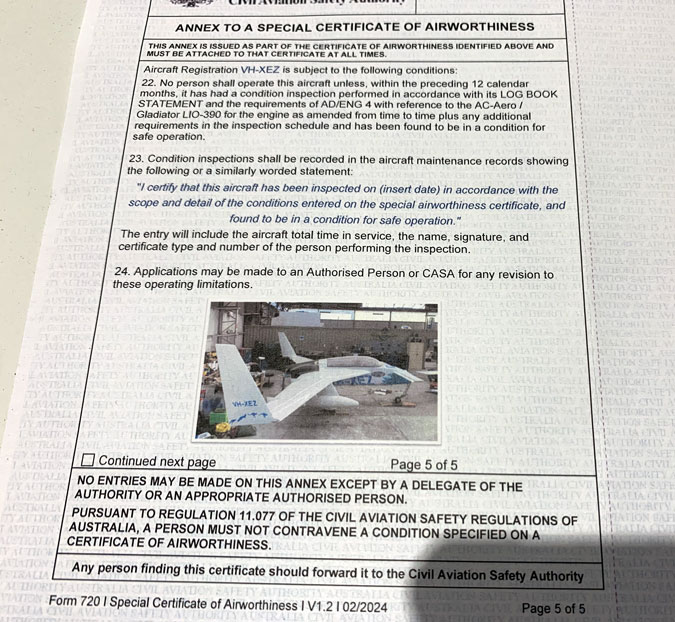

| Date: 12-17-2024 | |

| Number of Hours: 9 | |

| Manual Reference: no ref |

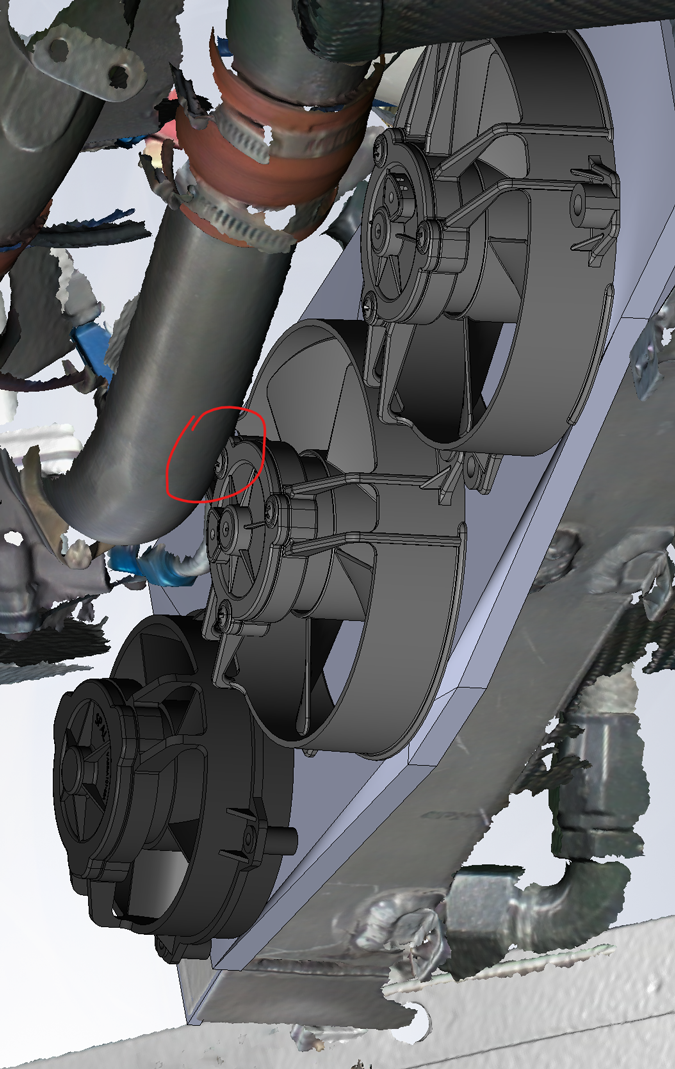

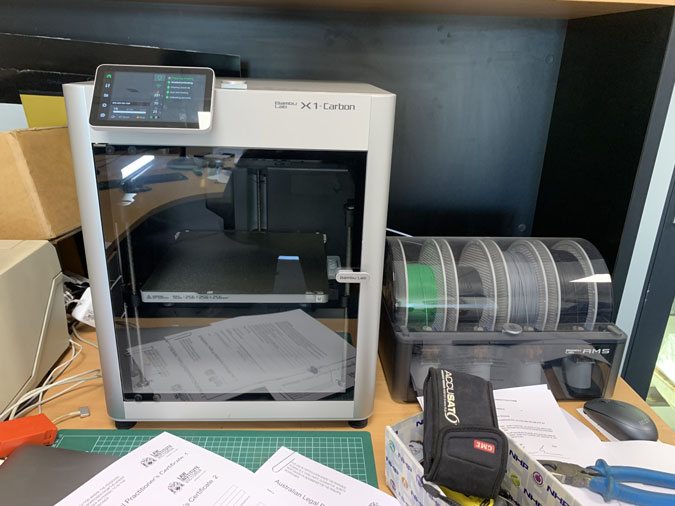

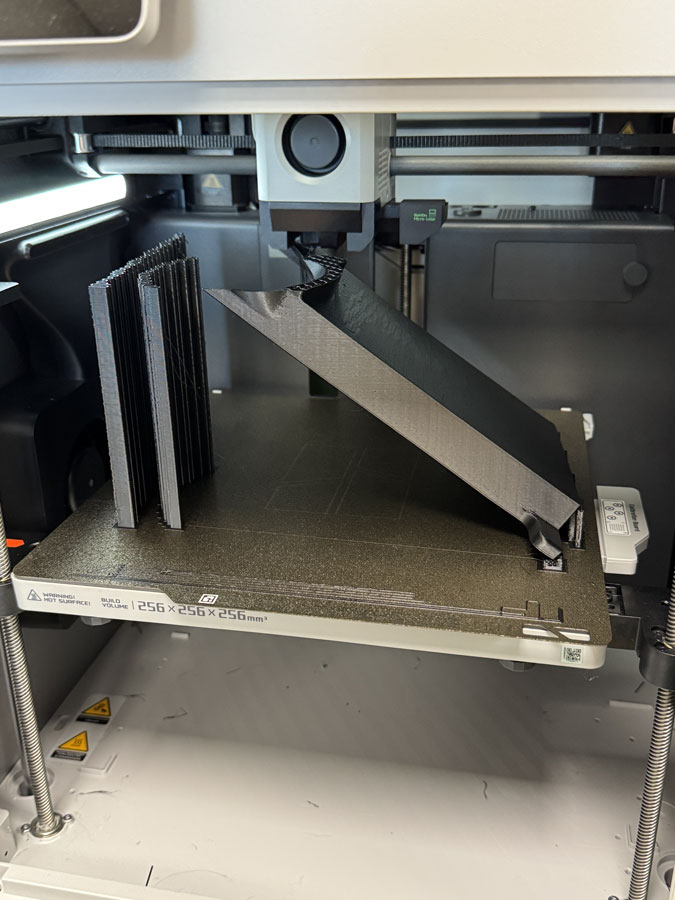

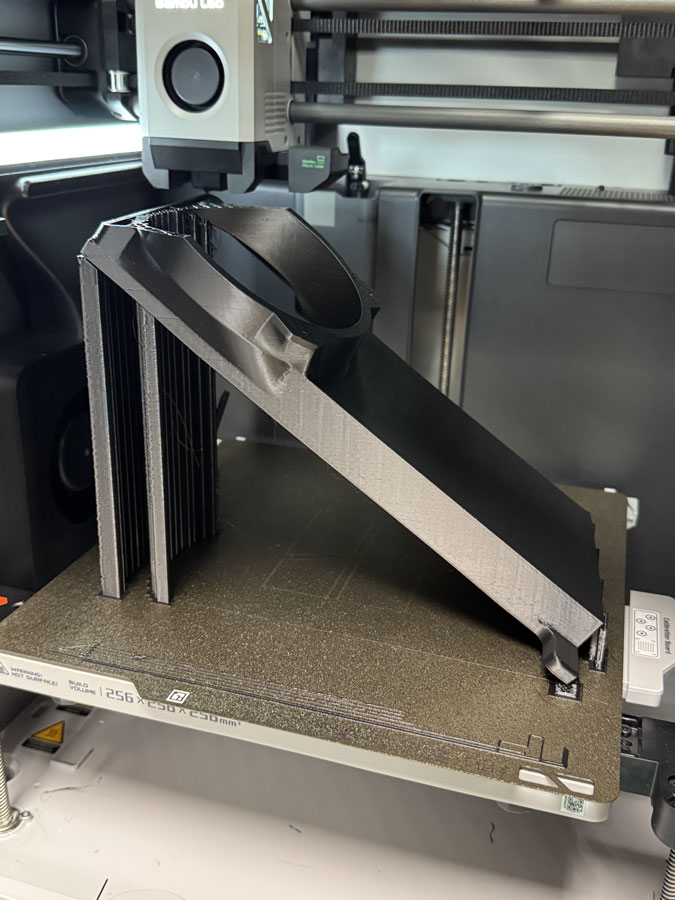

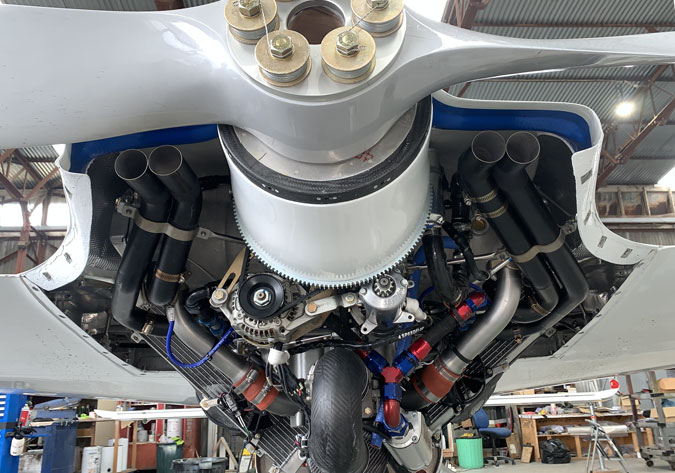

While working towards the next ground cooling test in the runup bay I began a side project. If this fan and shroud