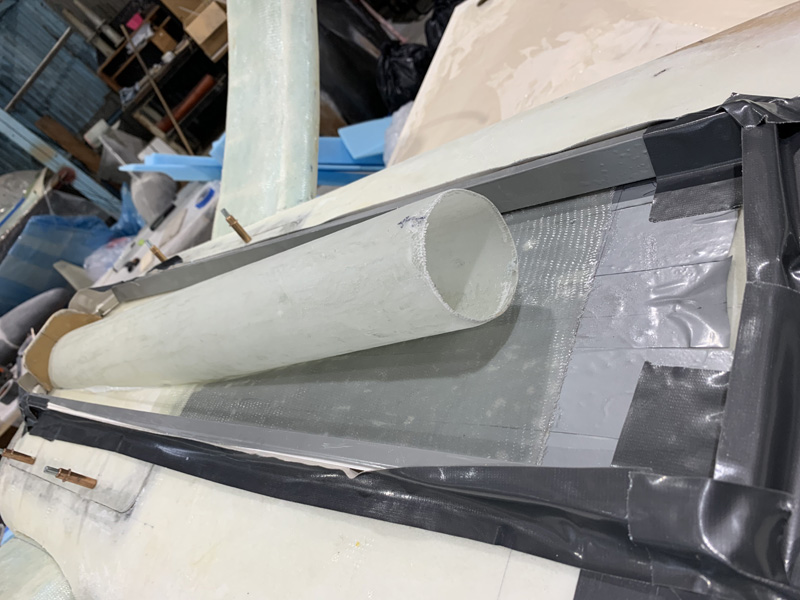

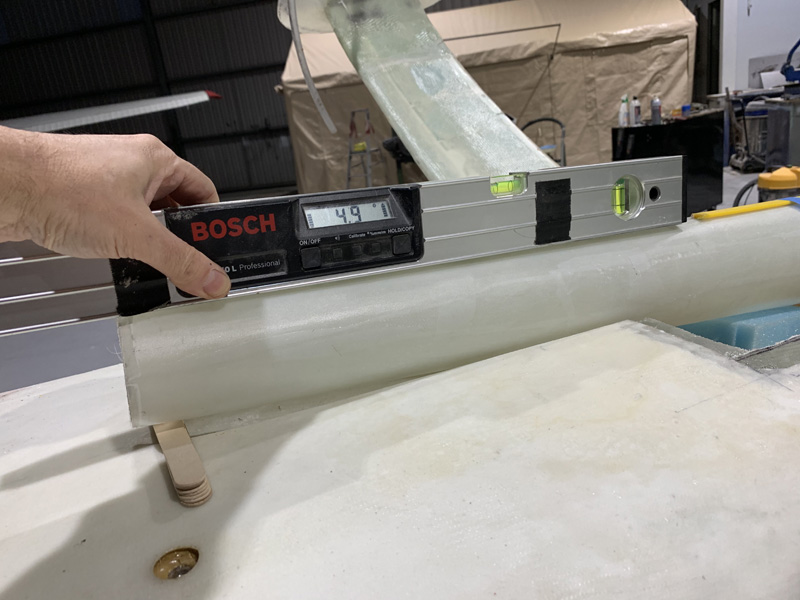

This RAM air scoop is another experimental modification that I hope pays off.

A lot of careful sanding got the paint boarders back in the ball park.

