| Date: 05-31-2018 | |

| Number of Hours: 8 | |

| Manual Reference: no ref |

One issue with the nose gear, particularly if you have doors, is the possibility of the wheel being cocked to one side when you retract it. If you have the manual gear you just won’t be able to get it fully retracted and will have to fly around with a bit of wheel sticking out in the airflow. No biggie. This has happened to me several times on my current Long-EZ, JZE.

IF you have electric gear with a powerful linear actuator, its a different story. If the wheel is cocked you are going to break your gear doors on one side and possibly damage the fuselage floor or even worse.

Usually if you take off smoothly the gear which has some friction on it will stay straight and all will be good. IF you hit a pot hole just as you rotate you might have a problem. If you are on a very rough strip and you bounce the gear trying to get it up early to protect the prop, well thats another possibility of a cocked wheel and serious airframe damage.

OK, it is unlikely but the penalty is high if it does happen so I wanted to make ‘provisions’.

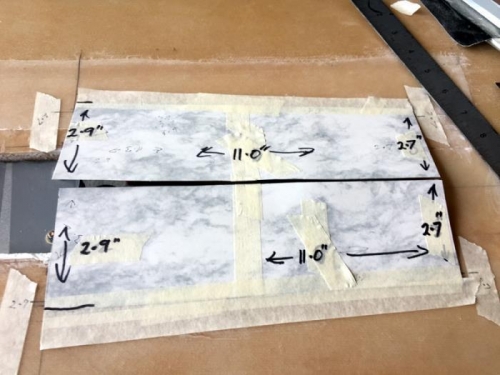

I got this design idea form ‘Waiters’ Long-EZ site. I made something similar out of cardboard and it seemed like a good place to start.

I tested it at different angles and found the optimum.

Ha! Now I spent a bit of time trying to bend that shape in metal. That’s the blob on the right of the pic. I’d call it an epic fail. Either I come up with another idea or find an RV builder to help.

My idea was to get some aluminium angle and bend it a bit more again in a vice. That’s the bottom bit in the pic. The top piece is similar angle aluminium and its looking a lot more like my cardboard model without the bad bends.

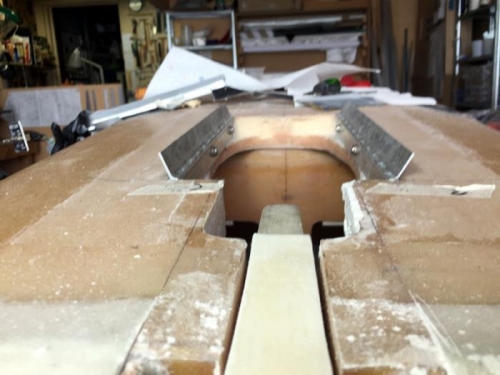

These are clearly too wide here to fit in the nose cavity but we are on our way.

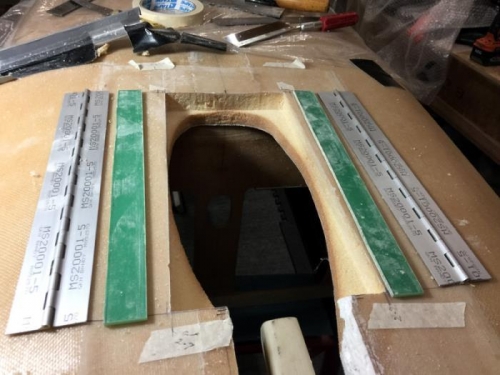

While testing the gear up and down I noticed that the wheel could get stuck on the very thin ledge that is the hinge! That was a surprise as the wheel could really get stuck here and break the doors! I was too quick, this time, to let that happen but here was another hidden issue. You can see the doors off in the pic and I then filed those edges into a nice very smooth curve which fixed the problem.

More testing, this time I hot glued some pieces together and again did the up down wheel thing. Yep it’s going well.

Confident in the design I used three cherry rivets to secure the two pieces. Then more testing to get the angles right.

When I was happy, some rounding and smoothing for my pieces.

Pretty….

It is hard to see but we are a good width now.

Can you see here that the tire is going to hit that tiny nut on the gear doors? Well another potential problem. I later moved that screw and nut 1″ rearward and filled up the old hole. Now the tire happily hits the open door, slides down that until it gets to the straightener, which then does the business of getting the wheel in the middle.

You can see here the straightener just contacting the gear door and then hinge (note the curve edge) to finally fit in the wheel well pretty close to straight. I’d call this one…. done.

Yes I will say that if the wheel is cocked beyond the edge of the doors it is going to foul up and all the work I’ve done here will not protect the doors. This is where a low value fuse comes in to at least stop the floor being damaged by the wheel. Frankly if the wheel is cocked this far to the side some other bad things have already happened. This little mod above mitigates most reasonable situations that could be found in normal ops.