| Date: 12-06-2017 | |

| Number of Hours: 6 | |

| Manual Reference: 18-1 |

I’m not to sure where to put the work of preparing the nose section for the canopy. It is very much canopy related so thats as good a place as any. I am getting close to making the canopy rail. First up I need to prepare the nose section and get a final height for where the canopy sits. I may have to trim it a little more.

I have the canard cover sitting nicely at the rear edge but exactly where the nose cover and hatch goes was determined today. I’m raising that canopy cover at the front and also raising the hatch piece forward of the canopy lip. This all relates to the side angle aesthetically and how high my instrument panel will be. It was sitting at 8.8″ above the cutouts, plans is 9.2″ but now with modification I can get it up to 10″ in the middle. Wohoo! The extra space will solve some other problems of fitting the avionics.

This does mean I’ll have some gaps to fill in over the canopy sides as you can see below.

I’ll also have some serious gaps at the sides. This is how I’m getting a bigger instrument panel. To confirm this would not effect my forward or side vision I was forced to do some hangar flying. I really like sitting in this plane. I also noted the extra 2 inches of headroom I’m getting from my non standard canopy is really going to help vision. I’ve put a block of timber in place now and hot glued the canard cover in position so now I need to ‘make good that area.

It was also time today to decide where I want the canard cover to be cut out from. Time to draw a line in the sand on canopy position.

Where that curve is will be my cut out line for the canopy. I decided on a bit of structure here and a little bit of IP security too by going rearward. You can also see I’m using a ‘spline’ to make a curve to draw my lines in.

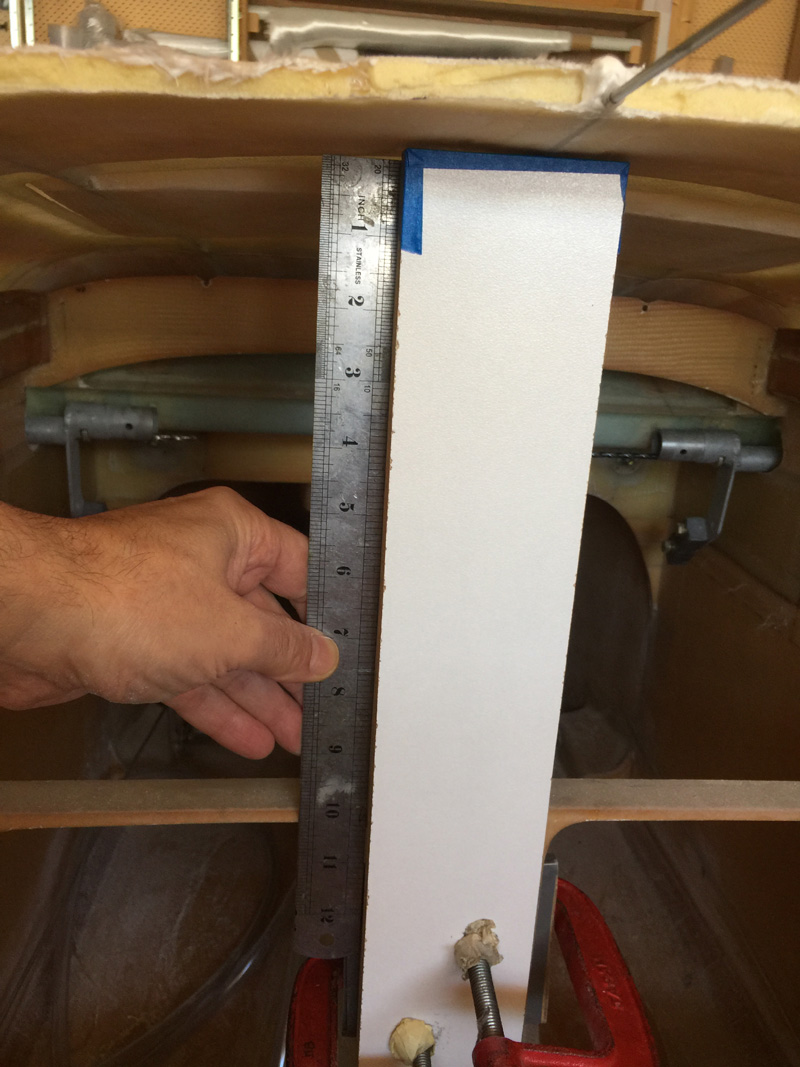

The next thing I realised was that there is now a big gap above F28. I made a filler piece of the same foam density, R250, and glue it in place with 5mt and flox and then glass it with 2 plys of BID. This is all about getting that area structurally strong. I will seal it with tapes later.

I’ve sort of gone backwards as I thought I could start adding foam to the longerons today but I now see this is a necessary step while I still have easy access.

Glassed and peel plied. Lots of little decisions were made today. It seems like only that filler was added but I really have a better idea of how I’m going to set the top piece up now. I needed a very small gap there too as the top piece has a fitting tab which goes in the gap. That will get glassed in place.

I’ll add foam to the longerons but leave the outside as a part of the canopy frame outside lay up. Meanwhile I’ll need to do internal tapes to get things strong forward of the canopy and I.P. It is slowly coming together.