| Date: 12-04-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 11-1 |

The usual prep took place. A days work.. well yesterday really. Cutting glass to size for the 8 plies top and bottom. Both cores can be done at once which was nice. Plans have you 5mt epoxy them to boards. I used the minimum epoxy and mainly on the TE which is later removed anyway for the glass to glass bond at the edge. I did a lot of masking and checking and this should work out.

Pic one shows the cores with micro and a wipe of pure epoxy on the metal tube. I’m shooting for a low weight per plans however the technique is pretty much the same as we have done with everything else.

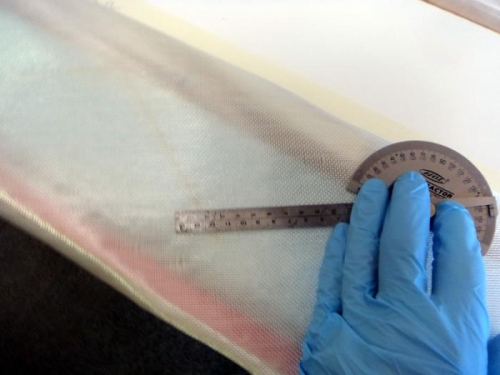

Pic 2 might suggest I’m a bit fussy with the ply orientation. Its just as easy to get it close to spot on as it is to be 5 degrees out. What would you choose?

Pic 3 show that I have the two ply on each elevator. Wow and it didn’t take all day. What a nice change to do a layup that doesn’t go from sun up to after dark.

I made it as dry as I could, even used the hairdryer although I didn’t seem to get much more epoxy off with it. Using the roller seems the key and then the squeegee. Great tools. Even though its a warm day the heater is still on in the room overnight so I can trim and clean up tomorrow. Should be good to go early afternoon.

Taped, microed and secure

30 degrees for sure

2 ply done