| Date: 01-03-2015 | |

| Number of Hours: 5 | |

| Manual Reference: Roncz C sheet |

This is a simple little layup. Of course I spent ages carefully trimming the tip to ensure elevator clearances would be OK. Its one thing to have a really small gap. I’m thinking I don’t want it to jam in flight.

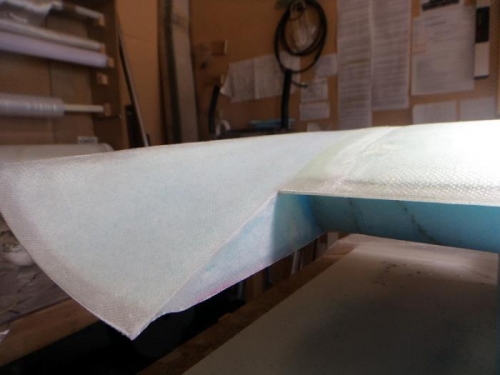

Once the gap was correct, time for a good clean out for the flox corner as in pic one. I filled the hinge pin hole with really stiff micro, did the usual slurry on the blue foam, pure epoxy on the glass bits and I made a template and cut out the one ply of BID with a 45 degree bias on foil. All the necessary steps despite such a small layup.

It all went well and I cleaned up the edges the following day as you see in pic 3.

Flox corner trough

One ply BID

Cleaned up