| Date: 02-17-2015 | |

| Number of Hours: 10 | |

| Manual Reference: 25-1 |

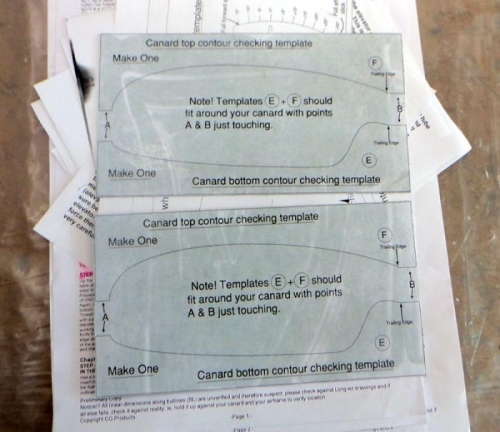

Seems a little early for finishing yet I have an idea that I’ll get a more acurate canard and correct incidence if its contour is correct. The open EZ project has templates and on it is a ruler so you can check that the copies from the pdf are the right size. I had one printed a while ago and these matched pretty closely to the Eureka CNC templates. However the Eureka ones are not 100% and I’m calling the Roncz plans good… which also match the open EZ plans. My next copies however were 0.1″ out which is a lot and that took a couple of days and many hours at a print shop to get sorted.

I bought some 1mm or about 0.040″ sheet aluminium, 5mt the paper templates to the metal and cut them pretty close to the line on my band saw. Oh, and the switch broke on that so it was a few more hours getting a new switch. I then spent a couple more afternoons cutting these two sets of templates with the fine work to the line on an upside down dremel sanding drum and a lot of patience. Then a bit of hand sanding and I had two templates made separately but very very close to each other.

Why two sets ?…back to the TE of the canard needing a tweak with the heat gun due to the counterweight straps causing a loss of range. This means that the last 3/8″ or so of the TE in places is out of profile and goes up… so I needed a template with a notch in it as well as a perfect one. You can see the second one at the front in pic three has the slight cutout.

The pics also show that I have a nice radiused spar cap as planned and I think I won’t need too much filler. I’ll be using 410 BTW and an ‘interesting’ profile method that I will detail. Oh yeah and I’ve been lightly sanding and using scotch brite to get the shine off the glass. Bit more to do yet.

Templates on metal ready for trimming

Trial fit

More trial checking