| Date: 03-12-2019 | |

| Number of Hours: 15 | |

| Manual Reference: no ref |

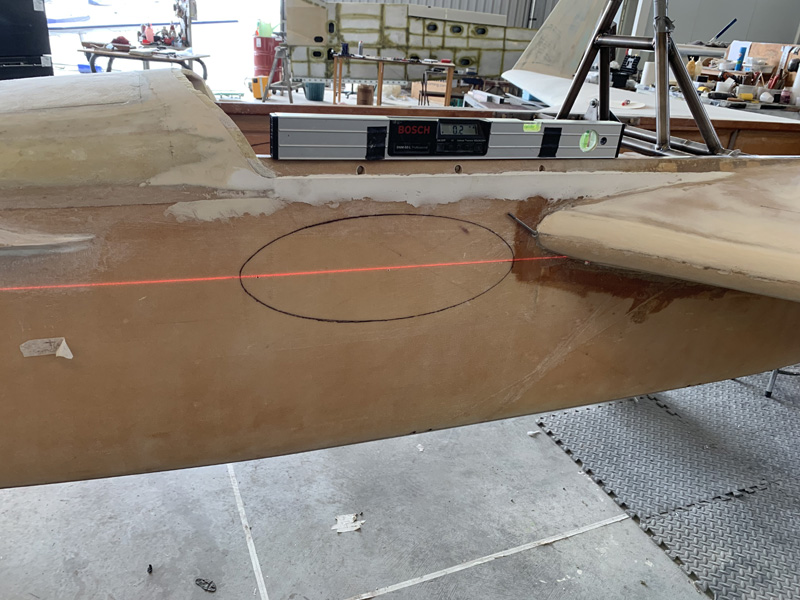

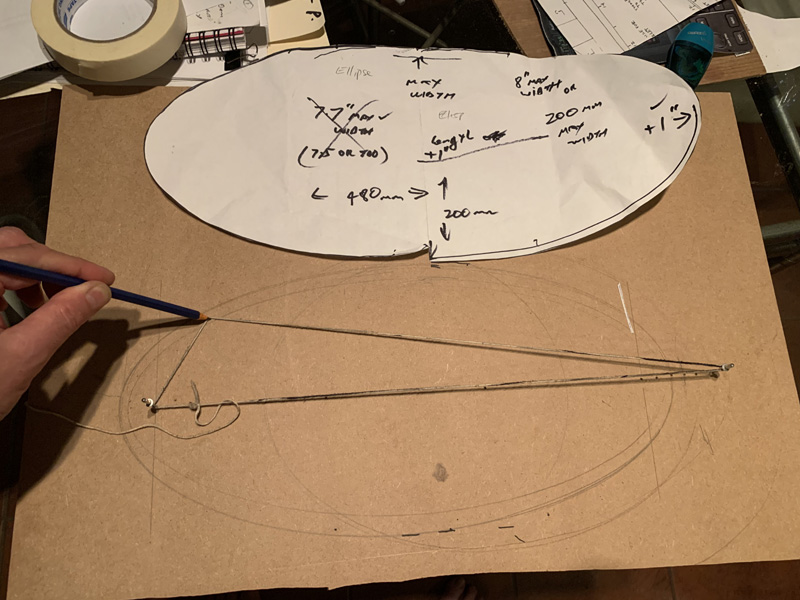

Just a word on weights. The two perspex windows together weigh 2lbs 3ozs all up. I kept the side structure ellipses that I cut out and weighed them, 12.7ozs. So thats a net gain of 1lb 6.3ozs. Lets take a bit more off for the fine cutting out and more foam removal. Then we have to add the epoxy, flox and the glass UND strips and a bit of filler. I’m going to call it a 2lb penalty overall at worst. I still consider this a great mod.

First up was cleaning all those holding sticks off as well as the hot glue on the protective window plastic. It took a while but I was very careful. The windows are almost perfectly flush with the outside skin.

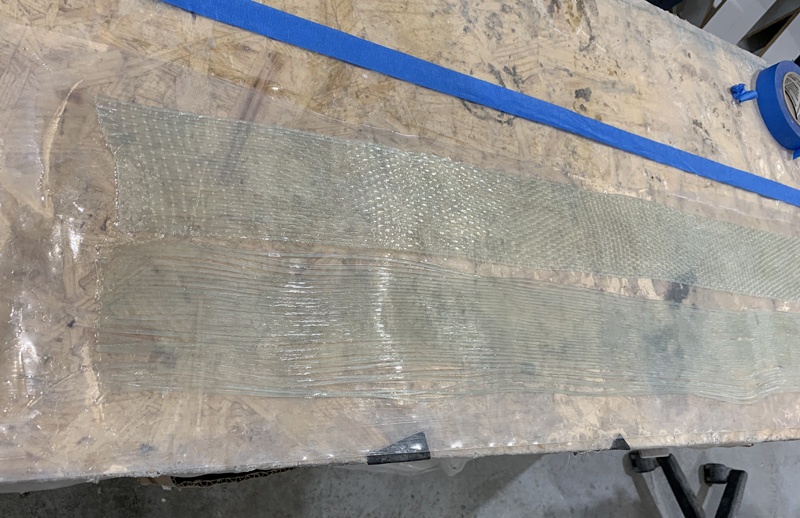

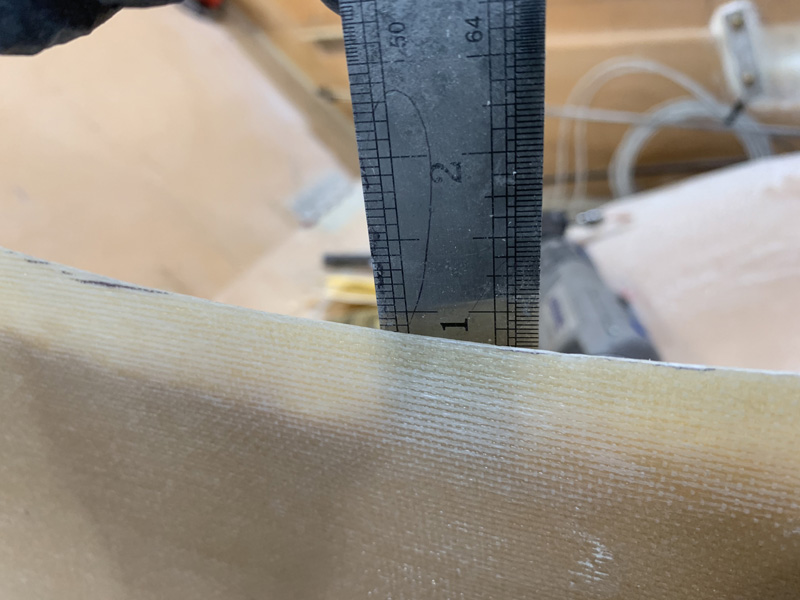

The next job was to fill that 1″ inside trough. I’ve used the same UND glass as was used on all the spar caps. You can see above the two pieces wetted out. I’ve removed the key and cross threads from the bottom one. Later the same with the top one. I used one total piece as above per side.

I grabbed 4-5 strands at a time and pushed them into the cavities with a mixing stick. Eventually the troughs were filled and then some peel ply.

After cure and a clean up the ‘ring of glass’ was not pretty but I am really confident this is very strong. Probably stronger than with no window. Certainly in compression. Maybe not in shear or twist, but still strong.

The next day, some lightweight filler.

Today I cleaned up the filler as best I could. It may need another go very close to painting the plane’s inside. At that time it may be best to remove the protective plastic and see where I am at. For now these windows are done!