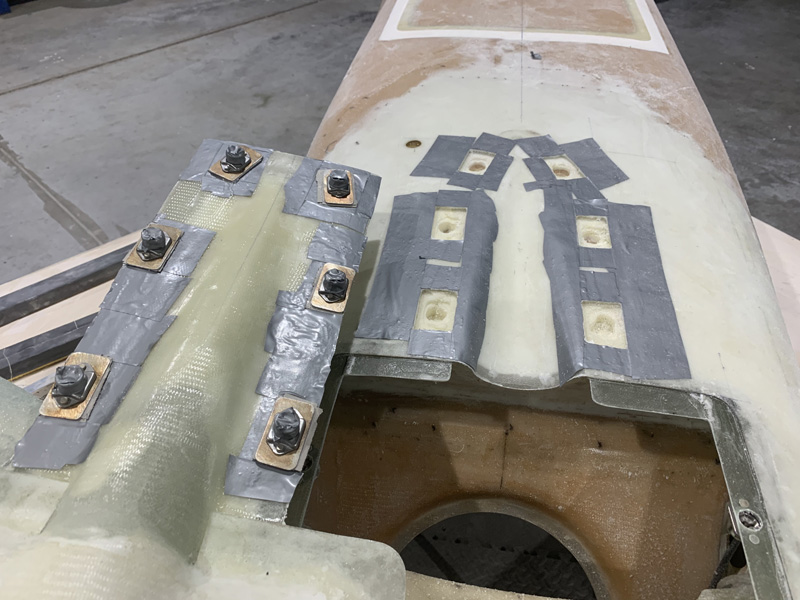

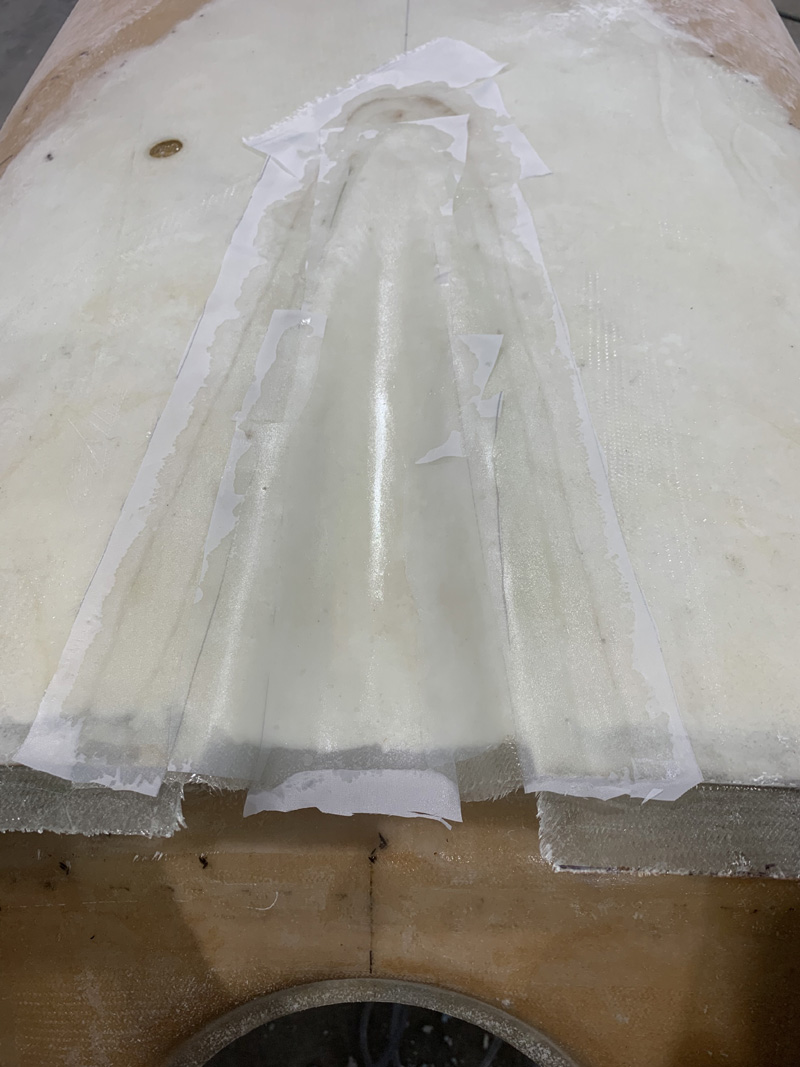

The pants look good if you photograph from the best angles. These took quite a bit of careful sanding to make them fit again too.

They do look good.

A reasonable fit and the lines are nice.

