| Date: 02-09-2019 | |

| Number of Hours: 11 | |

| Manual Reference: no ref |

With the cuffs in place the next step is to secure them with six hard points per side. While there are quite a few steps, it is a straightforward process.

I measured and re-measured where these hard points would go. The underneath set is just in front of the wing spar and then another two 4″ back from the pod pylon. I finally took the step to drill the 3/32″ holes and then added clicos to ensure I had it secure. This took half a day, maybe other people would take half an hour. Its not every day I drill into my wings.

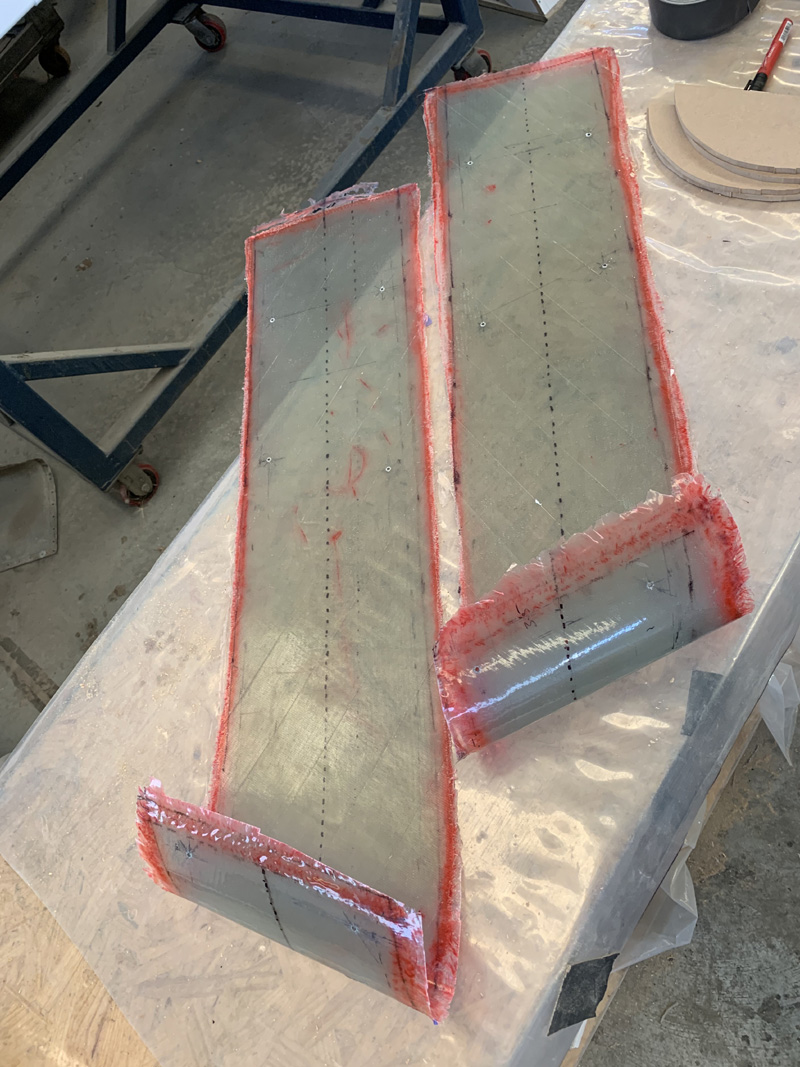

Next up was to pop off the cuff layup. It was pretty easy proving again that some shinny tape with no other prep works a treat for release.

I then got all the tapes off, Did a slight trim of the residue and again secured the cuff with clicos. Given the thickness of the release tape I wanted to see if the cuffs were sloppy. Nope, still a tight fit.