thing doesn’t work then I’d better have a Plan B. That would be openings in the cowls leading to cowl flaps. My testing said bottom cowl off, top on was pretty good for cooling. So I need to try openings in the bottom cowl right?

I don’t want to cut up my good cowl just yet so I need a dummy to work on that I can throw away later. A test piece.

Those two bits of carbon were around $200 and then I need a lot of epoxy. It was a meter of cloth per layer and that was barely enough. I think three ply would have been better but this is going to just be for testing and only needs to hold up to taxi out to the runup bay and back.

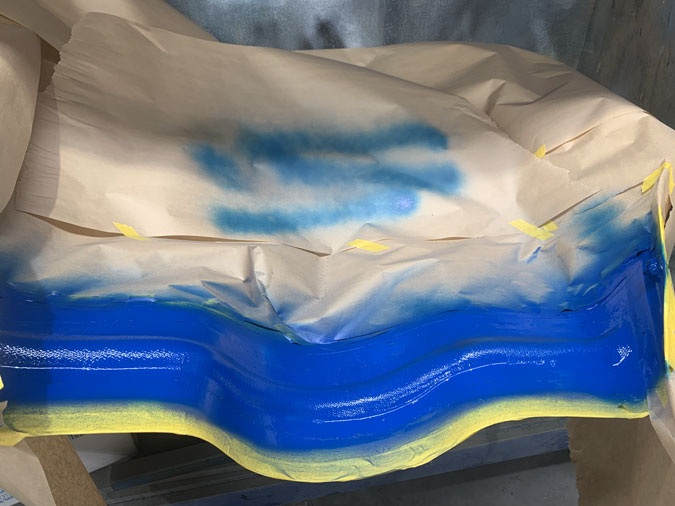

Of course my ‘mold’ or plug was already made. I just covered the original lower cowl in duct tape. I did use some wax on top as well. I will use a lot more next time or hair spay or even proper mold release.