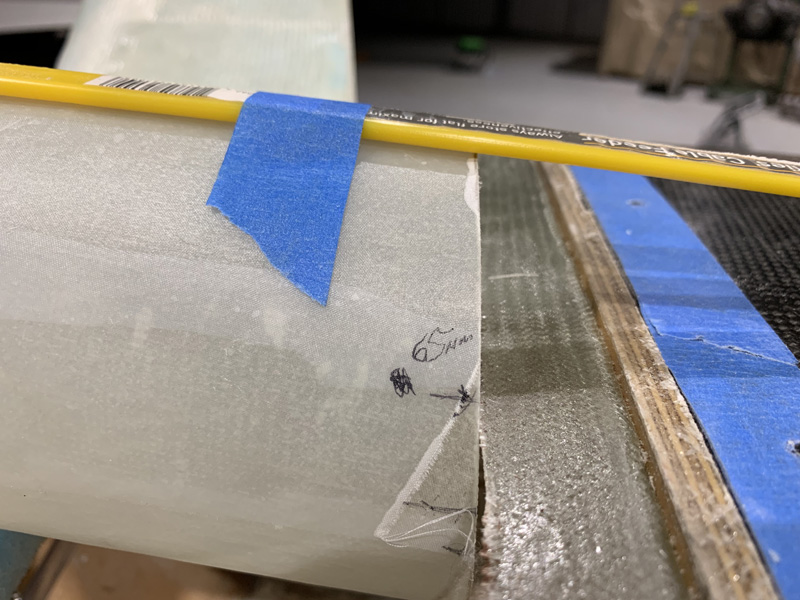

Another little job was to get the static vents placed.

Here’s one side installed. They are just press fitted for now. It will get sorted out when we plumb everything and then test fly!

