| Date: 03-07-2018 | |

| Number of Hours: 10 | |

| Manual Reference: 18-10 |

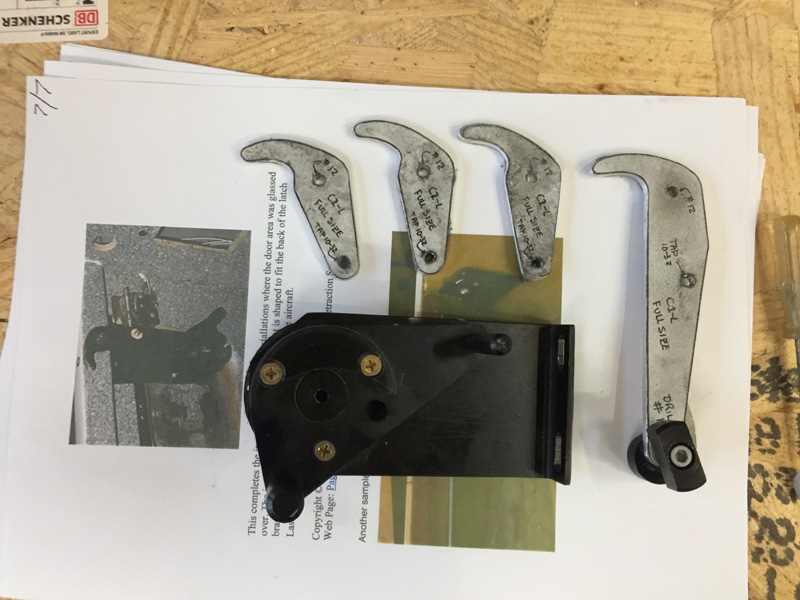

I found I was short a canopy latch and fortunately these are pretty easy to make.

I will be cutting the top off the longer latch. More on that later.

I tapped the holes out to take machine screws

Yes I spend maybe a full day finding the correct positions for the latches. As usual its not ‘per plans’. Drilling out of few holes was a full day’s work in the end. …and the holes are not quite exactly where I wanted them after all. Close enough to fix with new latches <sigh>.

I can say the holes are all parallel and straight – so thats a plus.

I’ve set up the latches with some temporary tubes. I really want to get this right as my actual tube stock is rather limited to one try only at getting it spot on.

I had to make some ‘alterations’ yet again in the rollover to fit the latches. This particular latch will end up bolted to the rollover rather than through then longerons so it will need special ‘not in the plans’ treatment. The round hole is where my hot air outlet goes. I’m going to have to move that about half an inch.

Here’s the temporary setup. The Wilhelmson rotary latch will be where the long handle is. This works out for where the strakes will be, where the windows will be, where the sight gauge will be and most importantly where my elbow will be.

This shows the end block. There are two of these and two other fittings that were made up for me in a ‘machine shop’. I think you need proper metal working tools to get these nice.