| Date: 05-02-2016 | |

| Number of Hours: 15 | |

| Manual Reference: 25-4 |

was doing this in March 2015. Time to get it right. I have set the canard on the fuselage exactly as it was when the wings were lined up using markings I had saved. I’ve moved to using West Systems 105 resin, 205 fast hardener and West 410 filler. While not structural this is proven for faring work and sands really well.

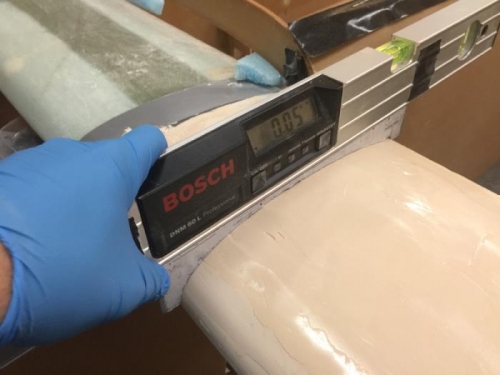

I’ve made another profile template from the plans but this time in aluminium which leaves marks on the filler giving a sanding guide. The profile has a little ledge too which fits the digital level nicely. Previously I tried to use the minimum filler and kept going down to the glass before I got the profile right. All that work is gone with more filler on top now.

I need to not only have a perfect profile but I will get to 0.1 of a degree or better which is a kind of creative thing even though its precision work. There are many hours to go yet but I can see a result possible.

Then of course I have to turn the canard over and do the underside! Ahhh there are a couple of weeks left of on this job for sure. There isn’t a lot to put in the log. I seem to get close and then find I need more filler which means almost starting again. I need to get the canard straight horizontally too of course as I sand. Finally NO waviness over the profile will make a big positive difference to flying qualities. Wish me luck!

Back on the fuselage

Getting closer

More fill and sand