| Date: 12-10-2015 | |

| Number of Hours: 5 | |

| Manual Reference: 19-9 |

Plans say 3/8 steel rod for the counter balance. Experienced builders suggest 7/16 steel rod. Some others, well respected, suggest 7/16 tube with lead fill so the weight can be adjusted after fill and paint of the ailerons to get a perfect balance. That’s my plan.

65″ 7/16 mild steel weights 1247.4 grams

65″ 4130 tube 7/16″ with 0.058″ wall comes in at 576 grams add 7.5mm diameter lead and you get 1380.9 grams

OK so 7/16 tube and lead gets me an extra 134 grams over just rod. BUT it is also adjustable by removing some of the lead which slides in and out of the tube with a bit of care. I’ll secure it with epoxy when final weight is achieved. This has taken a lot of sorting out and I hope it works!

Pic 1 shows the 4130 with the lead inside, a mild steel rod and an empty tube. Yes the lead is really floppy and takes a bit of straightening out.

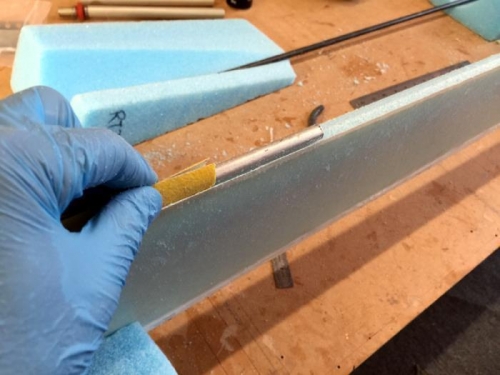

Pic 2 shows me making the slot for the counter balance. I first route a slot with the dremel and then finish off with sandpaper wrapped around a bit of aluminium tube.

Pic 3 has me close to a good fit for the tube on the aileron. This gets microed on later and I’ll still be able to adjust the weight by sliding in the lead rod.

4130 lead and steel

Making the groove

Fitting the balance rod