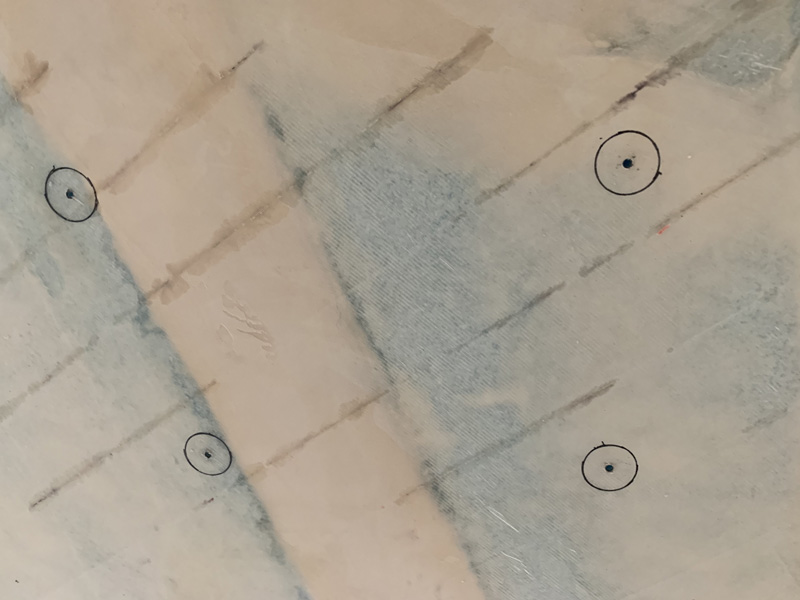

Next up I removed the cuffs again and used 3/32″ diameter counter sunk screws to secure the AN960 washer to the wing. The idea is that the countersink area centers the washers. I then drew around the washers with a fine tip Sharpie pen. This process is for later lining up to get the hardpoints very close to perfectly centered.

Here’s the bottom of the wing after I removed the washers and screws. Now we have circles centered around the holes that are in the cuff transferred to the wing.

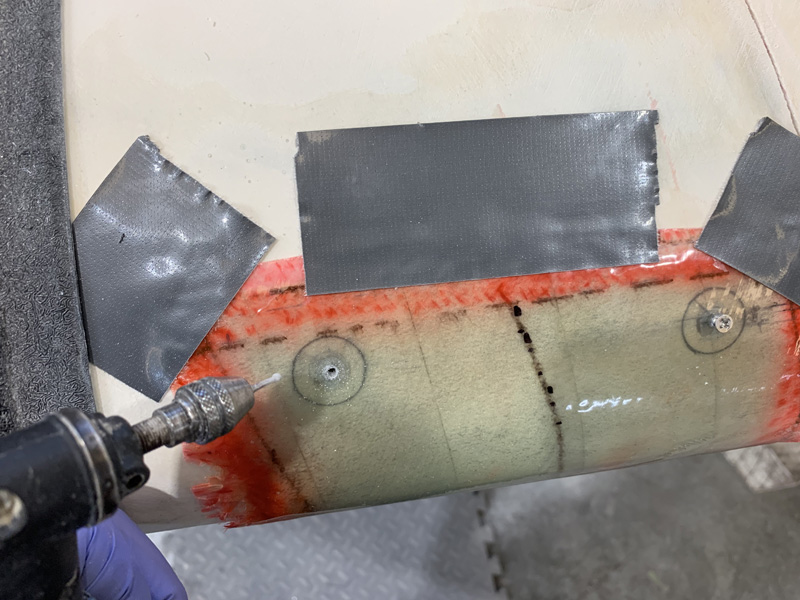

I’m using 1″ long aluminium hardpoints. To install them its an assembly of a washer with grey duct tape for release trimmed on one side of the washer, a screw as a handle and a lock nut.

I opened up the 3/32″ holes in the wing to 7/16″. I used a drill with a crooked bit of wire about 3/8″ at right angles so I could clear some blue foam just under the skin making a mushroom shaped cavity.

I then made a mixture to fill the cavities for potting the hardpoints. The mix was 25 grams of mixed epoxy, 3 grams of flox and 1 gram on micro. This makes a nice thick paste for the job and worked well even though 4 of the 6 hardpoints per wing are upside down. Of course I primed the hardpoints with pure epoxy and then added some of the mixture. I also primed the holes with epoxy before working in the flox paste mixture. The usual things we do.

