| Date: 06-04-2016 | |

| Number of Hours: 10 | |

| Manual Reference: Roncz B or C |

Opps. When I went to cut out the fuselage sides for the elevator tubes I eventually noticed that the rotation part of the tubes was in the wrong place. I had moved the plans position for these Cozy fittings thinking that this way I could hide the bolts where the tube is connected to the elevators.

Wow I got that wrong!! …and it took 4 days full time to fix. I’ve done this in two log entries and under stated the hours at 5 per day HA!

The inboard elevator hangars had to be removed, the elevator tubes shortened and the hangars re installed. Pic 1 shows that I’ve clamped a heavy duty soldering iron to a hangar and once it was pretty hot, I dug out some flox around it and after a while got the hangar out without damaging anything.

Pic two shows I’ve filled up the old slots with micro. The new hard points are microed in per plans. Oh and I alodined the hangars to reduce corrosion and increase adhesion to the flox.

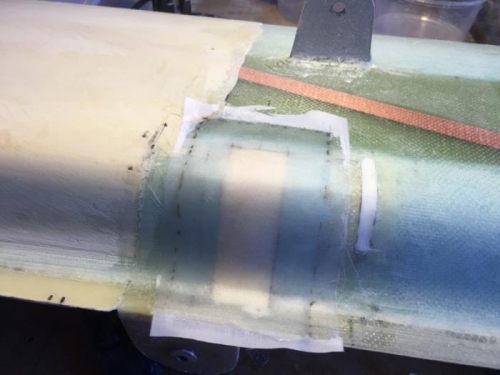

Pic 3 has a couple of plies of BID over the top as this step is usually done before skinning the bottom of the canard.

Removed a hangar

New hard points

Cleaned up and BID covering