| Date: 03-01-2018 | |

| Number of Hours: 6 | |

| Manual Reference: 18-8 |

This canopy stay is another one of those items that gets a huge amount of thought. I quite like the one I have in my flying plane, JZE. The design is from CP30 page 8. It pivots from the center of the plans rollover for its geometry. As I have a non plans rollover I didn’t know if it would work.

So I made the CP version and tried it out just by holding it in position to see where it would actuate. To get the full benefits of the over center effect it needed to be where I couldn’t put it. Then the mechanism’s travel would hit the back of the rollover supports anyway. I really wanted to do this ‘stay’ as I could then have used a composite lightweight canopy spreader which would expand and contract with the canopy, in theory.. Its a NO GO, so on to plan B.

A lot of guys are successfully using a small gas strut from Aircraft Spruce #05-01177 which I’d already bought as a backup. They are pretty cheap. They do require a LOT of force to close and that meant the end of my lightweight spreader. I needed aluminium ‘side forces’ strength and sourced some 1″ tube. This matches the rollover tube and as the ferry tank might push against it, round is the right shape.

The two pics above show how I figured out where to place the tube. Its hard to see through the canopy so I just added some spacers to ensure it would close and be equidistant from the rollover.

Next up I used some filler bog to hold the bar and test if the strut was going to work. It does need a lot of force but the weight of the canopy makes it no problem. I still have the issue of getting it in the right place and then securing it to the tube. Yes it will work. Some more testing is needed for the exact placement. This meant I’m good to go ahead and put the brace in for real.

I just made a couple of holes in my chosen spot and floxed the bar in. I was amazed that the ‘bog’ was strong enough to hold it so a little flox is certainly going to be sufficient.

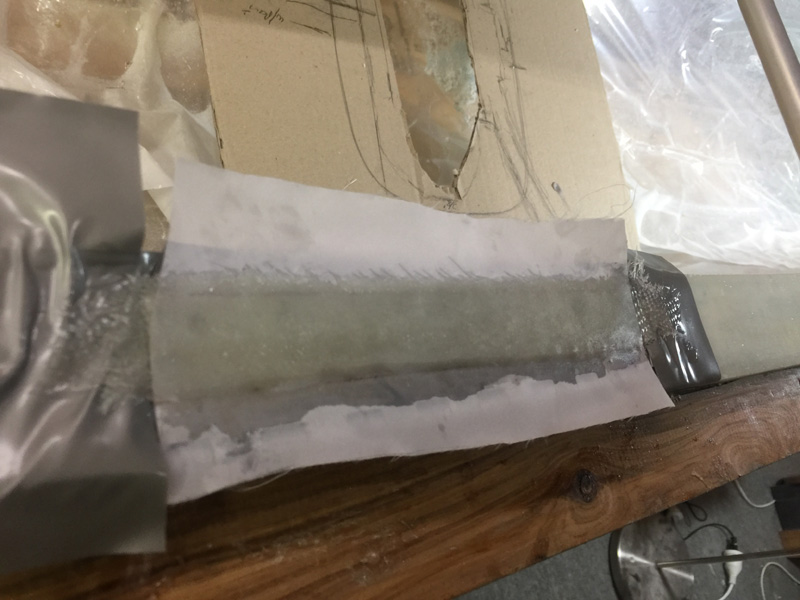

While I had some epoxy mixed I did a six ply layup on the hinges to pad them out a little given I made the cutaway for them deeper than required. I want the canopy position set before doing the latch hardware so its worthwhile to get this done now while I have the thing off the plane.

The ‘pole’ is in place and once cured I can work on the latches and the canopy stay.