| Date: 06-20-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 19-6 |

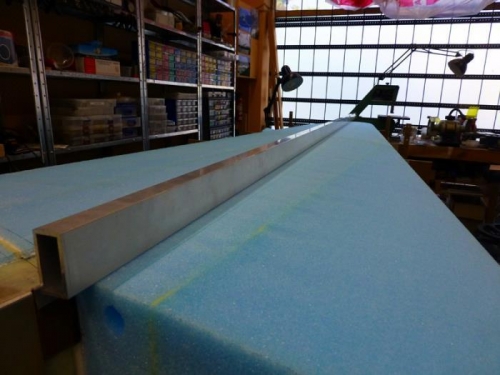

More checking for a straight wing spar cap area. More getting it really straight with little sticks and that end board in place in the second pic.

Then lots of plastic protection, plenty of tapes at the cap edges and finally cutting the glass to size and numbering everything. Cutting out peel ply and plastic and my foam boards for weight too after the job is done

I’ve measured my troughs and the caps will come out exact around the thickest area BL55.5 but a bit below the wing surface elsewhere. I have a nice fit at the tip of .05 which is definitely two full length plies.

The UNI lengths are adjusted in the CP’s to allow for thinner UNI than plans but the BL and the lengths given don’t make sense as you end up with incorrect overlaps with a longer ply above a shorter one. Its a minor glitch and just means a couple of lengths have to be swapped. Of course my brain took a while working it all out…

Here are my numbers…

1st BL 23 (0″) Full length to the tip 142″

2nd*BL 25 (-2″) to the tip 140″ (not BL130 per the CP)

3rd BL 28 (-5″) 107″

4th BL 35 (-12″) 84″

5th* BL 40 (-17″) 59″ to BL 95 (not BL90 per the CP)

6th BL 42 (-19″) 52″ to BL 90

7th BL 26 (-26″) 17.5″.

More straightness checking

More getting it right

More protective prep