| Date: 11-07-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 10-8 |

Ok after some days and a bit of lost sleep. The plans say to do 1″ of peel ply on the bottom layup. This is to ensure a glass to glass bond at the top TE later. Those words came from the GU canard days which I can see in original plans is a little different.

After asking smart people, being told about a CP with closeouts listed…I finally looked in the right place in the Roncz plans on my table where it is clearly marked .5″ glass to glass at the trailing edge. Doh!!

Now I had a full 1″ of peel ply buried under the foam and it all had to come out. So in the process of removing the fish tail I also had to remove a lot more foam than I wanted to. The choice was then to just smooth it out and do a LOT of micro later… or add a bit of foam and smooth it out until I had a nice clean edge of .5″ So thats what I did over a couple more days. Fast set epoxy would be good at times like this. I don’t have any.

It look ages anyway to get the foam clean despite the peel ply. I would have saved a lot of time if I’d just left it out and ground off the epoxy and foam residue. Oh well. Done now.

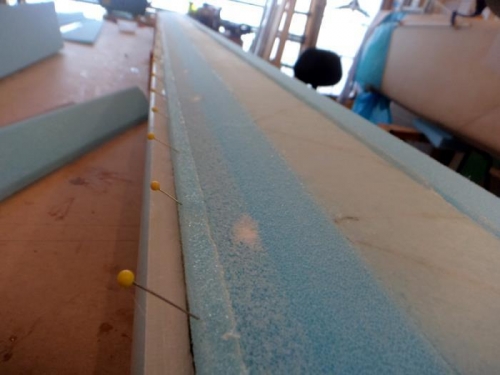

As you can see I pinned a sliver of foam into place and in pic 3 its all smoothed and ready for the next step. That line of white in the pic is the micro join so you can see after the runaround thats the only bit of extra weight and its very little indeed. All good. Move on.

Cut back to remove peel ply

Add a fillet

All good again