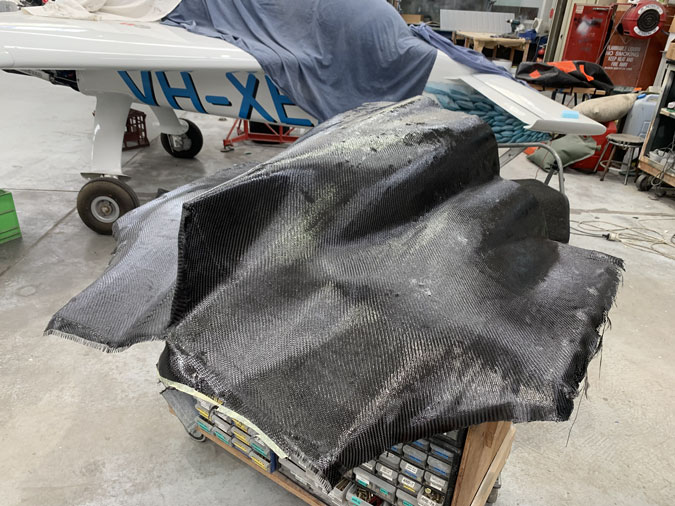

Yes not pretty. The carbon was a little wetter than usual. Remember its a throwaway.

I managed to cover the whole cowl and gave it a day to cure..

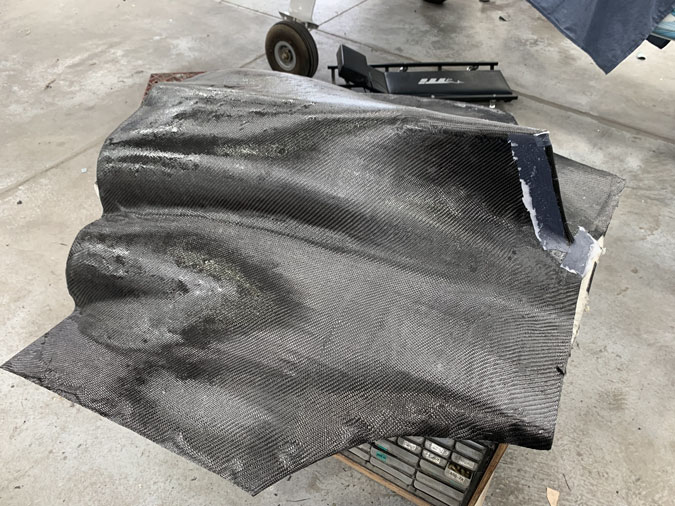

It was VERY hard to get this dummy off the mold, probably because of the compound shape. It looks a bit better on this side.

Here we are off the mold. I did a bit of pour foam on the boat tail later to stiffen it up. Overall I have what I wanted.

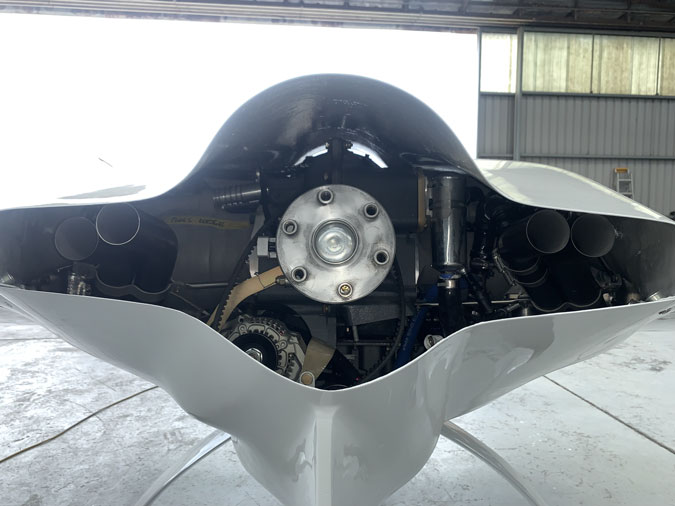

The ‘dummy’ lower cowl does fit well enough.

