| Date: 03-05-2018 | |

| Number of Hours: 8 | |

| Manual Reference: 18-8 |

This all took several days to get sorted out.

The canopy stay on the pre welded upper section on the rollover was simply a fail. I might use it as a camera mount instead. Other people have got this working, it is not for me. I see too much twisting moment on the gas strut and I think it would always be on the verge of twisting out completely.

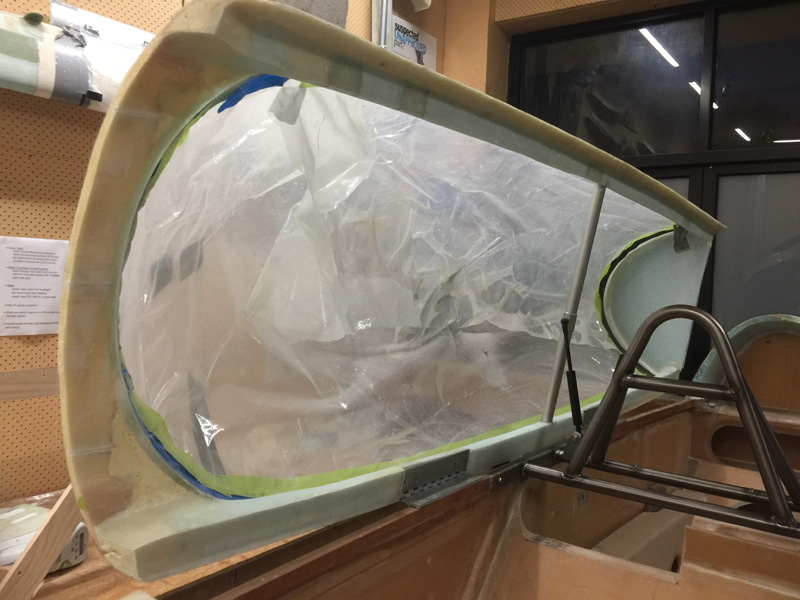

A better position is in the above picture. This keeps the strut in the same plane as it moves.

I worked out that 2″ above the middle of the rollover tube was going to allow the strut to clear in all positions. You can see I had a few goes with my test piece.

Once I had this decided I made up a drawing and arranged for a piece of Titanium to be welded on.

Here we are all done. I spent a full day with 7 hours in the car driving and 90 minutes of waiting time in between. It was not pleasant on many levels. All I care about is the fact that my piece is welded on securely now. The disagreements and difficulties getting this plate done correctly, like much of the build, is already in the past. The few lessons learned in the process will, of course, stay forever.

Another day of running around. I went to the site of the gas strut manufacturer to get a longer end piece. After quite some searching the kind people told me the part I wanted was out of stock but they gave me the black piece above. Once home I got to it with a grinder and released the ball!

Another task was to pick up some 1-1/8″ OD tube from fellow builder. Darren. Thanks! The idea here is with my now longer bolt I could reinforce the hole in the tube with a large surround washer that is really just another bit of tubing of slightly larger OD.

Here both halves of the support tube are in place. I am very confident I have the strength I need now on the strut. Yes no washers, I know. I wanted that lock nut to engage fully. I may find one with a lower profile and bring back the washers. Tell me if you care.

This is bolted in position. You might see or guess that when the canopy comes down there is no twisting with this geometry and everything is in line.

The canopy strut works! I also removed all the supports around the canopy. It is on and working. I’ll just continue with the latches. We can call the canopy strut – done!