| Date: 12-18-2017 | |

| Number of Hours: 10 | |

| Manual Reference: 18-2 |

Yes second fitting. It is a very tedious process.

I started out after a lot of measuring with my old dremel that I’ve had for about 20 years. It still works well as a routing tool.

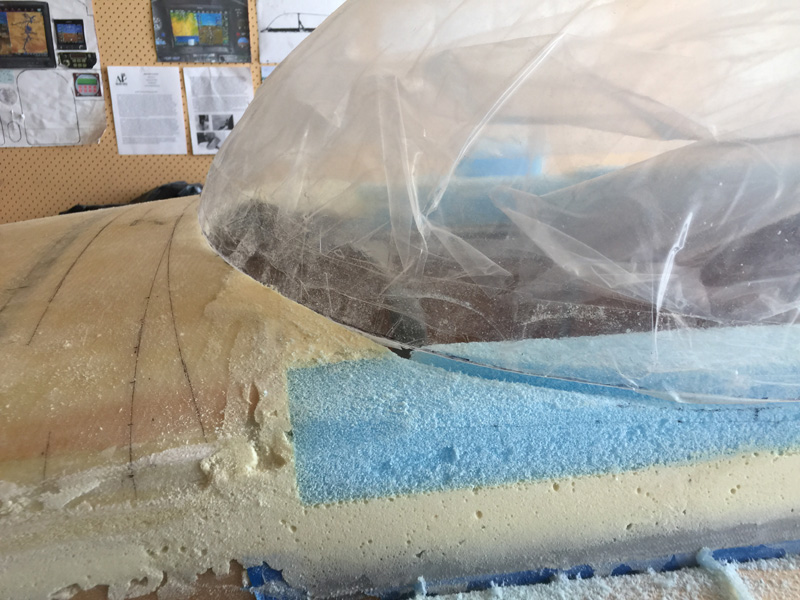

I made a ledge in both sides and also made room at the front for the canopy edge to fit past.

Over a couple of days I have cajoled the canopy to sit on the canopy rail. It has taken dozens of trial fittings and working slowly with my permatgrit files to get the canopy sitting correctly on the ledge. I had to add a half inch of foam at the back and accept about 3/8″ off center for the canopy itself. Again while I have all my centerlines it just wants to sit slightly to one side and who am I to argue?

I got a pretty good result on the right side and the left has a bit of a bulge that I can’t do anything about. Its just a fault in the way the canopy was blown. All this work has compensated for an odd shaped canopy that I received, particularly in being far too wide. I am close to a fit I can live with despite the disappointment. Its just not worth another 3 or more thousand dollars to get it perfect. You see, after all this time I’m not the perfectionist your thought I was. HA!

Below you can see my low tech method of shaping the rear turtleback. Its a Japanese pull saw and perfect for shaping and cutting foam blocks.

Here you can see I’m a bit closer to the turtleback shape. Tomorrow its a steel ruler for a straight edges and a 12″ sanding block to slowly get this right.