| Date: 12-25-2023 | |

| Number of Hours: 3 | |

| Manual Reference: 23 |

Sometimes you see something that you are not happy with and you know it will come back to bite you one day. So you need to fix it. Better right away than nagging at the back of your mind. While working on the hoses I noticed that the wire at the back of the standby alternator was almost touching the hatch cover.

I had a allowed for this but by the time some RTV and foil had gone in, the gap had quietly closed. So all the vents that had been finalised with torque seal and buttoned up had to come out again to get access.

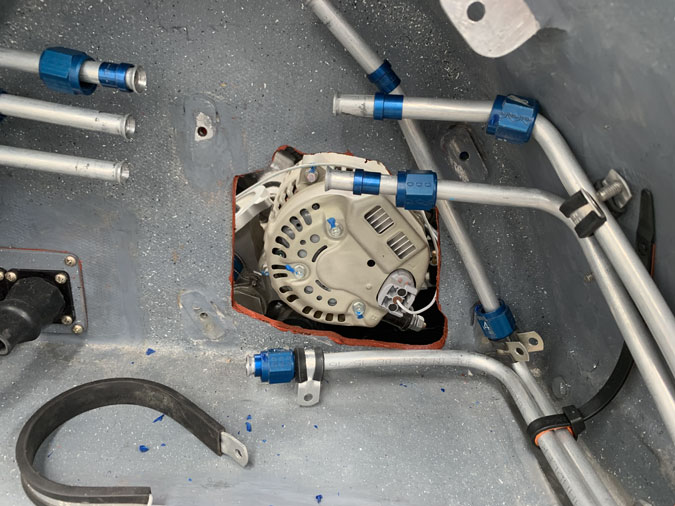

You can see with things out that white wire on a plug at the back of the alternator? This is what needed just a little more clearance.

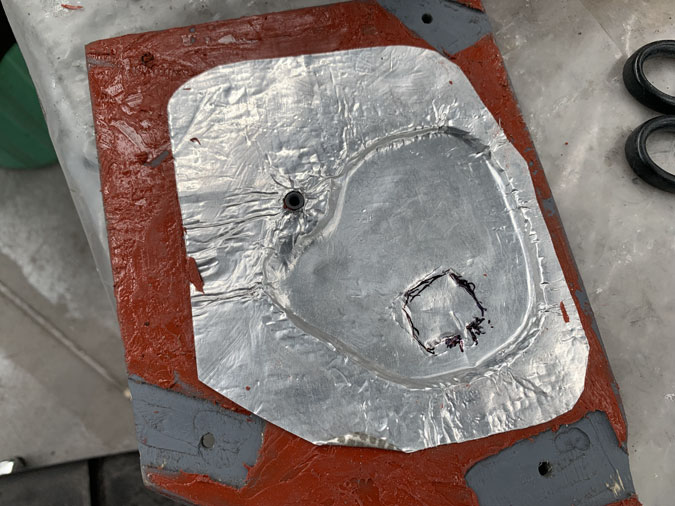

I could barely get a pen on it from the other side to ensure I was digging in the right place. I had allowed for this, just not quite enough.

I went right down to the point where I was just breaking through the plywood. A reasonable depth, otherwise I would have needed to add to the outside.

Given I had gone through, a ply of glass was needed to lock things together. Of course I also needed to get the paint off first.

Once cured, primer and top coat. Yes I am probably the only person who will ever see this.

On the other side I just added a solid but thin coat of RTV which is proven to work in a fire as a barrier.

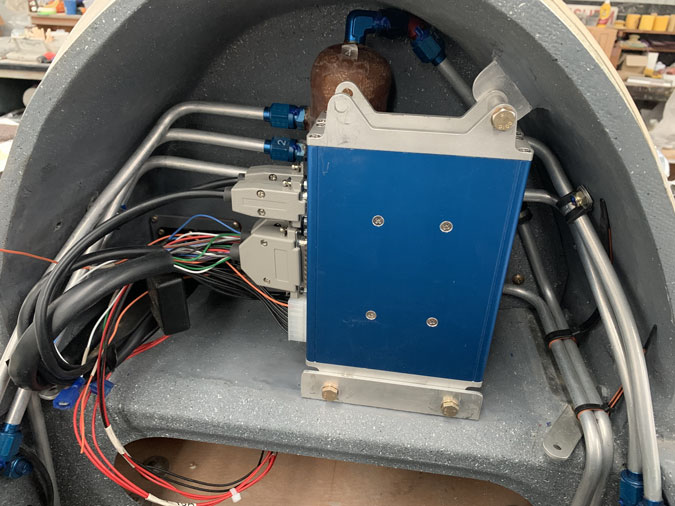

All the ‘stuff’ then went back in.

Here’s a view from the engine side. Its hard to spot but I am finally happy with the clearance for that one white wire. Time to move on.