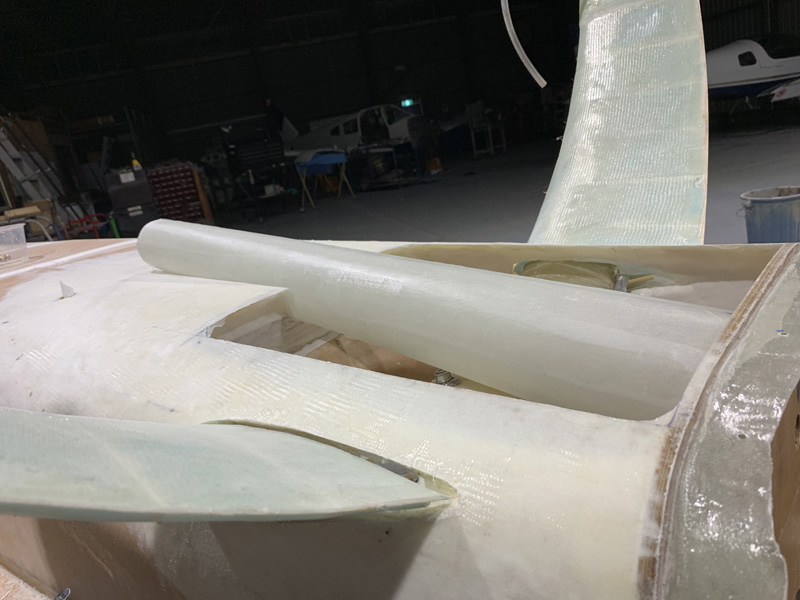

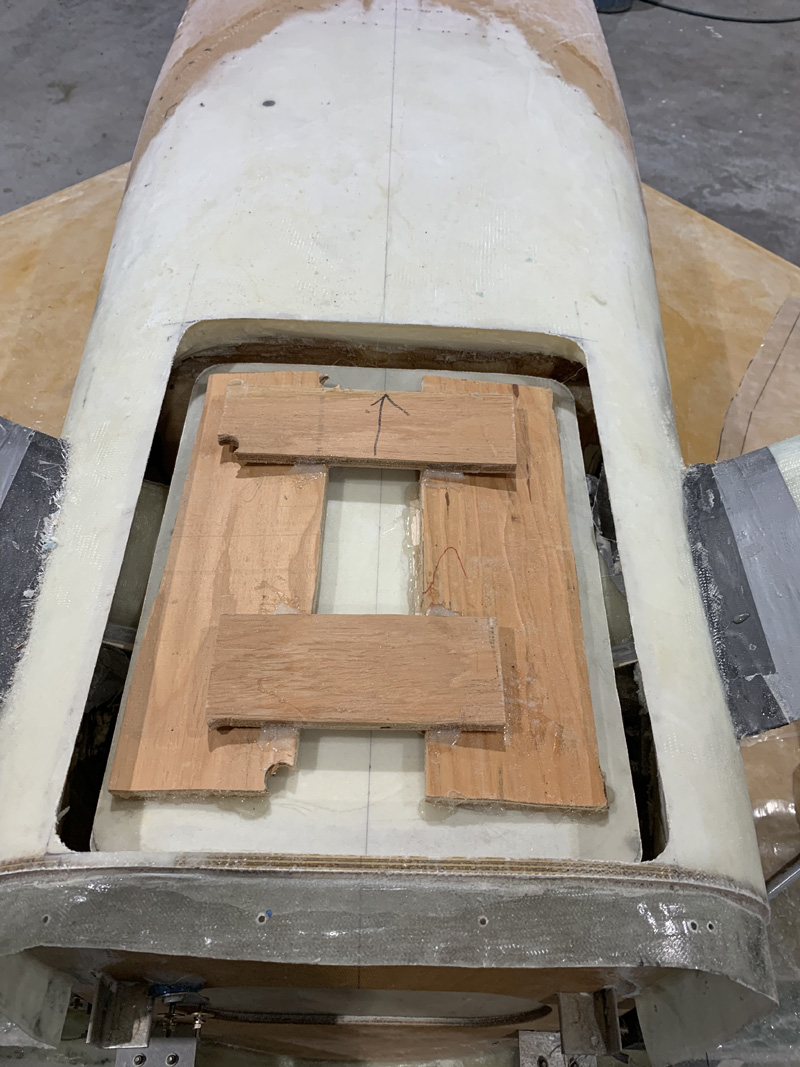

Quite some sanding and fit work was needed to get the nose gear happy to retract with its Garolite G10 nose shield, now painted, in place.

This little spring loaded cover needed a fiddle as well.

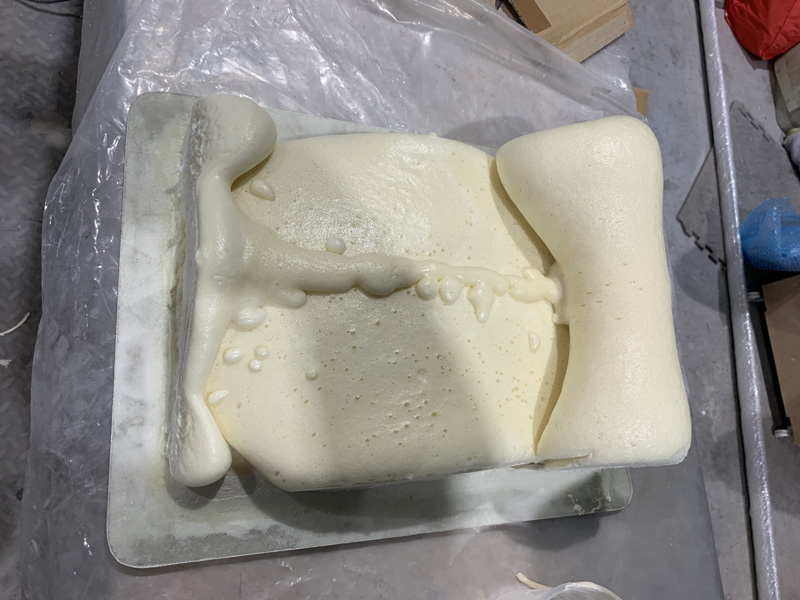

I have a nose bumper and thanks again to ‘Marco’ who made it for me. I can’t say who Marco is as he doesn’t want the world to be asking him to make them more nose bumpers. So don’t ask me OK? He does great work.

