| Date: 08-26-2018 | |

| Number of Hours: 12 | |

| Manual Reference: no ref |

This is all about sealing the canard at the fuselage so I don’t get nasty cold air into the cockpit when I don’t want it. If I want air, I will use the air vents. Leaks are not allowed.

The first step was to install the elevators and assess what needs to be done.

Elevators need elevator pins installed. I have been dreading this as it was really tough to get them out last time. What was I worried about? It only took FIVE hours to get the first pin in, …and there are two pins, one per elevator. Secrets are that I sanded down, or smoothed the pins first with 800 grit wet and dry paper. Then I covered it in Vaseline and packed the hinges with the same. This helped. I also drilled a wider access area in the Cozy Girls offsets just where the pin aligns. That helped too. I used vice-grips as above with a lot of tape wrapped around the pin AND all that green rag. This helped. I got it done.

I made problems for myself with a cascading series of issues created by one small modification. Why do I keep doing this? I went from the plans upper pin locators to AN bolts instead. Then I realised I needed to access the bolt head at the canard because of future avionics being in the way. So I had to re-locate the nut plates for the bolts from the front to the rear. This now meant that my canard cover had to be removable. This also meant that I have a LOT of air gaps that need sorting out. As a final insult to self… I raised the nose angle to allow a higher instrument panel. This caused great gaps in the canard cover that previously was a perfect fit.

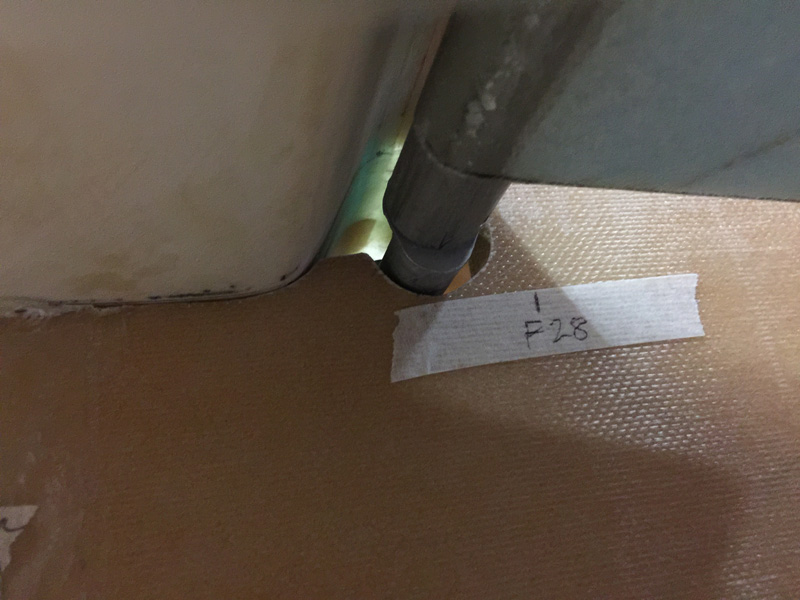

A fresh issue is the gap at the fuselage for the offset torque tube. It rotates in a circle unlike the plans elliptical motion that I cut the fuselage for some years ago. Now I just have a round area to plug.

There are giant gaps at the back and the front of the canard relative to the fuselage that also need addressing.

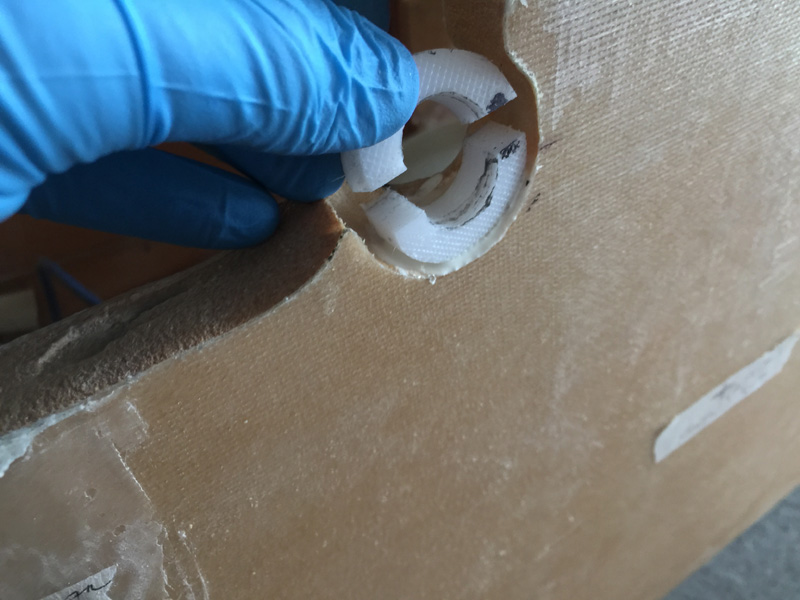

Here’s my torque tube solution. I went to the supermarket and bought a cutting board which is made of phenolic, just like in the plans for aileron wing fitting! I also bought a 3/4″ hole saw. The same OD as our torque tube. I drilled out a hole and then very carefully cut it in half with a very thin bladed hobby saw.

Initially I wasn’t sure how to do this. I’ve gone for a doughnut shaped fitting with the idea that it will be a really snug fit around the tube, free to rotate yet letting in the absolute minimum air.

My idea is to fit the canard and for now just micro in the bottom of the doughnut fitting. I used some hot glue to keep the top piece in place. It was quite challenging.

After cure you can see the bottom is in place now, in the exact correct place. The gaps are easily filled later.

A bit is happening here, not just a mess. I have made a bed of micro for the canard to sit on and then bolted the canard into the final position. Next I hot glued the top of my doughnut ring to the bottom half. It took a little doing. Now I’ve added micro to connect the top of the ‘ring’ to the underside of the canard without anything sticky touching the fuselage. The concept is after cure, I’ll remove the hot glue and the canard should come off with a perfectly located bearing ring of phenolic in place. Half on the fuselage and half on the canard.

After this I have some filling work and I need to ensure the canard goes on easily too. This will mean a bit more filing and filling so the two halves allow easy removal and a perfect seal.

While doing the tube and bearing sealing I thought I could also seal up between the canard and the front edge of its fitting area. There is a really big gap there. I’ve gone for a three inch wide 3 ply BID to stick in the hole.

That area in front of the canard is my unattractive glass strip which I hope, after cure, will become a simple air blocking forward lip extension.