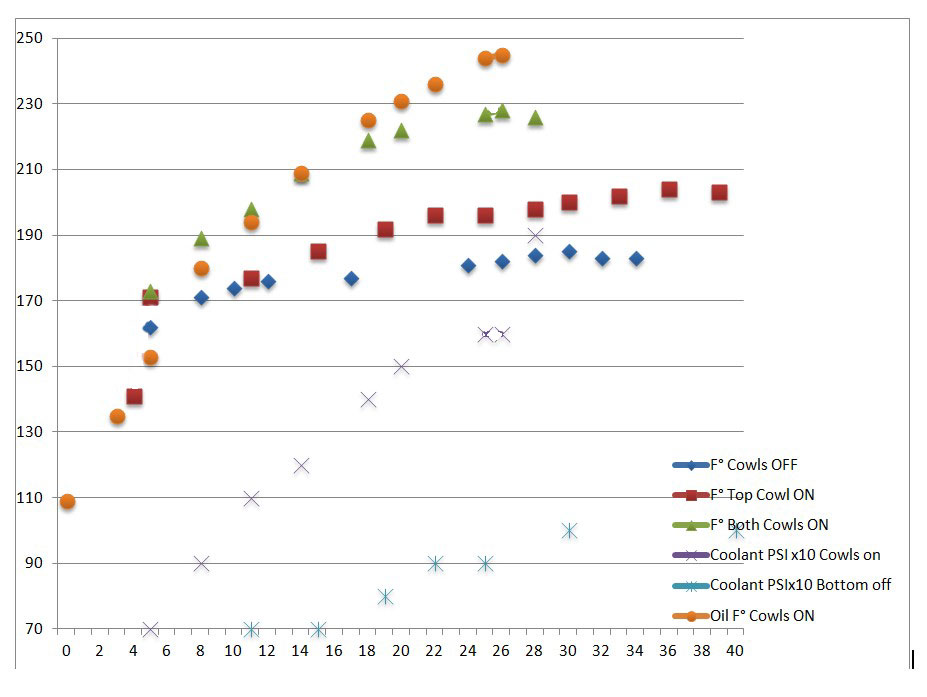

Here we are a couple of weeks later. I’ve done several taxi test runs keeping good temperature data. I am going to need cowl flaps, no question. I have cut out my ‘flaps’ and I will report on the success or otherwise in terms of cooling. If it goes well, then making flaps that open and close will be quite a challenge. Its a good thing I have this mock up to try stuff out with.

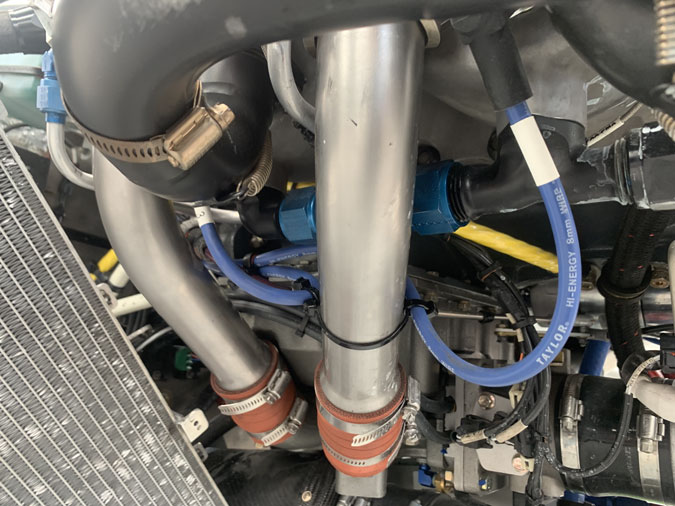

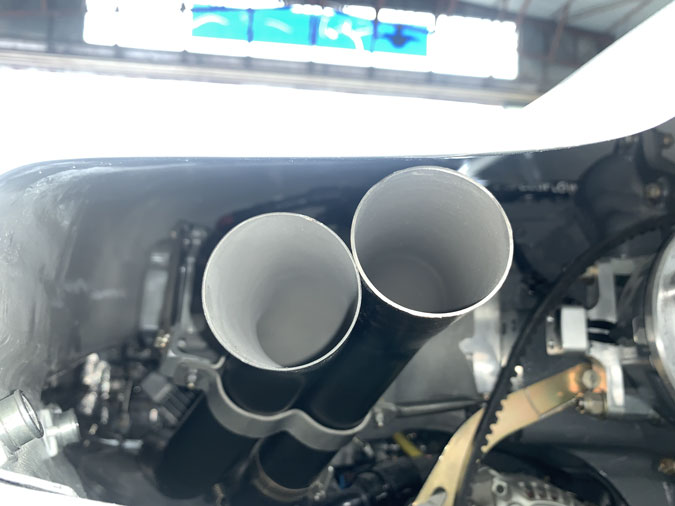

Left side, note how I’ve gone right where those hot exhaust pipes are.

Right side, the same size cut out. Even with the pipes being in different places with the cylinder offsets I wanted them the same size and place. If I need them in flight I want the drag from the doors to be equal both sides.

It doesn’t look too bad, of course I am going to have to have them close in flight. This opening only setup is firstly to test the concept. I did do a test run Dec 31, 2024 but a LOT of things have gone on that I need to tell you about first.