| Date: 06-25-2022 | |

| Number of Hours: 10 | |

| Manual Reference: 22 |

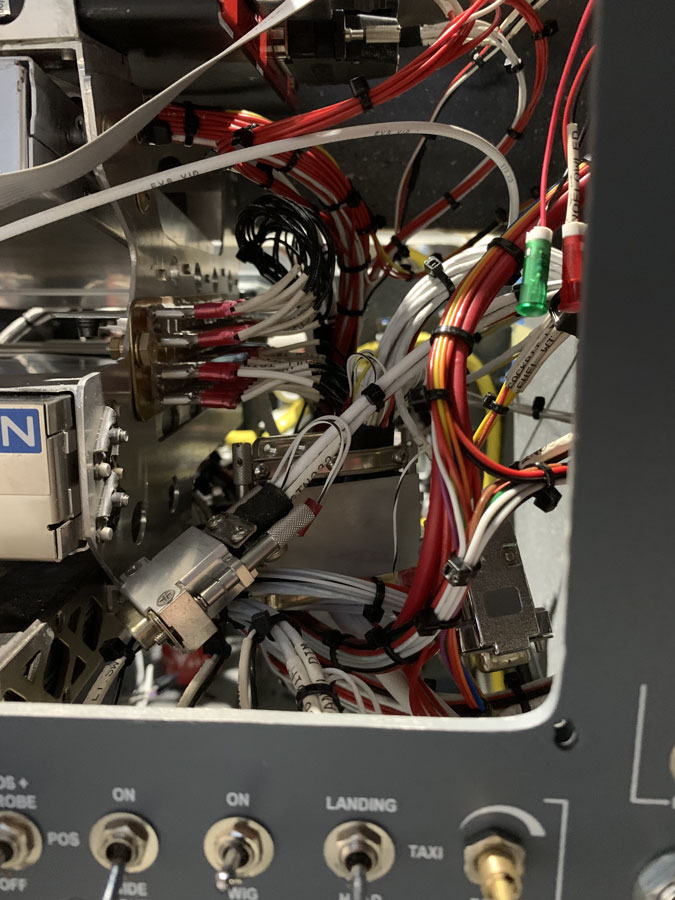

We again hit it pretty hard this week, or rather my UN-named avionics expert continued to do the work. I hovered and had an occasional bit of homework or maybe ‘pass the heat gun’. Yes every single wire is labeled at both ends with printed heat shrink.

We now have put the smoke in the wires and none came out! There are a few tweaks and adjustments still to do. The major work is done until the engine shows up. Then final wiring, additions to the looms, tie down fixing points and cleaning up can get us nearer the finishing line.

It turns out one of the autopilot servers is u/s or NFG. It never saw even one hour of use. However, the way Garmin works I will have to pay for the repair or replacement. There is no warranty as they runs from date of purchase, not date of in service. We experimental builders get no respect. My concern is the delay this may cause with back-orders being a problem. This is Mondays job to get it all moving.

Meanwhile, lots of good news getting this far and hours of configuration still to come. Its a relief to see light in the panel. Gratuitous pics follow.

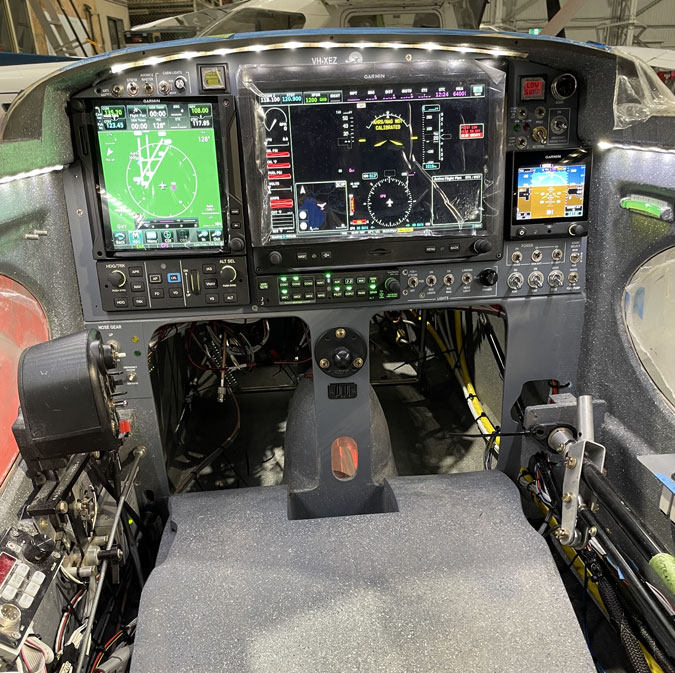

Yes it all fits…just. White lighting or red, both ‘dim-able’.

