| Date: 05-11-2019 | |

| Number of Hours: 6 | |

| Manual Reference: |

Time for the ‘other side’ reinforcement plate.

What is the ‘cost’ of this upgrade? The benefits are less likely main gear failure, particularly at higher MAUW. It is more weight at the rear end too, exactly what we don’t want. 1lb 9.6ozs is the estimated all up weight penalty.

This is significant. I am doing this because I will be a heavy Long-EZ with full fuel, if I have to land back with 550 liters on board, thats 396kg or 871lbs. I could be in the 2000lb range all up. That would be exception circumstances, after a long flight of course fuel is burnt off. Then there is the unexpected pothole consideration too. I have set the MAUW of the plane at 995kg or 2180lbs in the paperwork which I can as the manufacturer.

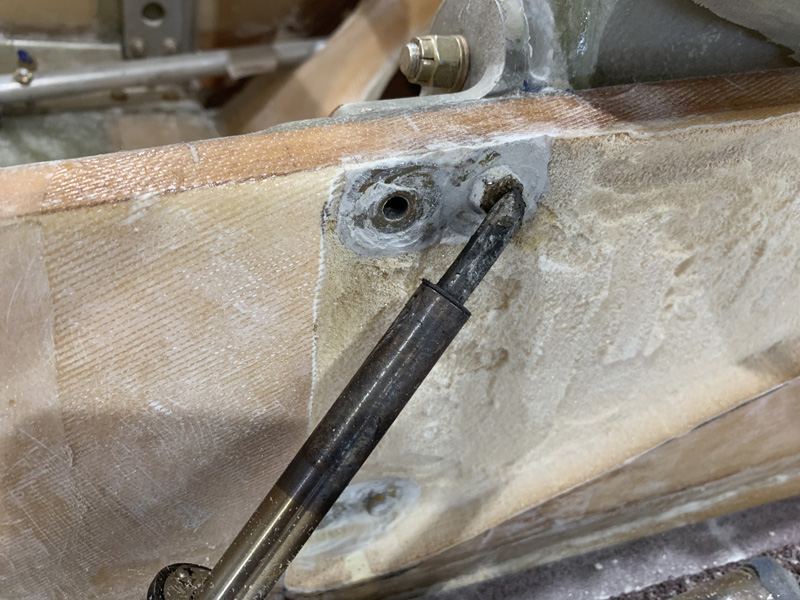

The side had some challenging bolts to get out. The one above took 2 hours to remove.

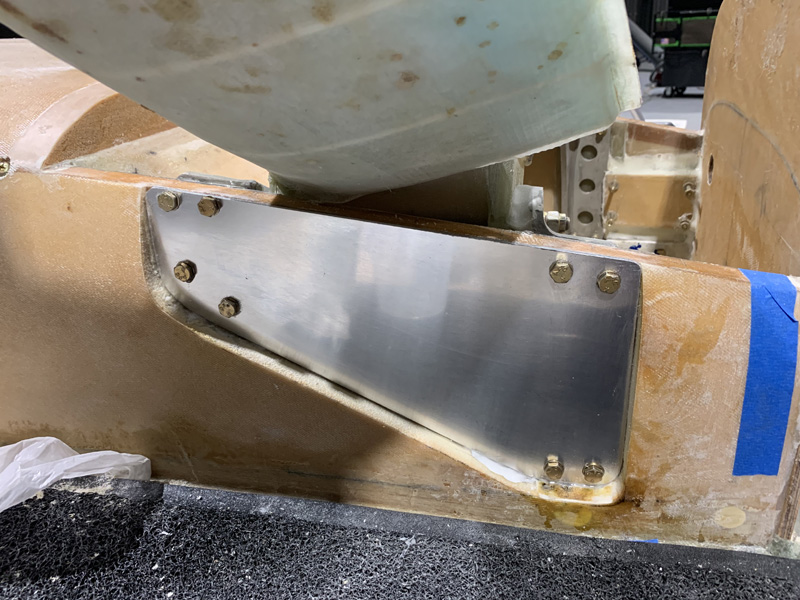

Finally I got the plate blank fitted.

Again the blind hole matching trick worked very well.

After a lot of clean up and plenty of flox in the bolt holes I completed the second plate after three long days. All that remains is a final torque of the bolts after the epoxy cures. The plates still need to be covered in foam and then a structural repair to the outside of the fuselage.