| Date: 05-25-2016 | |

| Number of Hours: 5 | |

| Manual Reference: 12-1 |

After the holes have been drilled out and the tubes fitted I needed to secure the nutplate for fixing. I also found that one tab was just slightly away from F22 so I added a ply of BID to its back.

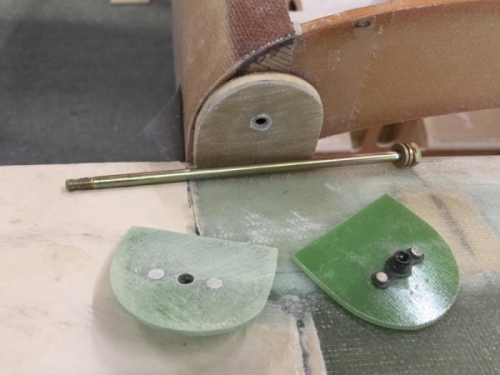

Anyway I have the nice Garolite G10 and secured a couple of nut plates to pieces. You can see I countersunk the holes and made it all pretty. The surfaces were roughened for the flox too which went on after a thin coat of epoxy.

Rather than making a smaller backing plate and covering it with BID, I’ve gone for plates full size. The twisting forces will now transfer to the top surface of the canard so all I have to do is secure the plate to the tab and it will be …super secure.

You can see the hardware in pic 1. Those AN3-55A are not cheap and it looks like a -54 would work better! I had to get a drilled one as undrilled were o/s and really …its mainly in shear.

Pic 3 has the canard secured. Oh and did I mention another 5 hours or so of sanding the canard profile. I don’t even want to talk about it or log it. Looks like that is pretty much done too.

Pieces ready

Floxed in place

Canard secured