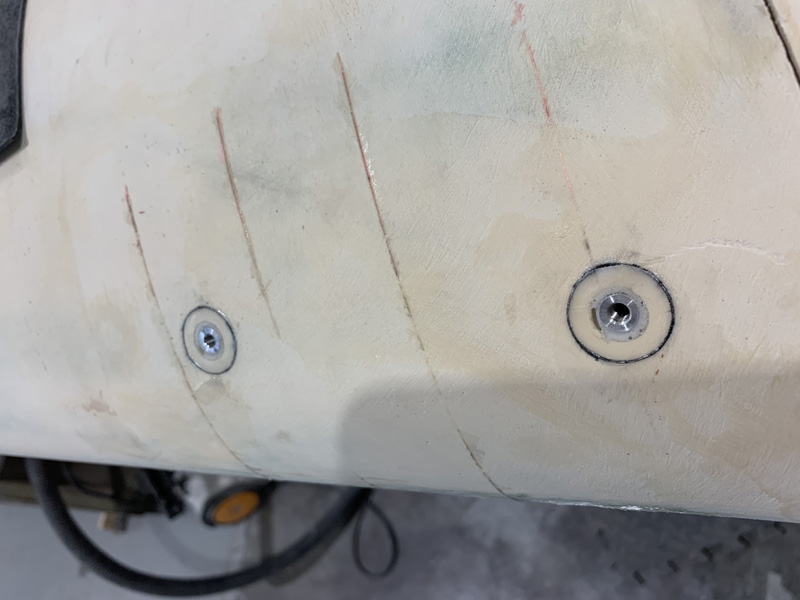

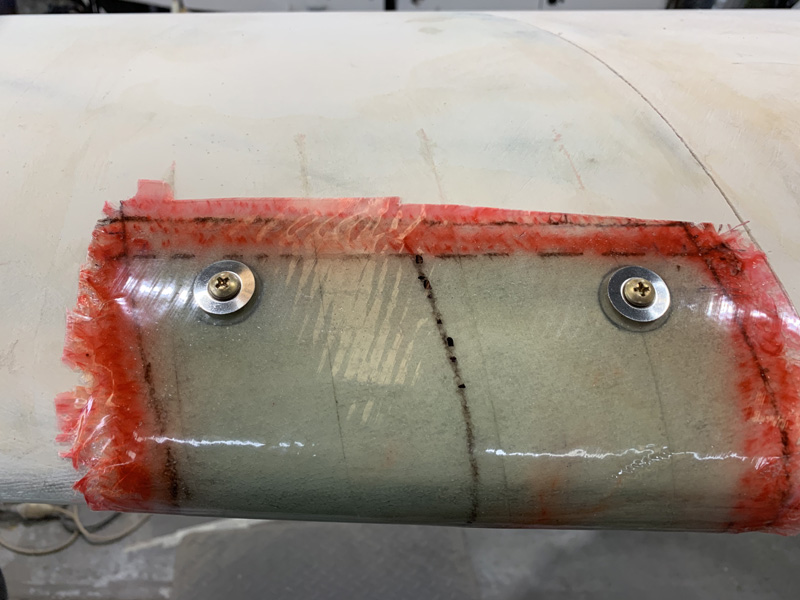

The assembly can move a bit in the hole when wet and thats where the drawn circles allow you to center them very well. I used tape to secure for the cure. As you can see after the cure and removing the tape we have our hardpoints centered in the circles. They are also at right angles to the surface. Perfect. This was all in the pod install instructions and it works.

The bolts came out easily and the washers popped off with a little encouragement. We have hardpoints!

They lined up very closely to the centers of the 3/32″ holes in the 7 ply cuff layup. I just used the dremel to get the centers perfect and then drilled them up to 3/16″

Later these will be countersunk and countersunk screws used. For now I’m happy just to add the tinnermans and have the cuff screwed on the wing correctly.

This is under the wing. I’ll trim the cuff after the pylon and pods are fitted. For now I’m happy to move on to fitting the pods themselves to these cuffs.