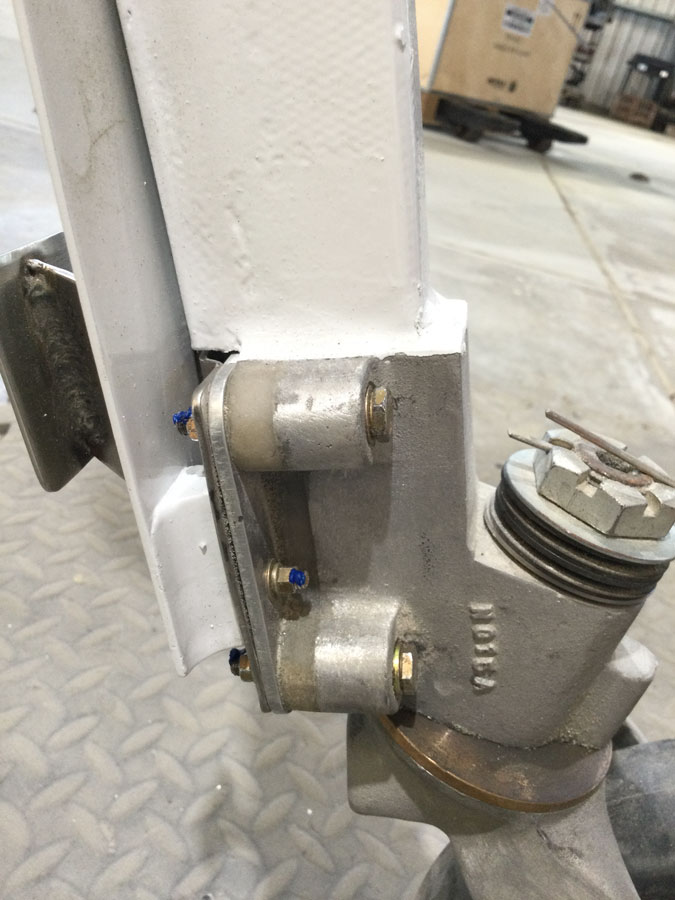

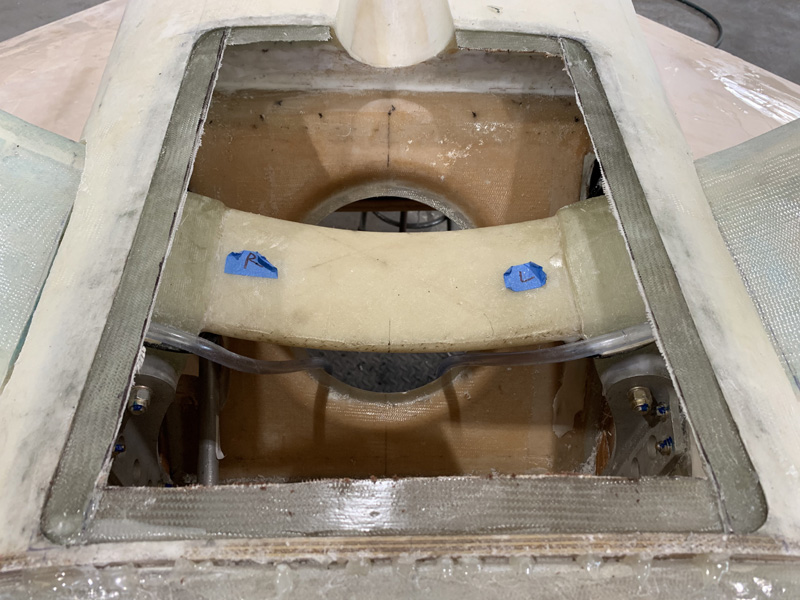

Quite a bit more work went into this nose gear. It had issues. Lateral play side to side. I had to get the AN5 bolt out holding the NG6A and it was a nightmare. I ended up making a special tool just for that and spent more than a full day trying to stay …cool.

The side to side problem was because the mushroom spacers that came with the NG6 I had purchased were a little too long. There were also a sloppy fit for the AN5 bolt. I got a precision bolt and then had new spacers machined up and those a fraction less in length. Long story short… its rock solid now.

This part seems OK and has a mod I must have documented somewhere in this blog!

The next problem was the side to side play at the wheel. WTF?? I had purchased mushroom spacers for this too that matched my wheel. NOT! These got a tickle on a serious lathe and after adding a the AN960L washer my nose wheel was also rock solid.