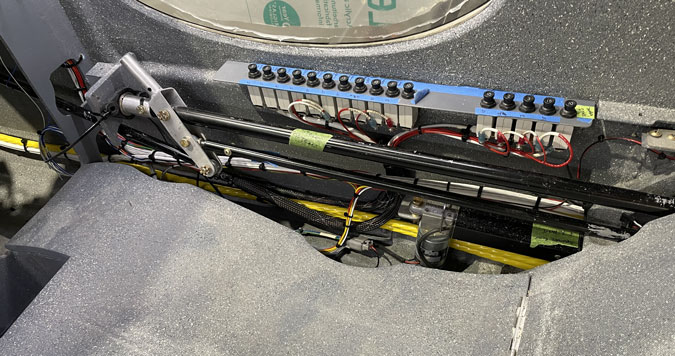

Circuit breakers waiting for the engine to be completed.

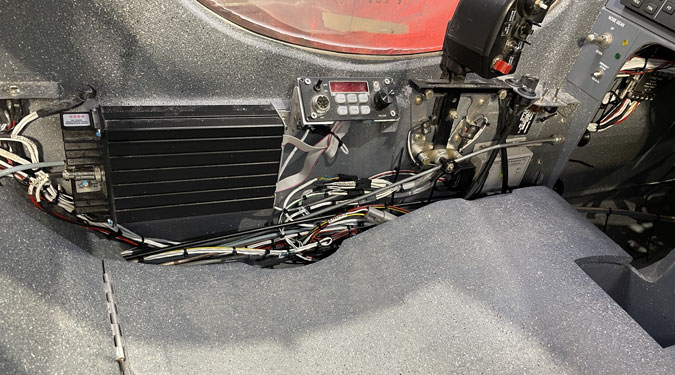

Throttle and HF all in. A push pull cable to be secured and some wall fasteners later.

The mysterious, un-named avionics expert, who is too busy to work on your plane, captured via the inbuilt EVS infrared forward facing camera.

The red works. At this stage I have no idea what I’ll want to fly with, red or white? I usually prefer red wine.

The money shot.

We still have a lot of work to do but now the avionic finishing line is much closer.

I had to recut the panel for the final fitting of the GTN750. Careful dremel work followed by hand filing.

The audio panel didn’t fit correctly for this final step. After some discussion, I removed the plastic front cover, trimmed it between 1mm and 2mm and the result was a ‘no regret’ fit.

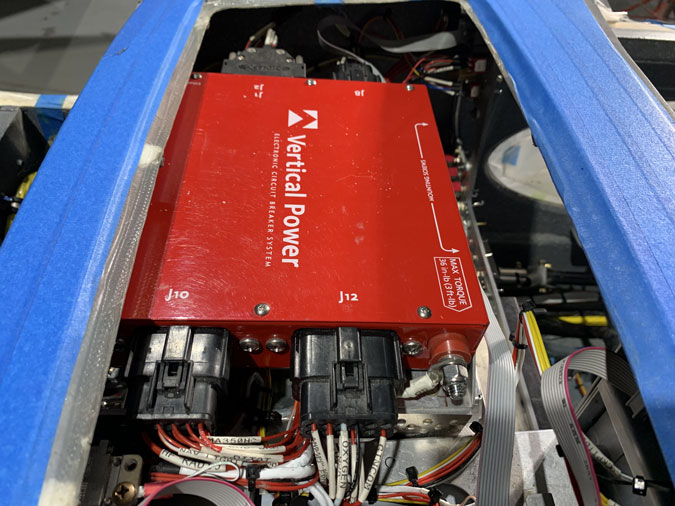

The VPX may not have been necessary for this build as we also went with old school breakers for critical engine function. We still used a lot of its capacity and electronic fusing is a nice feature. Plan B would have been a LOT of fuses under the seat and some even longer wire runs.

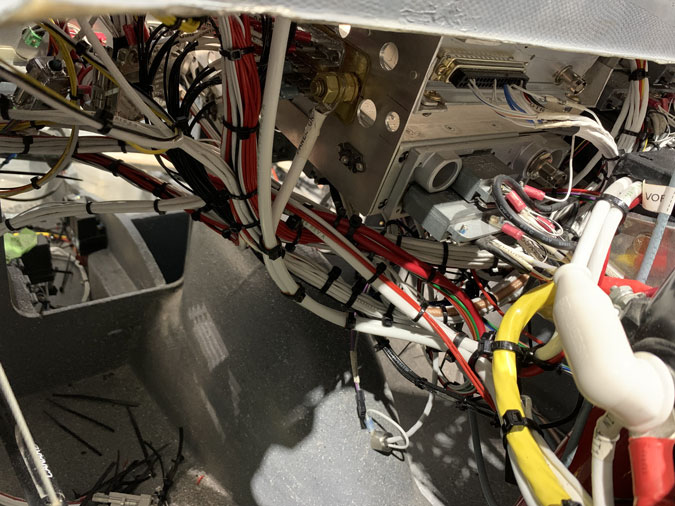

This is amazingly tidy given the space constraints. We still have final clean up and a few more wires to go in.

It’s busy in there.